Raw material powder storage device and application method thereof

A storage device and powder technology, applied in the field of brown sugar processing, can solve the problems of flying brown sugar powder, air pollution, brown sugar waste, etc., and achieve the effects of reliable operation, low manufacturing cost and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

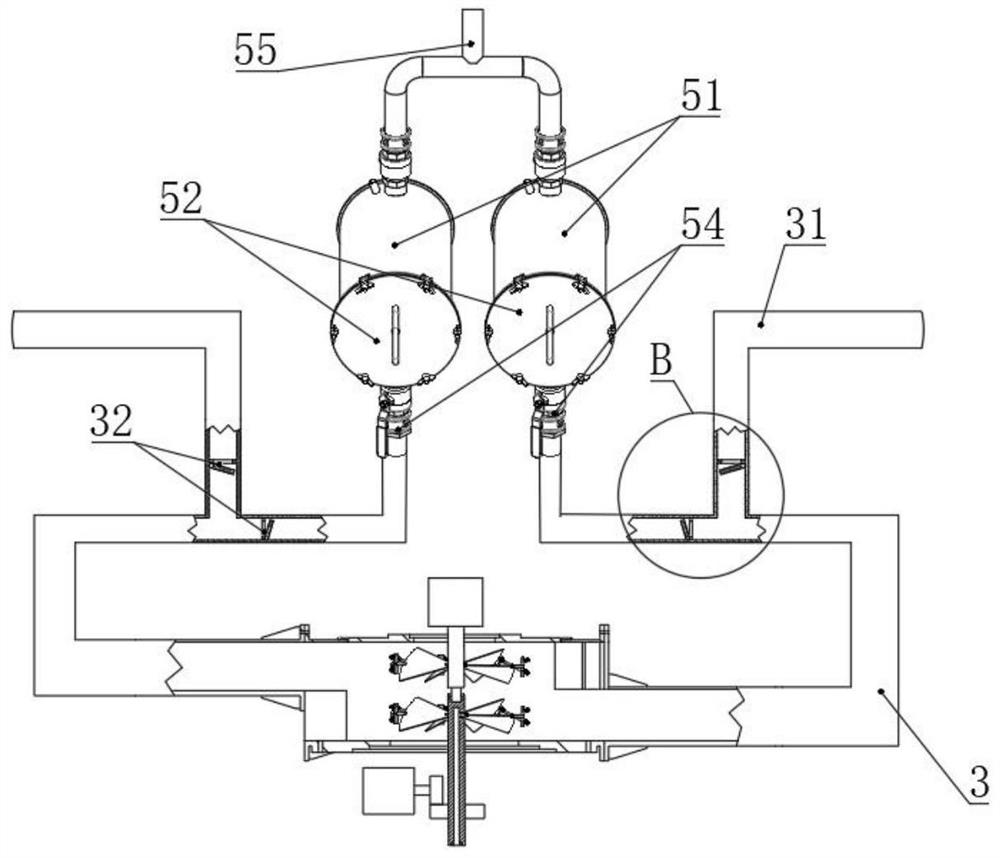

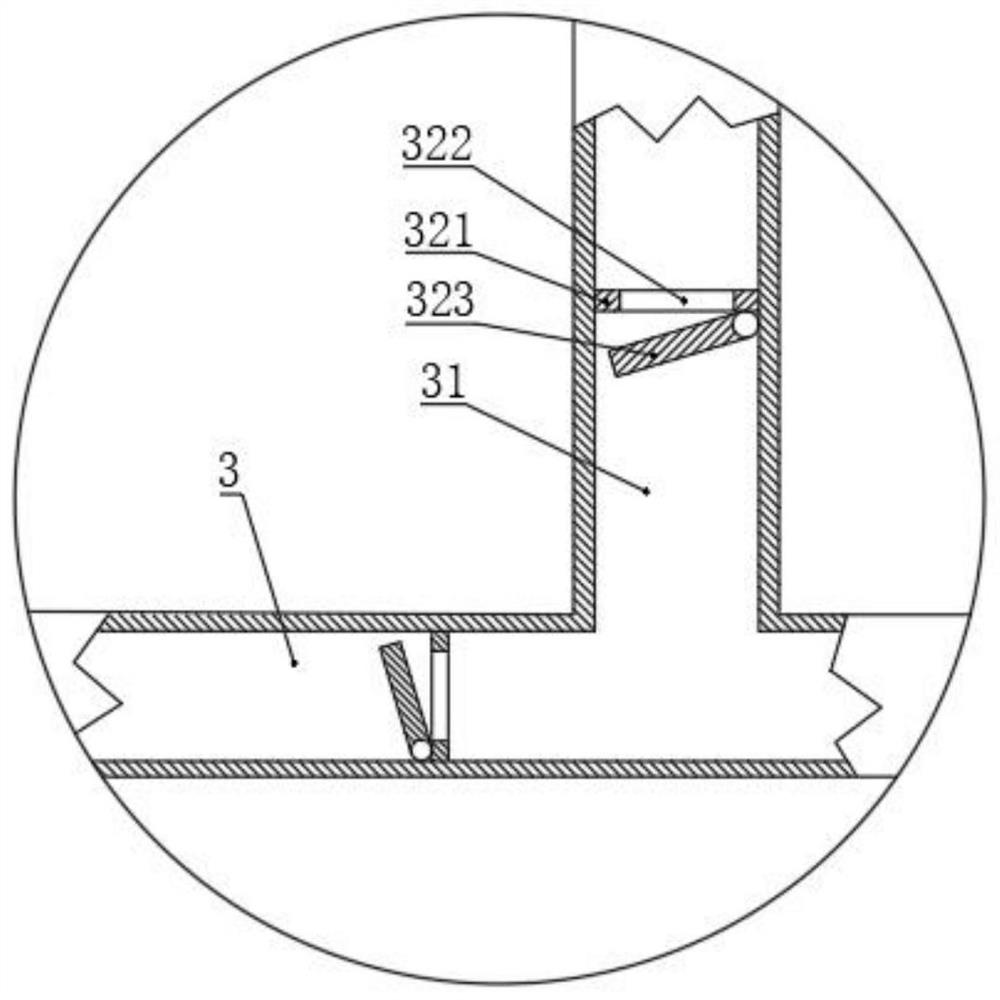

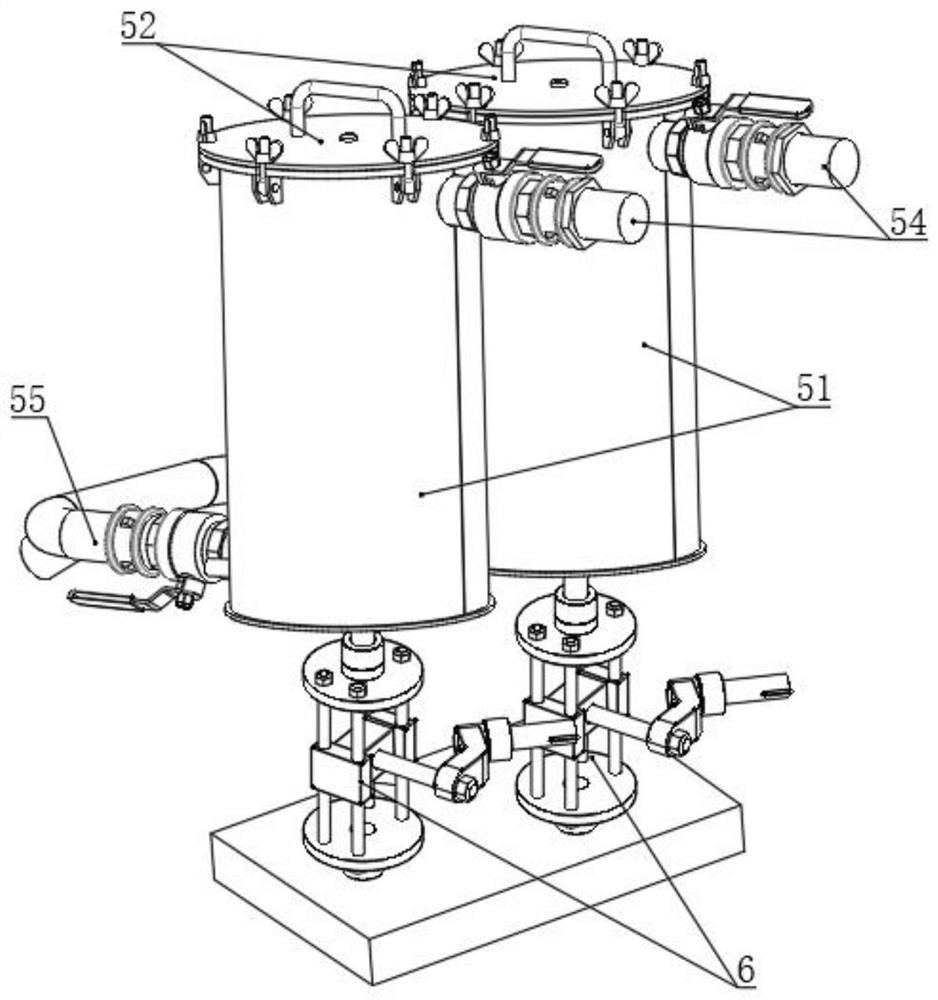

[0068] Such as Figure 1-8 As shown, a raw material powder storage device includes two collection mechanisms, and a power mechanism 6 is installed under the two collection mechanisms;

[0069] Collection mechanism comprises outer barrel wall 51 again, is installed on outer barrel wall 51 top and the bung 52 that is detachably connected with it, and the outer barrel bottom 53 that is fixedly installed on outer barrel wall 51 below, and outer barrel wall 51 is also provided with collecting inflow pipe 54 and collection outflow pipe 55;

[0070] An inner barrel 56 is also installed inside the outer barrel wall 51, and the inner barrel 56, the outer barrel wall 51 and the bung 52 form a first space 57, and the inner barrel 56, the outer barrel wall 51 and the outer barrel bottom 53 form a second space 58, and the collection inflow pipe 54 It communicates with the first space 57 , the collection outflow pipe 55 communicates with the second space 58 , and the inner barrel 56 is fle...

Embodiment 2

[0090] This embodiment is a further improvement of the previous embodiment, such as Figure 1-8 As shown, a raw material powder storage device includes two collection mechanisms, and a power mechanism 6 is installed under the two collection mechanisms;

[0091] Collection mechanism comprises outer barrel wall 51 again, is installed on outer barrel wall 51 top and the bung 52 that is detachably connected with it, and the outer barrel bottom 53 that is fixedly installed on outer barrel wall 51 below, and outer barrel wall 51 is also provided with collecting inflow pipe 54 and collection outflow pipe 55;

[0092] An inner barrel 56 is also installed inside the outer barrel wall 51, and the inner barrel 56, the outer barrel wall 51 and the bung 52 form a first space 57, and the inner barrel 56, the outer barrel wall 51 and the outer barrel bottom 53 form a second space 58, and the collection inflow pipe 54 It communicates with the first space 57 , the collection outflow pipe 55 c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com