Full-automatic steam curing equipment for aerated concrete building materials

A fully automatic technology of aerated concrete, applied in auxiliary molding equipment, ceramic molding machines, manufacturing tools, etc., can solve the problem of aerated concrete blocks being difficult to separate due to adhesion, bonding surfaces that cannot be steamed and dried quickly, and boards steamed Incomplete drying and other problems, to achieve the effect of simple and reliable structure, conducive to separation, and power saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

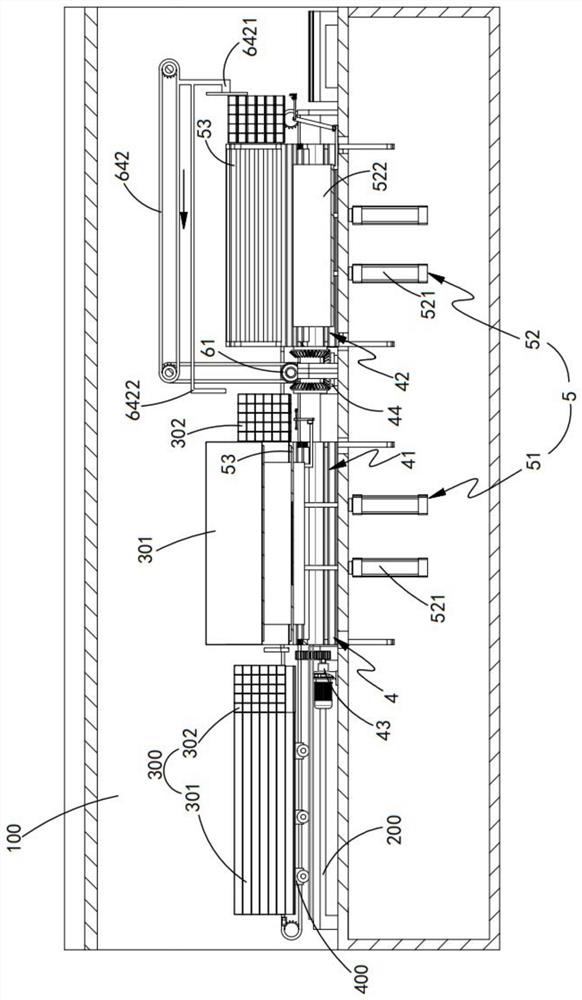

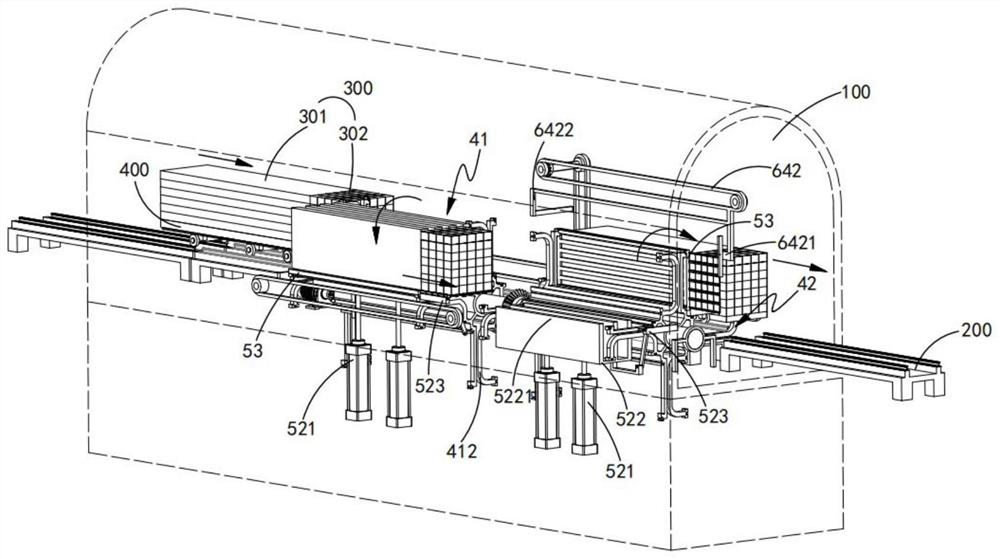

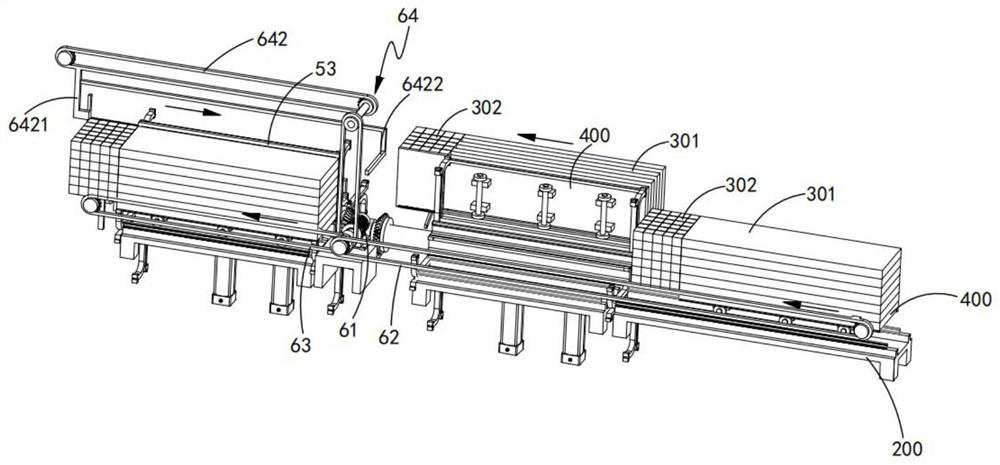

[0045]Such as Figures 1 to 3 As shown, a fully automatic steam curing equipment for aerated concrete building materials includes a steam curing bin 100, a conveying rail 200 penetrating through the steam curing bin 100, and a conveyor for carrying concrete building materials 300 arranged on the conveying rail 200 The transport cart 400, the concrete building material 300 includes a plate 301 and a brick 302, and is characterized in that it also includes a turning mechanism 4 and a partition shifting mechanism 5, and the turning mechanism 4 drives the transport cart 400 together with the concrete building material 300 Turning along the vertical plane, the partition shifting mechanism 5 lifts the turned boards 301 at intervals to form a dislocation and pulls the turned bricks 302 apart laterally.

[0046] It should be noted that the transport trolley 400 transports the concrete building materials 300 stacked in flat layers into the steam curing bin 100, the overturning mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com