Anti-rutting asphalt and preparation method thereof

An anti-rutting and asphalt technology, applied in the field of anti-rutting asphalt and its preparation, can solve the problems of difficult rutting maintenance, affecting high-speed driving, road surface damage, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-5

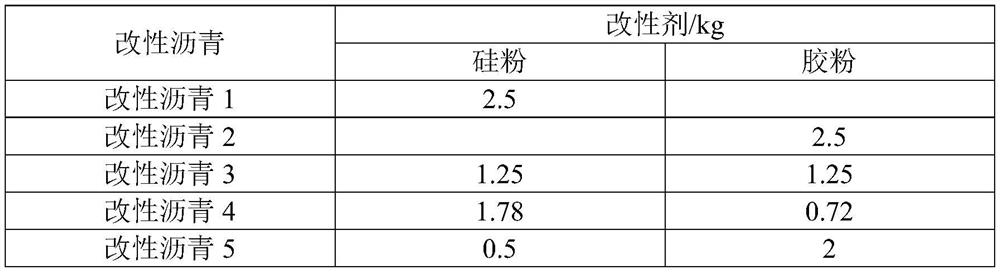

[0050] Modified asphalt preparation examples 1-5 differ only in the choice or amount of modifier. Modified asphalt preparation 1-5 modifiers and specific dosage are shown in Table 1 below.

[0051] Table 1 Modifiers used in modified asphalt 1-5 and their specific dosages.

[0052]

Embodiment 1

[0055] A kind of preparation of anti-rut asphalt comprises the steps:

[0056] Preparation of asphalt mixture: Mix 10kg of base asphalt, 95kg of coarse aggregate, 17kg of fine aggregate and 0.3kg of BX anti-rutting agent, and then heat at 220°C for 10 minutes to obtain hot asphalt mixture;

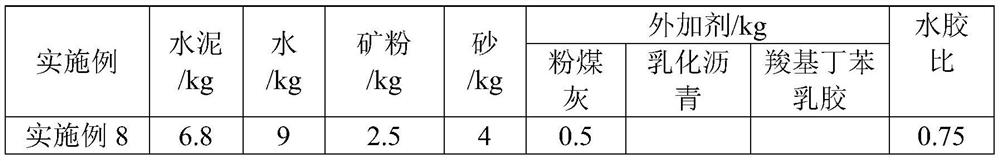

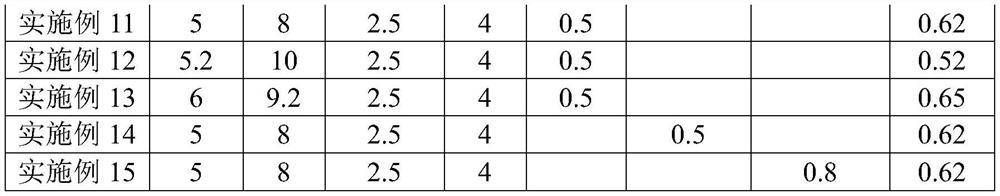

[0057] Prepare cement slurry: mix 6.8kg cement, 9kg water, 2.5kg mineral powder, 4kg sand and 0.5kg fly ash evenly to obtain cement slurry;

[0058] Grouting: Take 80kg of hot asphalt mixture and cool it down to 80°C before paving, then pour 20kg of cement slurry on the paved asphalt mixture, and cure for 7 days.

Embodiment 2-5

[0060] The difference between Examples 2-5 is only that the asphalt ratio in the asphalt mixture is different. The specific proportions in Examples 2-5 are shown in Table 2 below.

[0061] The proportioning table of table 2 embodiment 2-5

[0062] Example Base bitumen / kg Coarse aggregate / kg Fine aggregate / kg Oil stone ratio% Example 1 10 95 17 9 Example 2 3 80 20 3 Example 3 5.2 85 15 5.2 Example 4 3 100 20 2.5 Example 5 5 100 10 4.5

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com