Method for catalytically degrading polyethylene glycol terephthalate

A technology of polyethylene terephthalate and polyethylene terephthalate, which is applied in the field of catalytic degradation of polyethylene terephthalate, and can solve the problems of non-recyclability and high cost of metal ionic liquid catalysts , to achieve the effect of green environmental protection, high yield and low temperature in the preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) After cleaning and drying the waste PET bottles, place them in a pulverizer and pulverize them to obtain waste PET fragments with a size of 5 mm.

[0041] (2) Weigh 2g of waste PET chips and 2g of zinc hydroxide, put them into a ball mill, stir and mix at a speed of 50r / min for 20min, and obtain a homogeneous mixture of the two.

[0042] (3) Transfer the mixture obtained in step (2) to a crucible, put the crucible into a tube furnace, set the tube furnace to heat at a heating rate of 5°C / min, rise to a reaction temperature of 240°C, and Keep warm at high temperature for 60 minutes, and the amount of water vapor introduced is 0.4g.

[0043] (4) After the tube furnace is naturally cooled, the solid product in the crucible and the liquid product in the condensing device are obtained. Soak the solid product in the crucible in 0.5mol / L hydrochloric acid solution for 0.5h, and filter and separate.

[0044] The white solid in the upper layer can be washed and dried to ob...

Embodiment 2

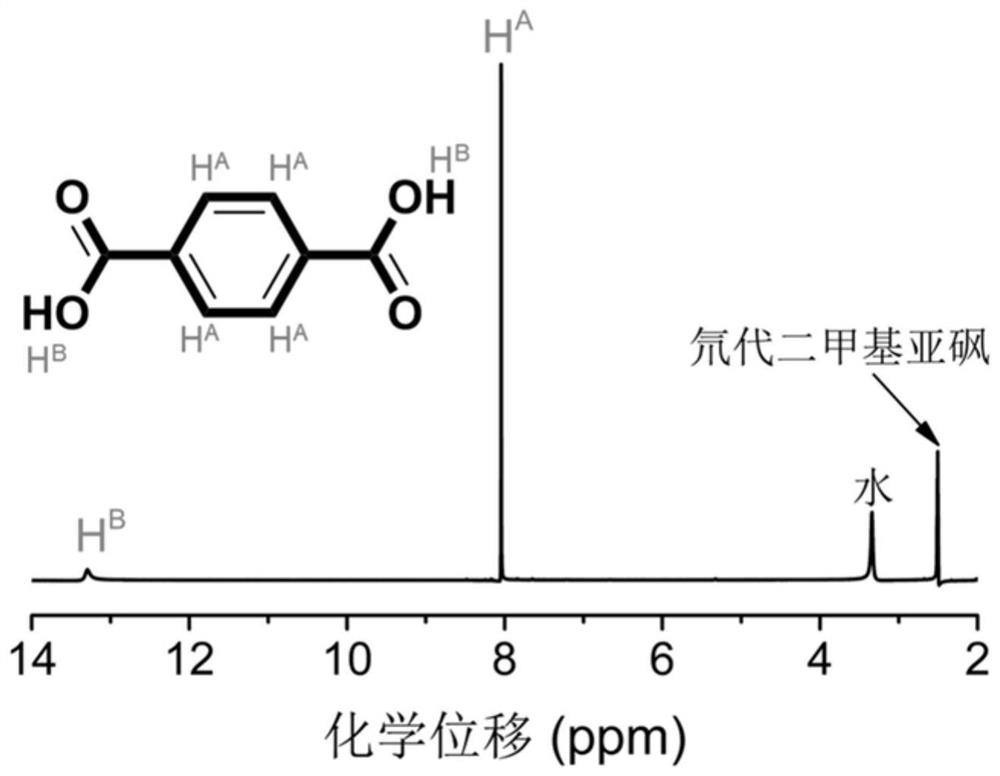

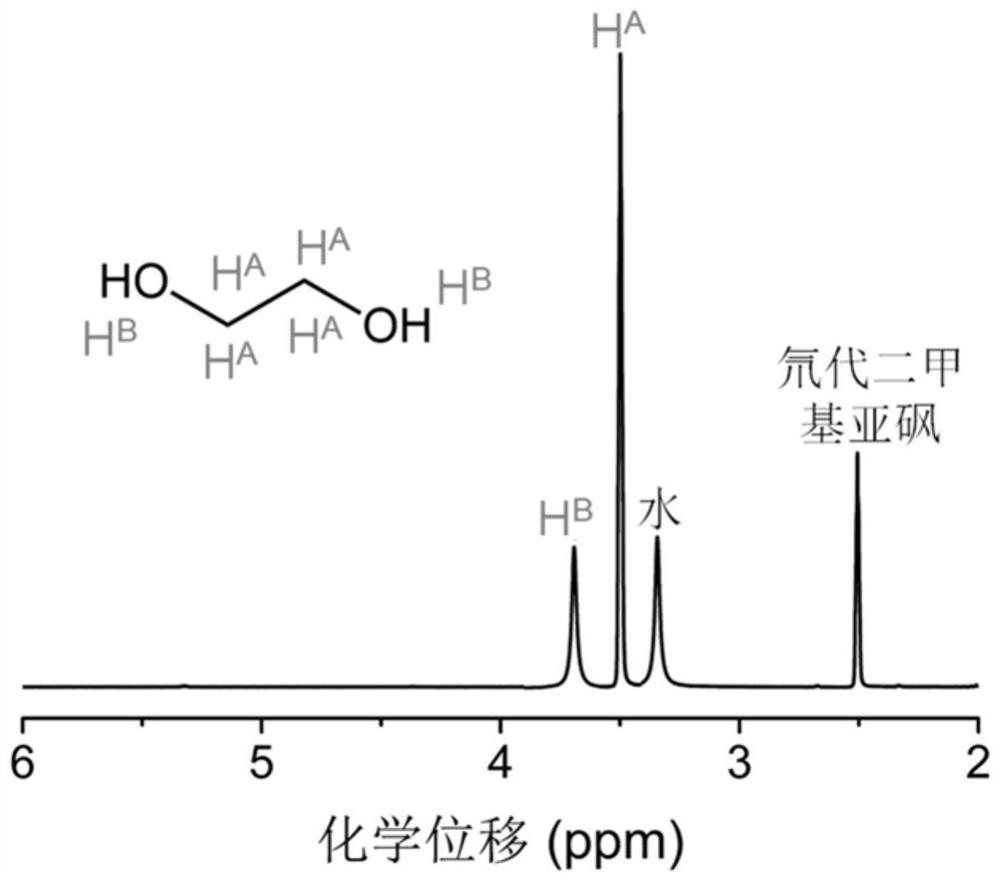

[0046] The difference between this example and Example 1 lies in that the reaction temperature is 200° C. and the reaction time is 90 minutes, and the colorless liquid of ethylene glycol and the white powder of terephthalic acid are obtained, and the yields are 93 wt % and 92 wt %, respectively. The H NMR spectra of prepared terephthalic acid and ethylene glycol are respectively as follows figure 1 with figure 2 As shown, this indicates that the purity of the prepared terephthalic acid and ethylene glycol is very high, close to 100%.

Embodiment 3

[0048] (1) Wash and dry the waste PET bottles and place them in a shredder to obtain waste PET fragments with a size of 1 mm.

[0049] (2) Weigh 2g of waste PET chips and 8g of zinc hydroxide, put them into a ball mill, stir and mix them at a speed of 100r / min for 10min, and obtain a homogeneous mixture of the two.

[0050] (3) Transfer the mixture obtained in step (2) to a crucible, put the crucible into a tube furnace, set the tube furnace to heat at a heating rate of 10°C / min, rise to a reaction temperature of 180°C, and Keep warm at high temperature for 120min, and the amount of water vapor introduced is 0.4g.

[0051] (4) After the tube furnace is naturally cooled, the solid product in the crucible and the liquid product in the condensing device are obtained. Soak the solid product in the crucible in 0.5mol / L hydrochloric acid solution for 0.5h, and filter and separate. The white solid in the upper layer can be washed and dried to obtain terephthalic acid powder with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap