Corrosion-resistant high-strength high-toughness alloy tool steel and heat treatment method and production method thereof

A technology of alloy tool steel and heat treatment method, which is applied in the field of corrosion-resistant, high-strength, high-toughness alloy tool steel and its heat treatment, and can solve the problem that alloy tool steel wire rod does not have toughness, products and achievements are blank, and there are few high-strength and high-toughness materials, etc. problems, to achieve the effect of excellent wear resistance, good wear resistance, good strength and plastic toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

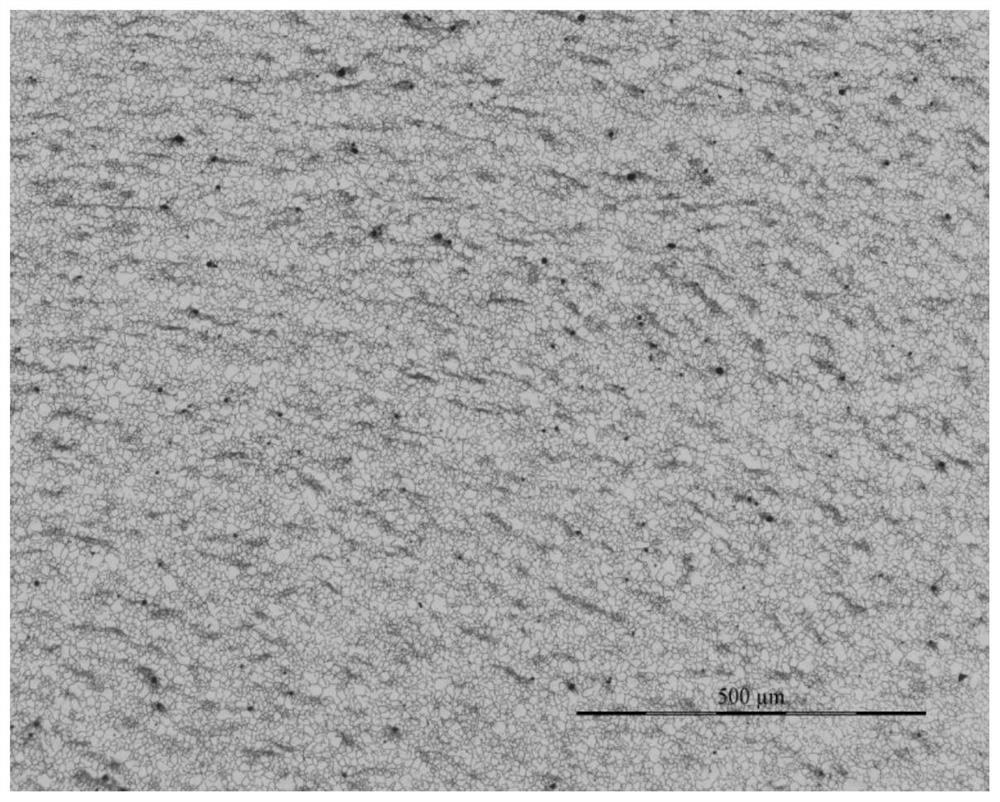

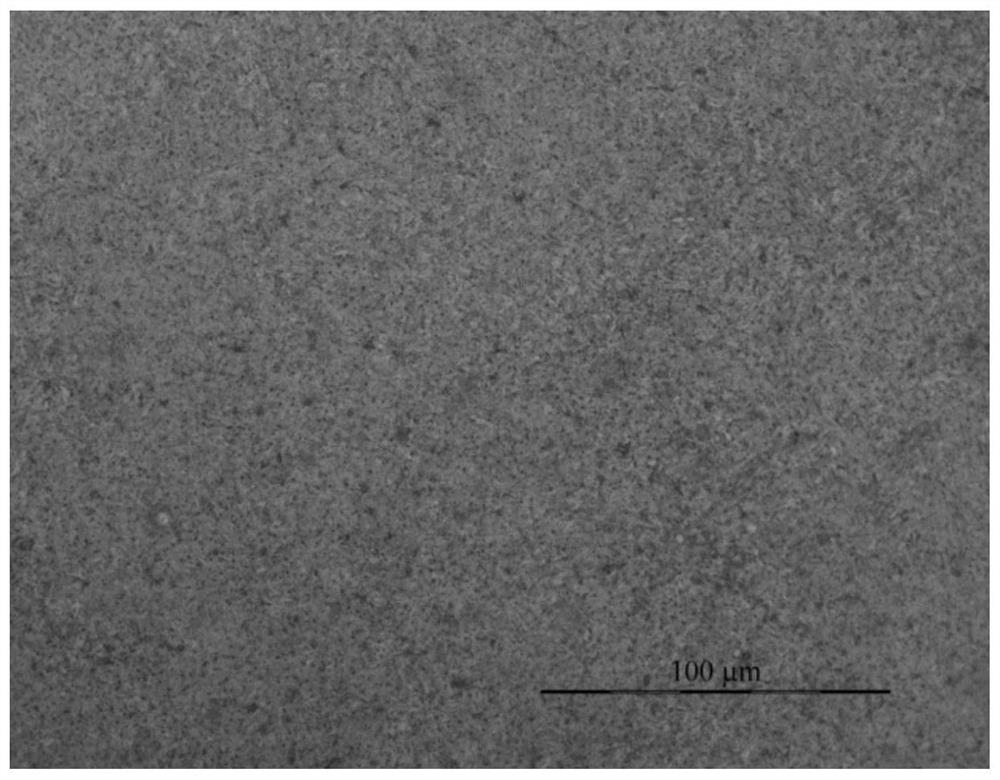

Image

Examples

Embodiment Construction

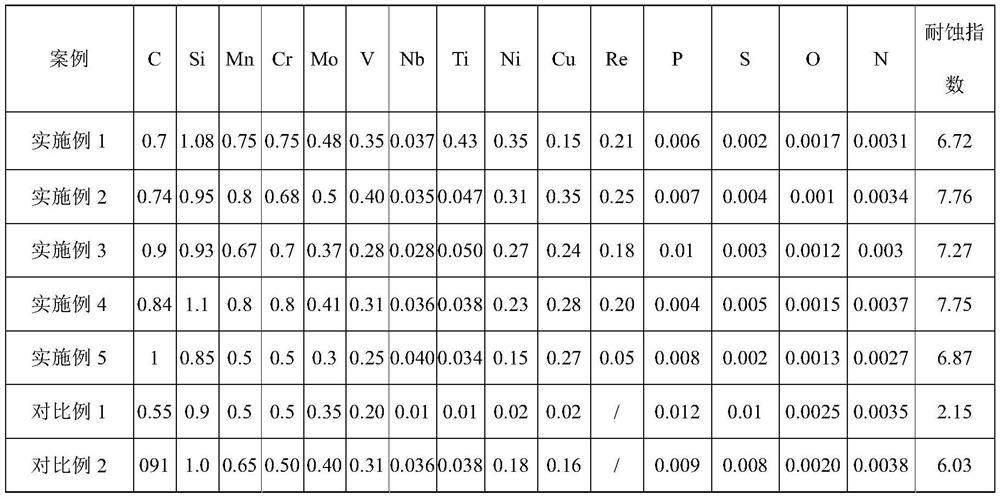

[0048] The corrosion-resistant, high-strength and high-toughness alloy tool steel provided by the invention contains the following chemical components by weight percentage: C 0.70%-1.00%, Si 0.80%-1.10%, Mn 0.50%-0.80%, Cr 0.50%-0.80%, Mo0.30%~0.50%, V 0.20%~0.40%, Nb 0.020%~0.040%, Ti 0.030%~0.050%, Ni0.15%~0.35%, Cu 0.15%~0.35%, Re 0.05%~0.25% , P trace ~0.015%, S trace ~0.015%, O≤0.0015%, N≤0.006%. The rest is Fe and other unavoidable impurities; among them, 0.50W+0.50Mo+0.26Cr+V+Nb≤1.5C.

[0049] The production method of alloy tool steel with corrosion resistance, high strength and high toughness includes the following steps: electric furnace smelting → LF furnace refining → RH or VD vacuum degassing → bloom continuous casting → billet rolling → finishing peeling → heating → high-speed wire rod controlled rolling Manufacturing→Stelmore cooling by wire controlled cooling→Finished wire rod and wire rod→Spheroidizing annealing→Quenching→Tempering;

[0050] Among them, in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com