Novel elastic tin-phosphor bronze alloy and preparation method thereof

A tin phosphor bronze and elastic technology, which is applied in the field of new elastic tin phosphor bronze alloy and its preparation, can solve problems such as unfavorable alloy performance, achieve the effects of reducing production cost, reducing loss, and improving tensile strength and yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

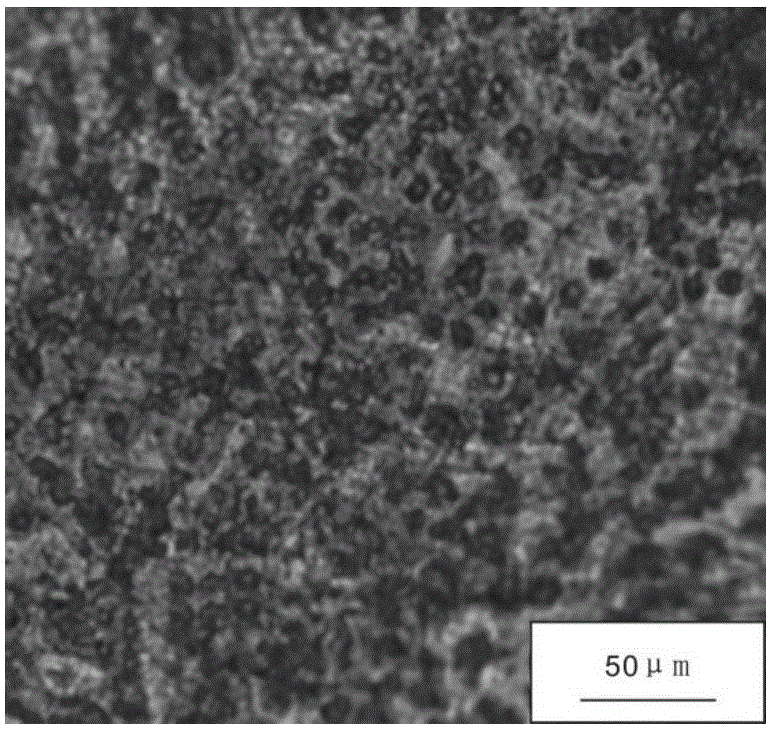

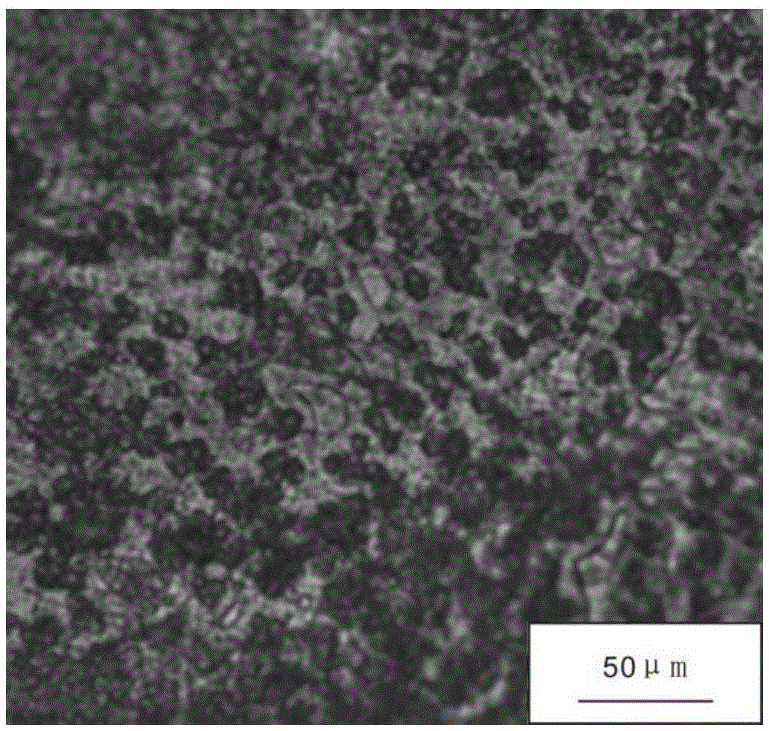

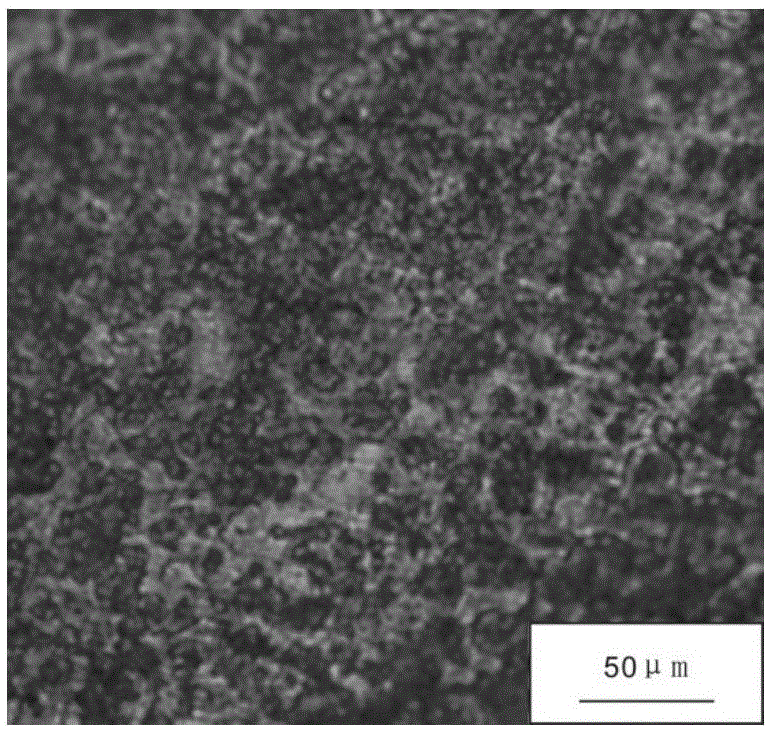

Image

Examples

Embodiment 1

[0047] A novel elastic tin phosphor bronze alloy, the mass percent of the alloy composition is:

[0048] Sn: 6.08wt%;

[0049] P: 0.14wt%;

[0050] Ni: 0.151wt%;

[0051] Al: 0.002wt%;

[0052] Zn: 0.22wt%;

[0053] Fe: 0.035wt%;

[0054] Pb: 0.01wt%;

[0055] The remainder is Cu and unavoidable impurities.

[0056] In this example, the sum of the mass percentages of Cu, Sn and P in the alloy composition is not less than 99.5 wt%.

[0057] A preparation method of a novel elastic tin phosphor bronze alloy, comprising the following steps:

[0058] a. Determination of composition: first select C5191 tin phosphor bronze waste as raw material, and measure the composition of the raw material by direct reading spectrometer;

[0059] b. Raw material smelting: the raw material is smelted in an intermediate frequency protection furnace with Ar gas atmosphere protection, and heated to 1300-1400 ℃ to keep it warm, add the master alloy, after fully melting, keep it warm for 40 minu...

Embodiment 2

[0069] Adopt embodiment 1 method to react, and its difference is:

[0070] In this example, a new type of elastic tin phosphor bronze alloy, its alloy composition mass percentage is:

[0071] Sn: 5.78wt%;

[0072] P: 0.11wt%;

[0073] Ni: 0.083wt%;

[0074] Al: 0.002wt%;

[0075] Zn: 0.22wt%;

[0076] Fe: 0.035wt%;

[0077] Pb: 0.01wt%;

[0078] The rest are Cu and unavoidable impurities; all the other are the same as in Example 1.

[0079] The copper strip sample test of step e gained, its main mechanical property is as shown in table 2:

[0080] Table 2

[0081]

Embodiment 3

[0083] Adopt embodiment 1 method to react, and its difference is:

[0084] In this example, a new type of elastic tin phosphor bronze alloy, its alloy composition mass percentage is:

[0085] Sn: 6.41wt%;

[0086] P: 0.19wt%;

[0087] Ni: 0.201wt%;

[0088] Al: 0.002wt%;

[0089] Zn: 0.22wt%;

[0090] Fe: 0.035wt%;

[0091] Pb: 0.01wt%;

[0092] The rest are Cu and unavoidable impurities; all the other are the same as in Example 1.

[0093] The copper strip sample test of step e gained, its main mechanical property is as shown in table 3:

[0094] table 3

[0095]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com