A control method for upper and lower wall broken surrounding rocks suitable for thin-veined ore deposit mining

A technology for crushing surrounding rocks and control methods, applied in blasting, ground mining, mining equipment, etc., can solve problems such as inability to go up the stope, reduced mining efficiency, cracking and falling off of surrounding rocks, etc., to improve the stability of the stope, reduce the Work efficiency, effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

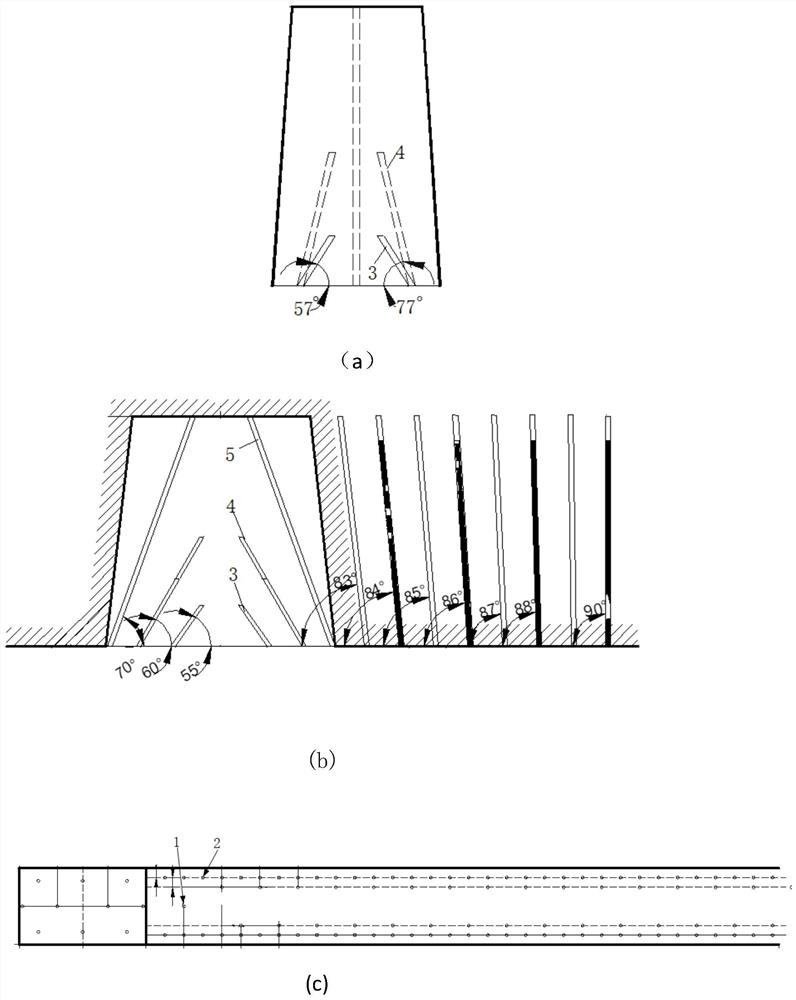

[0083] 1. Double-controlled blasting with layered holes and smooth surfaces

[0084] In order to ensure the integrity and stability of the surrounding rock in the stope, the double-controlled blasting technology with empty holes and smooth surfaces is adopted, and the mining of each layer is advanced from the middle to both sides of the stope. The cutting hole adopts three-stage compound cone cutting, and then drills the main blasting hole and empty holes along the length of the stope. The empty holes are arranged along the boundaries of both sides of the stope (upper and lower rock masses), and the main blasting hole in the middle adopts a Z-shape The layout is as follows:

[0085] (1) Controlled blasting of side holes

[0086] Side hole control blasting hole layout. In order to obtain the blasting free surface, the cutting operation is carried out in the middle of the stope. A total of 10 cutting holes are arranged, and 4 cutting holes (0#, 1#) are arranged in the center, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com