Station hydrogenation and solid hydrogen storage device with high heat exchange characteristic

A technology of hydrogen storage device and thermal characteristics, which is applied in fixed-capacity gas storage tanks, container discharge methods, gas/liquid distribution and storage, etc., can solve the problem of inability to control the reversibility of hydrogen absorption and desorption, and reduce hydrogen storage and hydrogen absorption and hydrogen desorption rate, affecting the output power of hydrogen fuel cells, etc., to achieve the effect of lowering the temperature, increasing the hydrogen absorption and desorption rate, and uniform stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

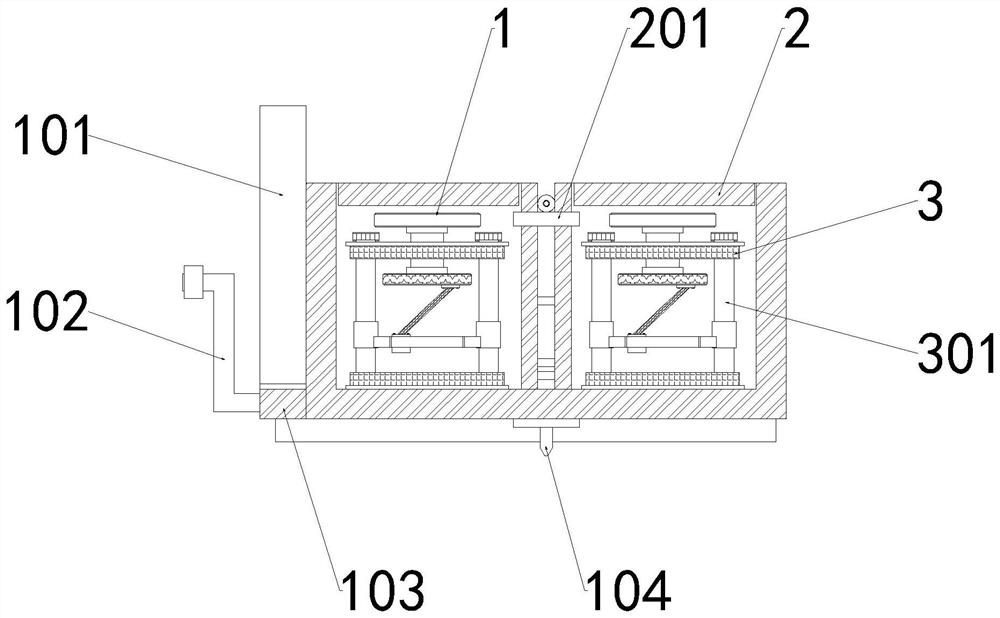

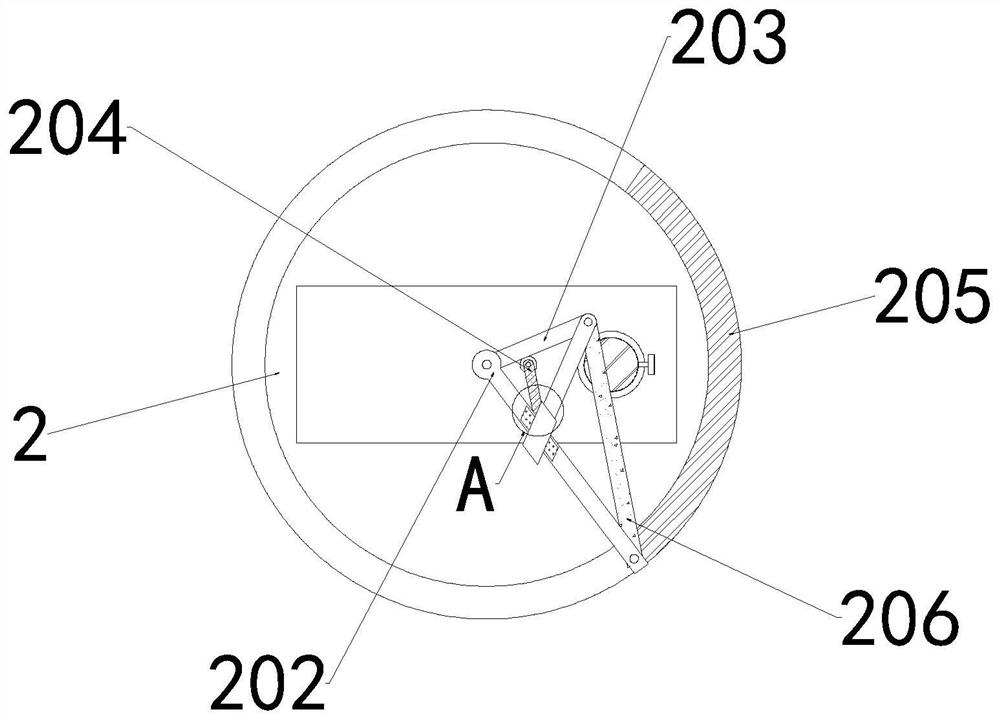

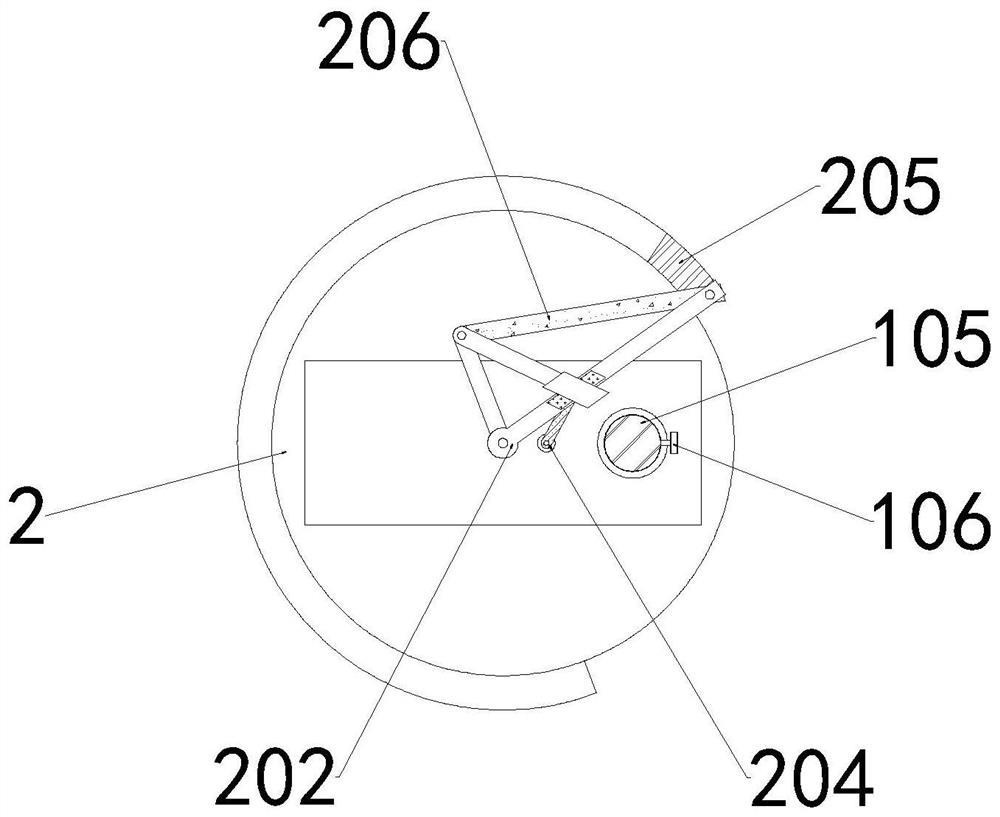

[0027] See Figure 1 to 8 In the embodiment of the present invention, a stationary hydrogen and solid storage device having high heat transfer characteristics, including: the hydrogen storage tank 1, the strut 101, and the hydrogen cover 2, the right end of the hydrogen storage tank 1 is fixedly connected The pillar 101, and the top of the hydrogen storage tank 1 is fitted with at least two hydrogen cover 2, and the inner portion of the hydrogen storage tank 1 and the strut 101 are provided with a hydrogen storage member, and the internal portion of the hydrogen cover 2 is provided with a regulating member. The middle portion of the hydrogen storage tank 1 is set.

[0028] Wherein, the hydrogen storage member includes: the intake port 103 and the fixing plate 3, the intake port 103 is embedded in the inner bottom portion of the strut 101, and the left end of the intake port 103 is fixedly connected to the intake pipe 102, and the intake pipe 102 is entirely In the "S" shape, hydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com