Slab Inclusion Detection Method

A detection method and a technology of inclusions, which are applied in the direction of measuring devices, preparation of test samples, and optical testing of flaws/defects, etc., can solve the problems of low detection efficiency and high detection cost, reduce detection costs, improve accuracy, and eliminate The effect of discontinuity and chance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In the following description, for the purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of one or more embodiments. It will be apparent, however, that the embodiments may be practiced without these specific details.

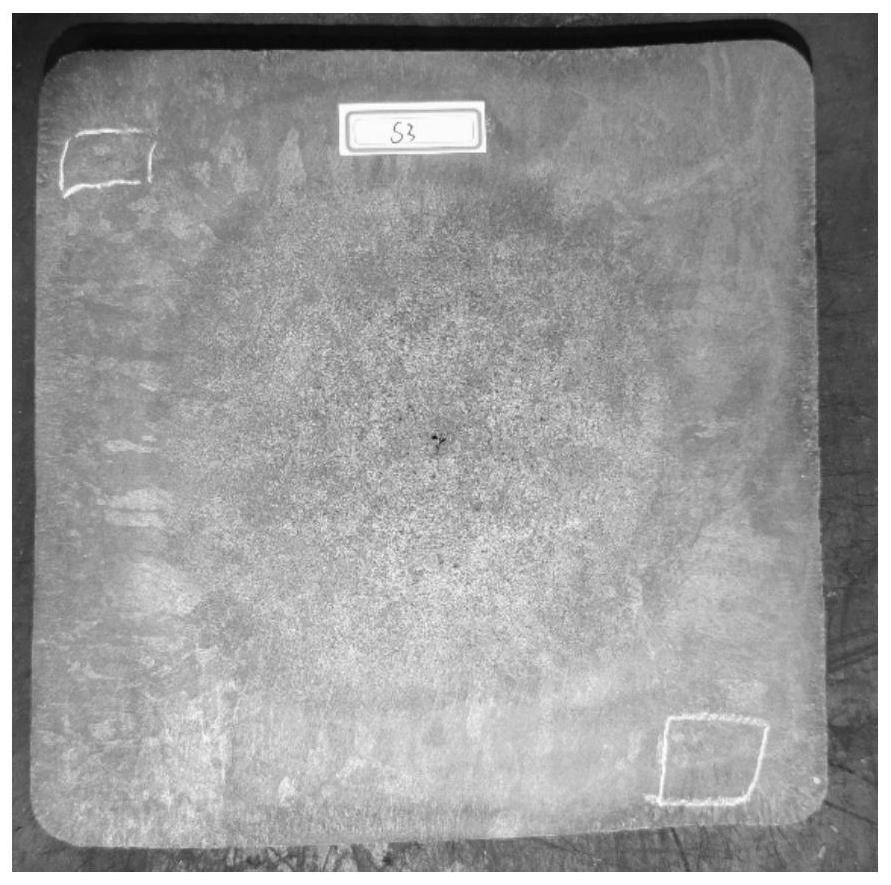

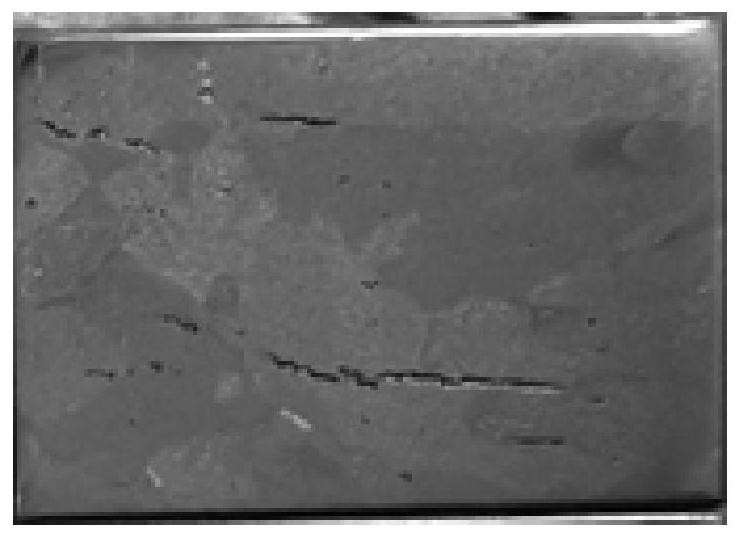

[0032] A method for detecting large inclusions in a slab with low cost and high detection efficiency of the present invention utilizes the principle that once large inclusions exist in the surface area of the slab, cracks will appear when the quenching strength is sufficiently large. Whether there are cracks in the slab after surface quenching is used to determine and analyze whether there are large inclusions in the slab to be tested.

[0033] Various embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

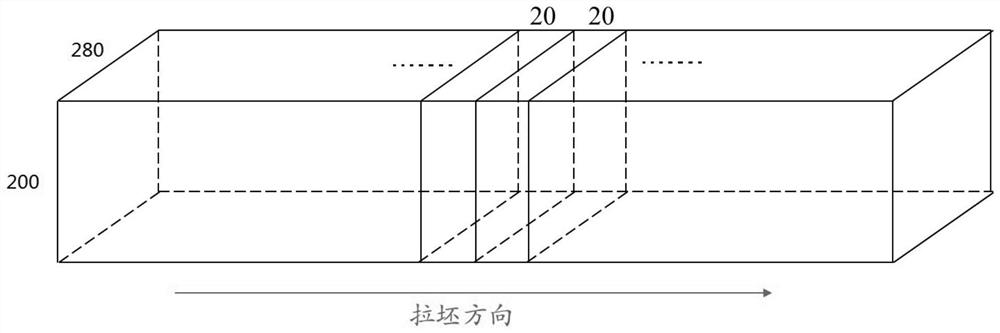

[0034] Figure 1 to Figure 4 An overall description of the method for the detection of inclusions in slabs is given. Specifica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com