Mini LED dodging sheet, preparation process thereof, and backlight module

A preparation process and backlight module technology, which is applied in optics, optical components, nonlinear optics, etc., can solve problems such as poor visual effect, limited light divergence angle, and inability to guarantee, so as to reduce the demand of Mini LED power and improve assembly efficiency and the difficulty of assembly, the effect of reducing power consumption and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

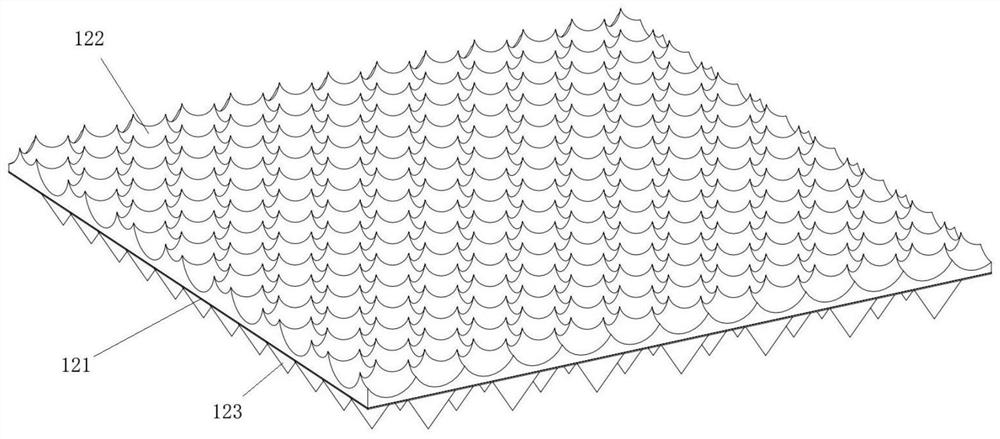

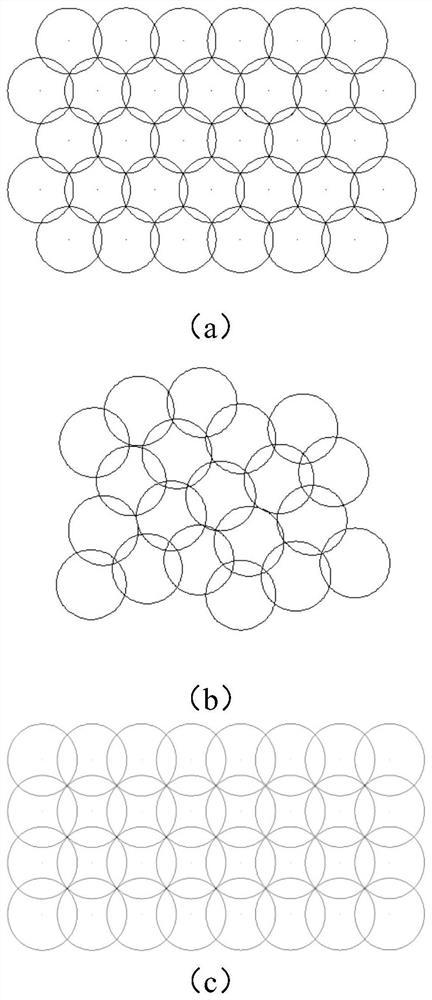

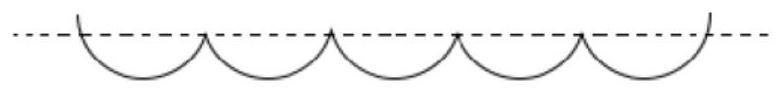

[0049] This embodiment provides a Mini LED dodging sheet, which includes a base 121 , several microlens structures 122 on one side of the base 121 , and a convex mirror structure on the other side of the base 121 . Such as figure 1 As shown, the microlens structure 122 shown in the figure is a circular concave structure 1221 . The concave surface of the microlens structure 122 is preferably a curved surface. Several microlens structures 122 are arranged in multiple rows, and several microlens structures 122 in two adjacent rows are arranged in a staggered manner, such as figure 2 as shown in a, or arranged randomly, such as figure 2 As shown in b, or orthogonal arrangement, such as figure 2 as shown in c. Partial overlap between two adjacent microlens structures 122, such as figure 2 a-2c and image 3 shown. The overlapping range between adjacent microlens structures 122 is 5%-25%, preferably 10%. Adjacent microlens structures 122 are partially overlapped, on the o...

Embodiment 2

[0072] The difference between this embodiment and the first embodiment is that the microlens structure 122 on one side of the dodging sheet in this embodiment is a circular convex structure 1222 . The protruding surface of the microlens structure 122 is preferably a curved surface. Such as Figure 21 to Figure 24 The dodging sheet schematically shown has a raised microlens structure 122 on one side and a conical convex mirror body 123 on the other side. or as Figure 25 and Figure 26 The dodging sheet schematically shown has a raised microlens structure 122 on one side and a quadrangular pyramid-shaped convex lens body 123 on the other side. The preparation method of the dodging sheet and the structure of the backlight module in this embodiment are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com