Method of processing solid polymer particles of a polycondensate by means of a multi-rotation system

A polycondensate, solid technology, applied in the field of processing solid plastic particles, can solve the problems of time and cost consumption, disadvantages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

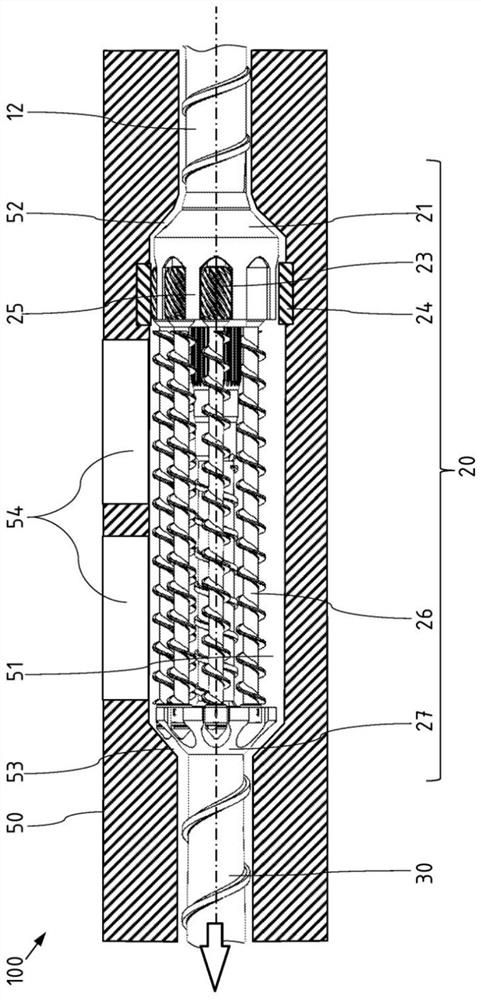

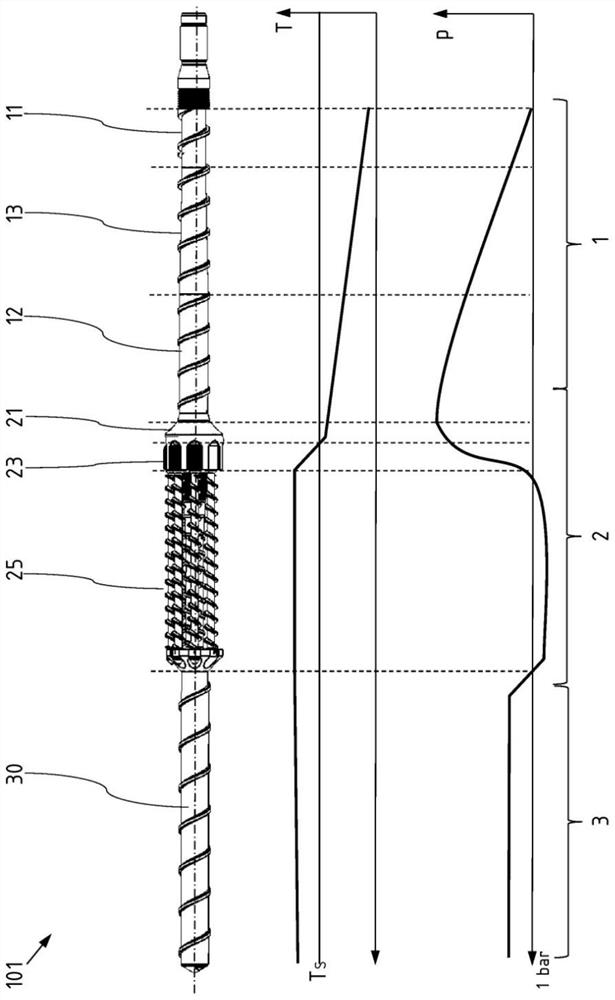

[0032] figure 1 A detail of a multi-rotation system 100 known per se is shown. Arranged in the housing recess 51 of the housing 50 is an extruder screw divided into different regions. The multi-rotation unit 20 is arranged between a metering zone 12 for homogenizing the previously aspirated and at least partially melted plastic particles, and a discharge zone 30 delivering the fully processed plastic melt. This has the following basic characteristics:

[0033] - A transition cone 21 is formed at the transition from the metering zone 12 ; a conical gap 52 is formed towards the housing 50 .

[0034] - The drive zone follows, in which the pinion 23 of the planetary screw 26 runs in a rotating ring 24 which is connected to the housing and has internal teeth 24 . A channel 25 is located between the pinions 23 .

[0035] - The planetary screw 26 rotates on its own, while the whole extruder screw rotates and therefore the rotor mounted in it also rotates. They extend over most o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com