Multilayer film for laser printing, multilayer body for electronic passports, multilayer body for plastic cards, film for plastic cards, plastic card, data sheet for electronic passports, and electronic passport

A technology for multilayer films and plastic cards, which is applied to the fields of multilayer films for laser printing, laminates for electronic passports, laminates for plastic cards, films for plastic cards, plastic cards, data sheets for electronic passports, and electronic passports , can solve the problems of polycarbonate resin deterioration, difficult to use for a long time, etc., and achieve the effect of suppressing equipment pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

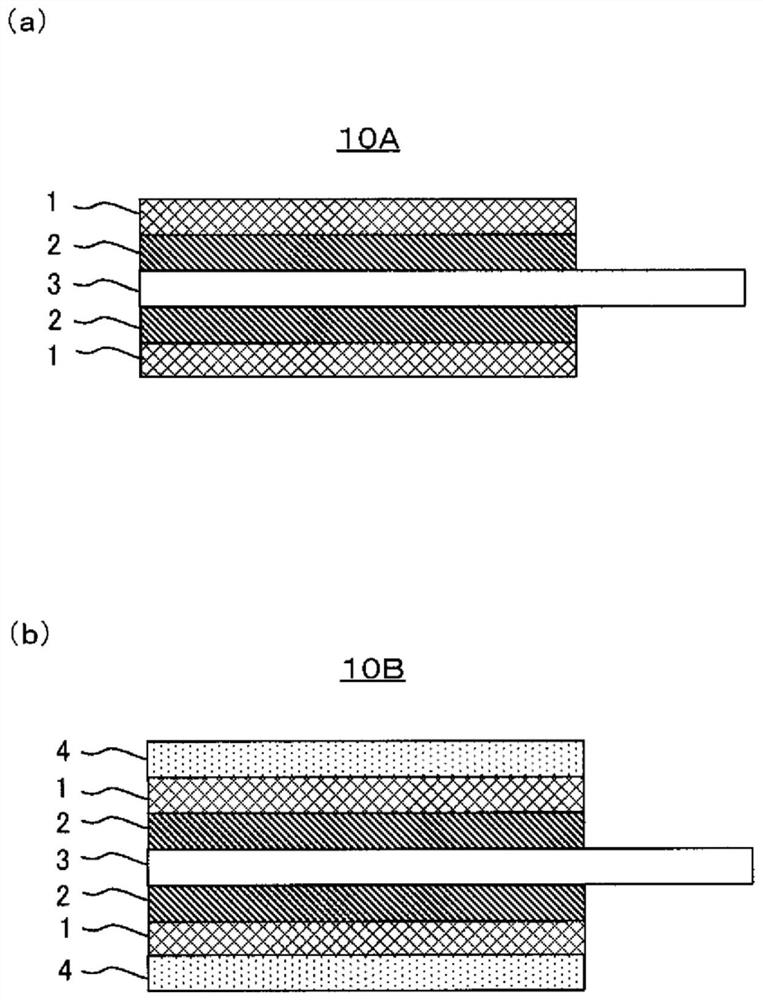

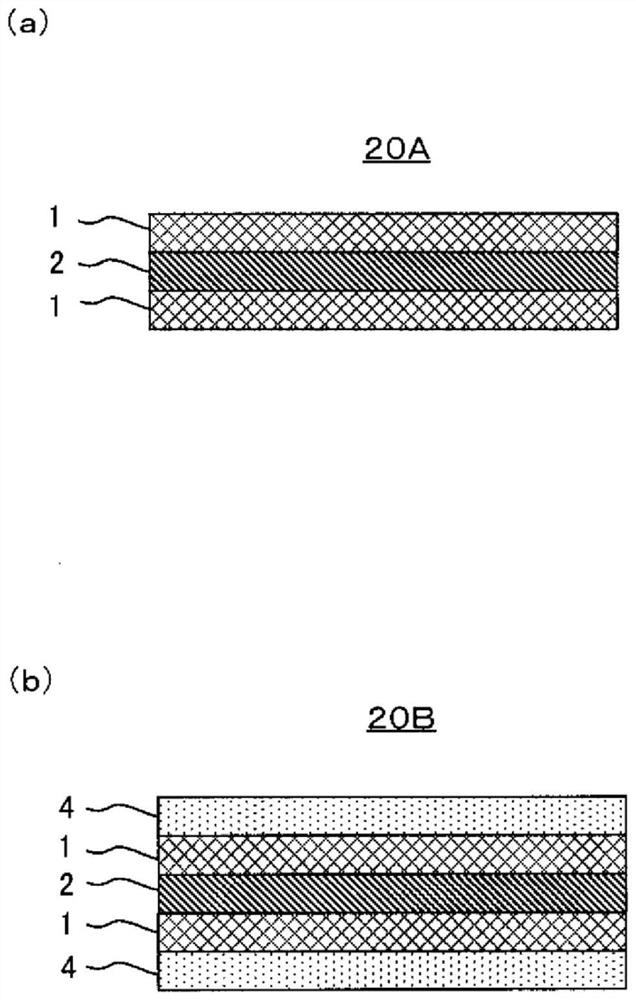

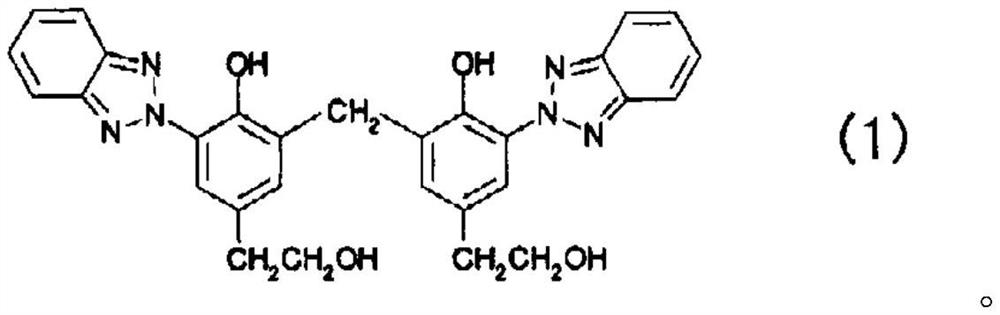

[0165] As layer (X), dry blend (A)-1, (B)-1 and (D)-1 at a mass ratio of 69.955:30:0.045, and use an extruder to produce two types of three-layer multi-manifold The nozzle was extruded at 240° C. as the first layer and the third layer (both outer layers).

[0166] In addition, at the same time as the layer (Y), (A)-1 and (C)-1 were compounded at a mass ratio of 99.75:0.25. For the obtained compound, an extruder was used, and the same nozzle was used as the second layer. 2 layers (middle layer) were extruded at 240°C. In addition, at this time, the discharge amount of the molten resin was adjusted so that the thickness of each layer was 8 / 34 / 8 (μm) for the first layer / second layer / third layer. Next, the coextruded sheet was quenched with a casting roll at about 120° C. to obtain a multilayer film. Table 1 shows the evaluation results of the obtained multilayer film.

Embodiment 2

[0168] In Example 1, the mixing mass ratio of (A)-1, (B)-1 and (D)-1 of the first layer and the third layer was 93.955:6:0.045, and in addition, the same as in Example 1 A multilayer film was fabricated and evaluated in the same manner. The results are shown in Table 1.

Embodiment 3

[0170] In Example 1, the mixing mass ratio of (A)-1, (B)-1, and (D)-1 of the first layer and the third layer was 96.955:3:0.045, and in addition, the same as in Example 1 A multilayer film was fabricated and evaluated in the same manner. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com