Constant-pressure full-automatic multi-medium filtering device

A multi-media filtration and fully automatic technology, applied in the direction of filtration separation, filtration circuit, separation method, etc., can solve the problems of cumbersome installation, single-point debugging of control system, high coupling, etc., and achieve the effect of high degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

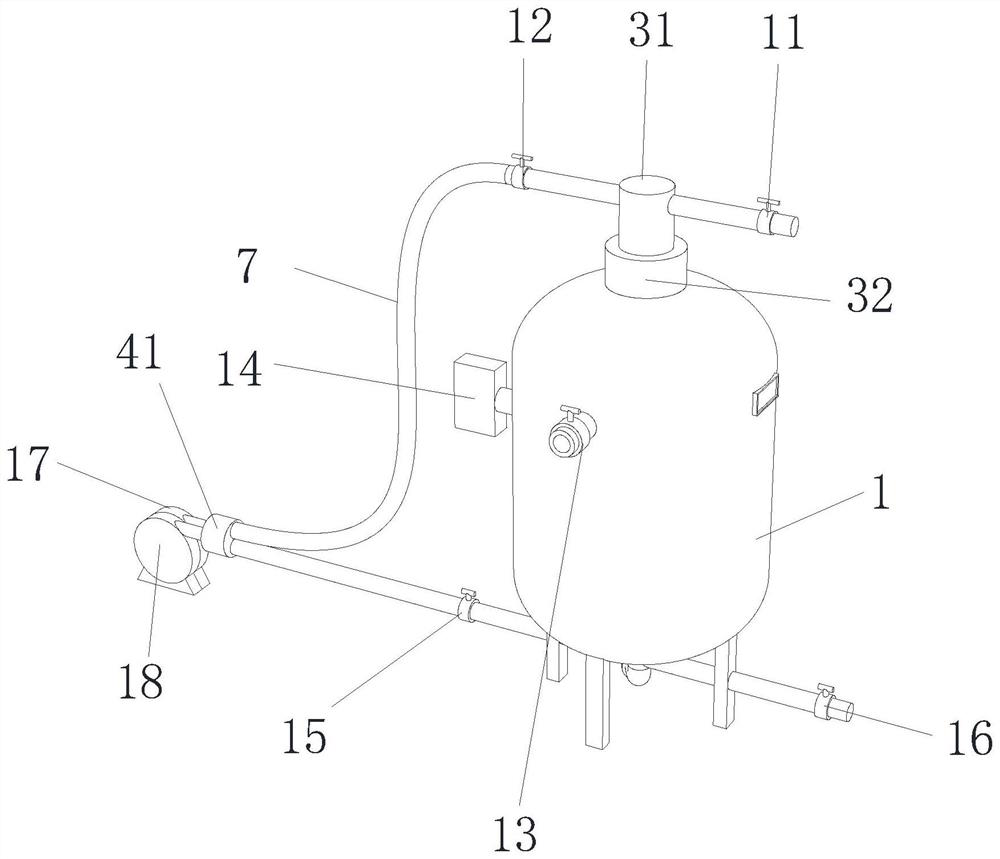

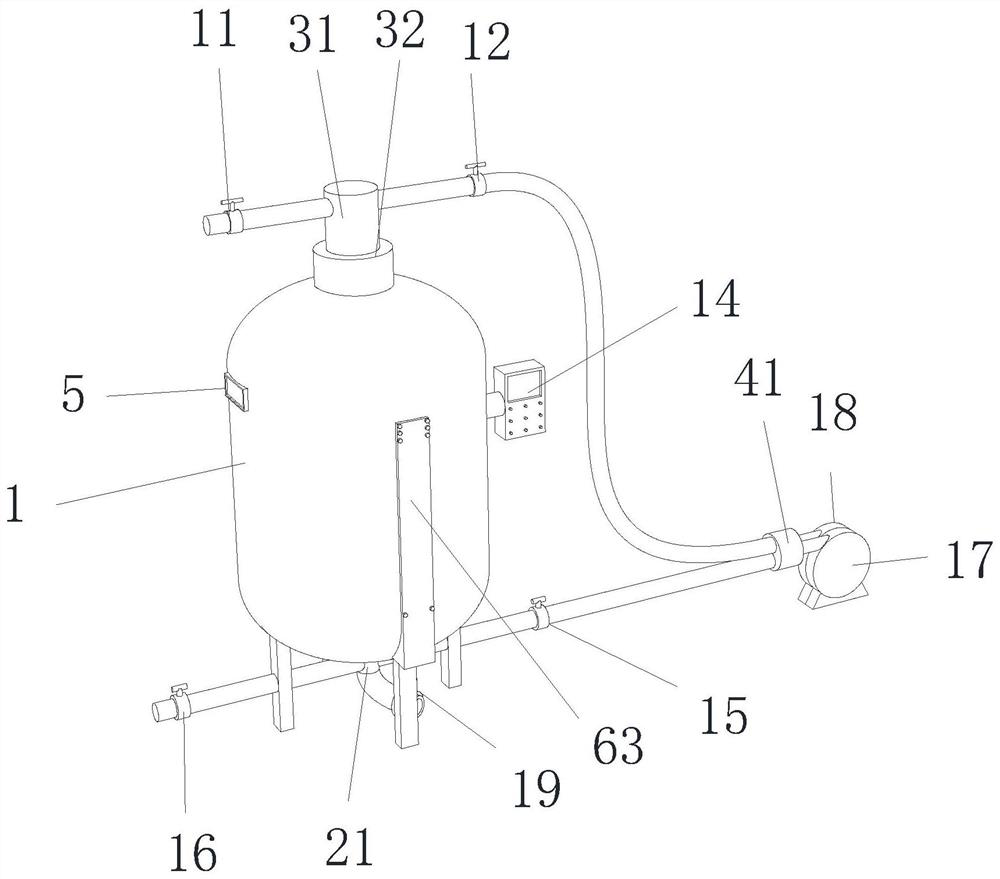

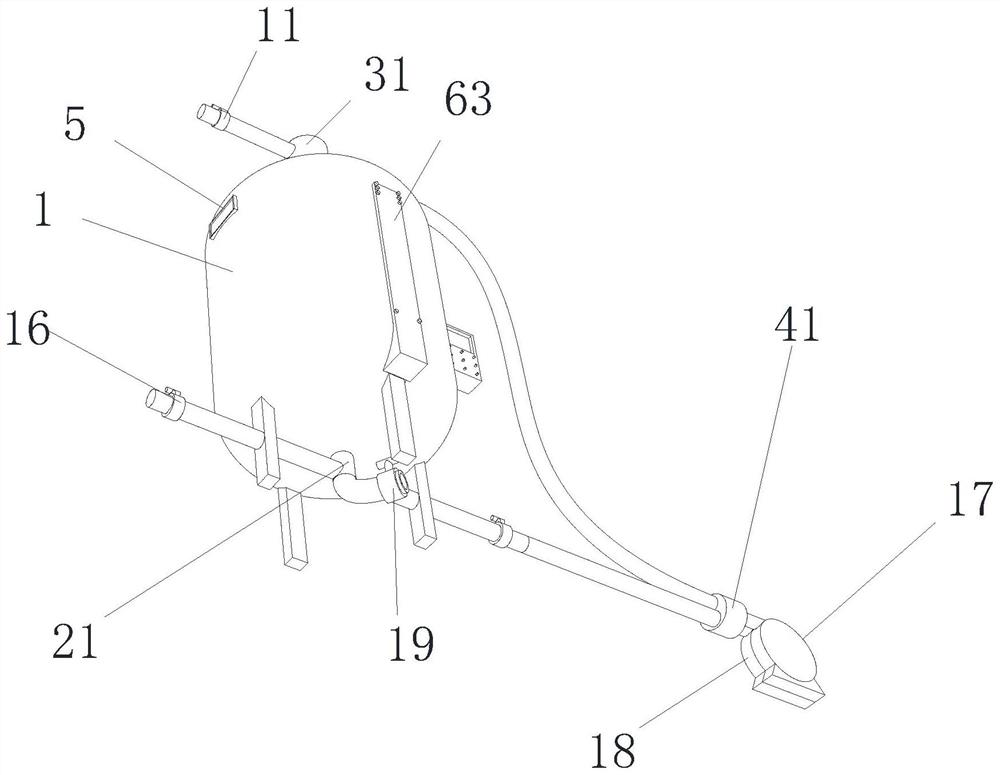

[0032] Example 1: See figure 1 , figure 2 , image 3 , Figure 9 with Figure 10, a constant pressure full-automatic multi-media filter device, comprising a filter body 10 and a conduit 7, the outer peripheral surface of the filter body 10 is provided with a regulating device, the regulating device includes a console 14, and the console 14 is fixedly mounted on the filter body 10 on the left side of the circumference outer surface, the front of the filter body 10 is fixedly installed with an exhaust valve 13 through the conduit 7, the upper surface of the filter body 10 is provided with a joint 31, and the right side of the joint 31 is fixedly installed with a backwash drainage through the conduit 7 The water inlet valve 12 is fixedly installed on the left side of the valve 11 and the joint 31 through the conduit 7; the backwash water inlet is provided at the lower part of the filter body 10, and the T-shaped joint 21 is fixedly installed with the filter body 10 and the T-...

Embodiment 2

[0034] Example 2: See image 3 , on the basis of Embodiment 1, the filter body 10 is provided with a filter mechanism for filtering waste water, the filter mechanism includes a smokeless butterfly layer 51, and the smokeless butterfly layer 51 is arranged in the filter body 10, and the smokeless butterfly layer 51 A fine sand layer 52 is provided below, a coarse sand layer 53 is arranged below the fine sand layer 52, a support layer 54 is provided under the coarse sand layer 53, and a filter member 55 is arranged below the support layer 54 in the sand, and the fine sand Layer 52, coarse sand layer 53, sand lining support layer 54 and filter element 55 are all arranged in the filter body 10

[0035] When in use, the smokeless butterfly layer 51 can initially filter the water, effectively prevent the flow of water from driving the internal filter medium to move, and prevent the occurrence of confusion. The fine sand layer 52 can block and filter larger particles in the water, T...

Embodiment 3

[0036] Example 3: See image 3 with Figure 4 , on the basis of the second embodiment, the filter body 10 is provided with an auxiliary mechanism to speed up the filtration, the auxiliary mechanism includes an oil cylinder 32, the oil cylinder 32 is fixedly installed on the upper surface of the filter body 10, and the lower surface of the oil cylinder 32 is movably installed with Telescopic rod 33, the following of telescopic rod 33 is fixedly installed with extruding plate 34, and the upper surface of oil cylinder 32 offers circular groove one 36, and the inner wall bottom surface of circular groove one 36 offers circular groove two 37, and the upper surface of oil cylinder 32 The surface is fixedly installed with joint 31 by circular groove one 36, and water guide pipe 35 is fixedly installed below joint 31, and water guide pipe 35 is movably installed in circular groove two 37, and water guide pipe 35 runs through movable expansion rod 33 successively, extrudes Press plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com