Holographic hot stamping film with glaze color jade porcelain effect and preparation method

A hot stamping film and holographic technology, applied in the field of anti-counterfeiting, can solve the problems of poor wear resistance of soft resin, easy to wear, and single holographic color layer structure, so as to increase wear resistance and high temperature resistance, good wear resistance, The effect of enhancing oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

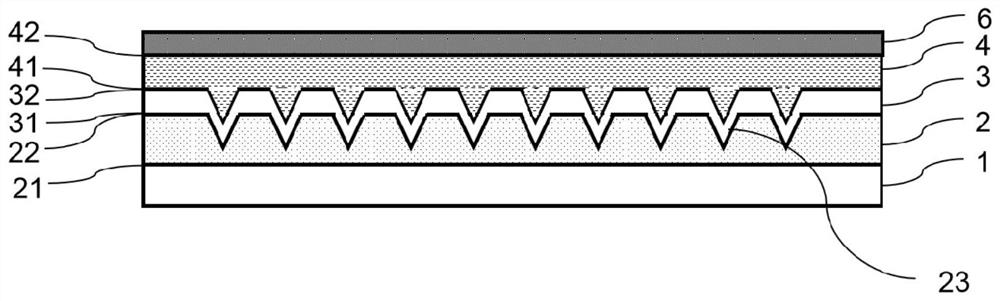

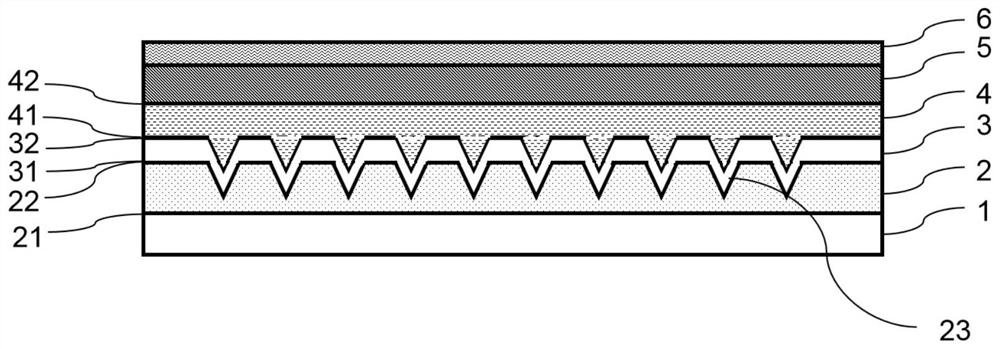

[0062] The present invention also provides a figure 1 Shown, based on the preparation method of the above-mentioned holographic hot stamping film with glazed jade porcelain effect; comprising:

[0063] S1: Coating ultraviolet paint on the upper surface 12 of the substrate layer 1, performing molding and ultraviolet curing to obtain a UV cured layer 2 with a holographic micro-groove structure 23 on the upper surface; wherein, the depth of the holographic micro-groove structure 23 is 3-5 μm ;

[0064] S2: coating the upper surface 22 of the UV curable layer 2 to form a holographic glaze layer 3 with a thickness of 1-2 μm;

[0065] S3: Coating the upper surface 32 of the holographic glaze layer 3 to form a jade porcelain color layer 4 with a thickness of 2-3 μm;

[0066] S4: Coating the upper surface 42 of the jade porcelain color layer 4 to form a glue layer 6;

[0067] Among them, the upper and lower surfaces of the holographic glaze layer 3 are copied with a holographic mic...

Embodiment 1

[0076]Set the mass percentage of each component raw material in the holographic glaze layer 3 as follows: methacrylic resin: 75%, aldehyde and ketone resin: 20%, fluorescent dye: 5%;

[0077] When making, put the methacrylic resin, aldehyde and ketone resin, and fluorescent dyes of the set components in the container, add methyl ethyl ketone to dilute it into a paint with a solid content of 20%, stir it evenly, and use a coater to roll coat and dry The holographic glaze color layer 3 is prepared on the basis of the UV curable layer in the same way.

[0078] Set the mass percent of each component raw material in the jade porcelain color layer 4 to be: hydroxyl acrylic resin: 60%, diisocyanate: 10%, titanium dioxide filler: 30%;

[0079] When making, put the hydroxy acrylic resin, diisocyanate and titanium dioxide filler of the set components in the container, add methyl ethyl ketone to dilute it to form a coating with a solid content of 25%, stir it evenly, and use a coating ma...

Embodiment 2

[0081] Set the mass percentage of each component raw material in the holographic glaze layer 3 as follows: methacrylic resin: 85%, aldehyde and ketone resin: 10%, red metal complex dye: 5%;

[0082] When making it, put the methacrylic resin, aldehyde and ketone resin, and red metal complex dyes of the set components in the container, add methyl ethyl ketone to dilute it into a coating with a solid content of 20%, stir it evenly, and use a coater roller The holographic glaze layer 3 is prepared on the basis of the UV curable layer by coating and drying.

[0083] Set the mass percent of each component raw material in the jade porcelain color layer 4 to be: hydroxyl acrylic resin: 60%, diisocyanate: 20%, silicon powder filler: 20%;

[0084] When making, put the hydroxy acrylic resin, diisocyanate, and silicon powder filler of the set components in the container, add butanone to dilute it into a coating with a solid content of 25%, stir it evenly, and use a coating machine to roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com