Preparation and Application of a Biocompatibility Coating for Improving the Surface of Medical Zinc/Zinc Alloy

A biocompatible, zinc alloy technology, applied in metal material coating technology, coating, medical science and other directions, can solve the problem of poor osteogenic performance and the explosive release of harmful ions, etc., to meet clinical needs, the process is simple, good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

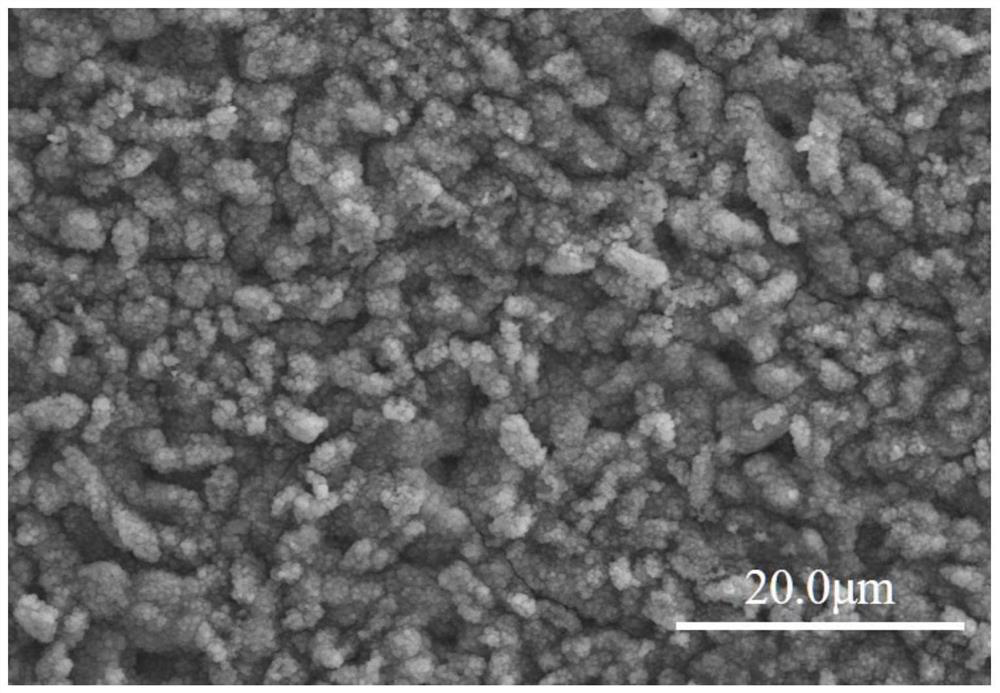

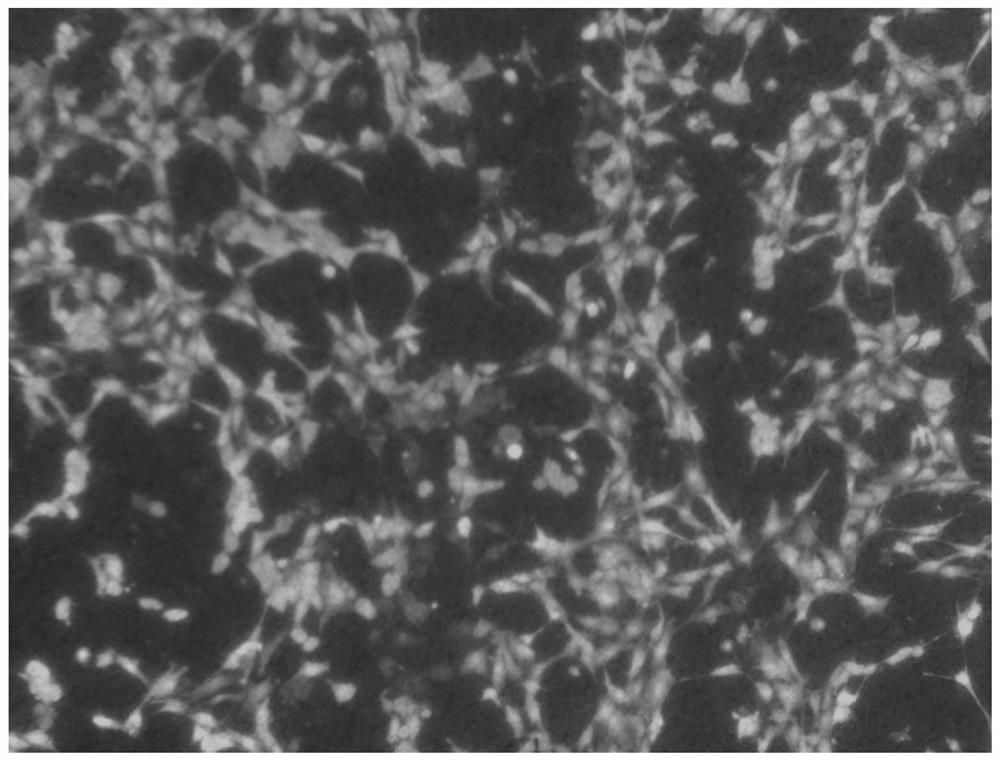

[0035]Prepare a silicon-doped bioactive calcium-phosphorus coating on the surface of the Zn-Mg alloy. The Zn-Mg alloy rod is made into a Ф10×2mm sample by wire cutting. Grinding with silicon carbide sandpaper, followed by ultrasonic cleaning with acetone, alcohol and deionized water for 10 minutes to remove impurities and oil stains on the surface, and air drying at room temperature for later use. Prepare a zinc phosphate solution with a concentration of 0.05mol / L zinc nitrate and 0.2mol / L phosphoric acid, adjust the pH of the obtained conversion solution to 3 with NaOH, and soak the cleaned zinc alloy in the zinc phosphate conversion solution for 1 hour at room temperature Then take it out and wash it with pure water and blow dry. Then, configure 0.5mol / L calcium chloride and 0.001mol / L sodium silicate solution, put the pretreated sample into the solution, take it out after 8 hours in a constant temperature water bath at 90°C, rinse it with pure water, and dry it to get Zn -...

Embodiment 2

[0037] A strontium-doped bioactive calcium-phosphorus coating was prepared on the surface of the Zn-Sr alloy. After the sample was polished, it was ultrasonically cleaned with acetone, alcohol, and deionized water for 10 minutes to remove impurities and oil on the surface, and air-dried at room temperature for later use. Prepare a zinc phosphate solution with a concentration of 0.07mol / L zinc nitrate and 0.15mol / L phosphoric acid, and use NaOH to adjust the pH of the obtained conversion solution to 2.5, and soak the cleaned zinc alloy in the zinc phosphate conversion solution for 1 hour at room temperature Then take it out and wash it with pure water and blow dry. Then, configure 0.5mol / L calcium chloride and 0.005mol / L strontium nitrate solution, put the pretreated sample into the solution, take it out after 4 hours in a constant temperature water bath at 90°C, rinse it with pure water, and then dry it to get Zn- Strontium-doped bioactive calcium-phosphorus coating prepared o...

Embodiment 3

[0039] A copper-doped bioactive calcium-phosphorus coating was prepared on the surface of the Zn alloy. After the sample was polished, it was ultrasonically cleaned with acetone, alcohol, and deionized water for 10 minutes to remove impurities and oil on the surface, and air-dried at room temperature for later use. Prepare a zinc phosphate solution with a concentration of 0.10mol / L zinc nitrate and 0.25mol / L phosphoric acid, and use NaOH to adjust the pH of the obtained conversion solution to 2, and soak the cleaned zinc alloy in the zinc phosphate conversion solution for 50 minutes at room temperature Then take it out and wash it with pure water and blow dry. Then, configure 0.4mol / L calcium chloride and 0.4mol / L copper chloride solution, put the pretreated sample into the solution, take it out after 10 hours in a constant temperature water bath at 80°C, rinse it with pure water, and dry it to obtain Zn -Copper-doped bioactive calcium-phosphorus coating prepared on Li alloy s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com