A magnesium phosphate bone cement

A magnesium phosphate bone cement and phosphate technology, which is applied in the direction of surgery, tissue regeneration, surgical adhesives, etc., can solve the problems of normal healing speed of backward fractures, adverse effects on tissue healing, and obstacles to fracture healing, so as to facilitate cell crawling, Effects of promoting cell adhesion and reducing toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0042] The magnesium oxide described in the present invention is obtained by calcination of magnesium hydroxide and / or basic magnesium carbonate. In the calcination process, the calcination temperature is 1200°C-1600°C, and the calcination time is 1-6 hours. Preferably, the calcination temperature The temperature is 1400°C-1500°C, and the calcination time is 3-4 hours. Different calcination processes affect the activity of magnesium oxide, and then affect the strength and setting time of bone cement.

[0043] Exemplary formulations of bone cements of the present invention are as follows:

[0044] Recipe a:

[0045] Prepare powder by following weight percentage (wt%):

[0046]

[0047] The liquid preparation is deionized water, and the liquid-solid...

PUM

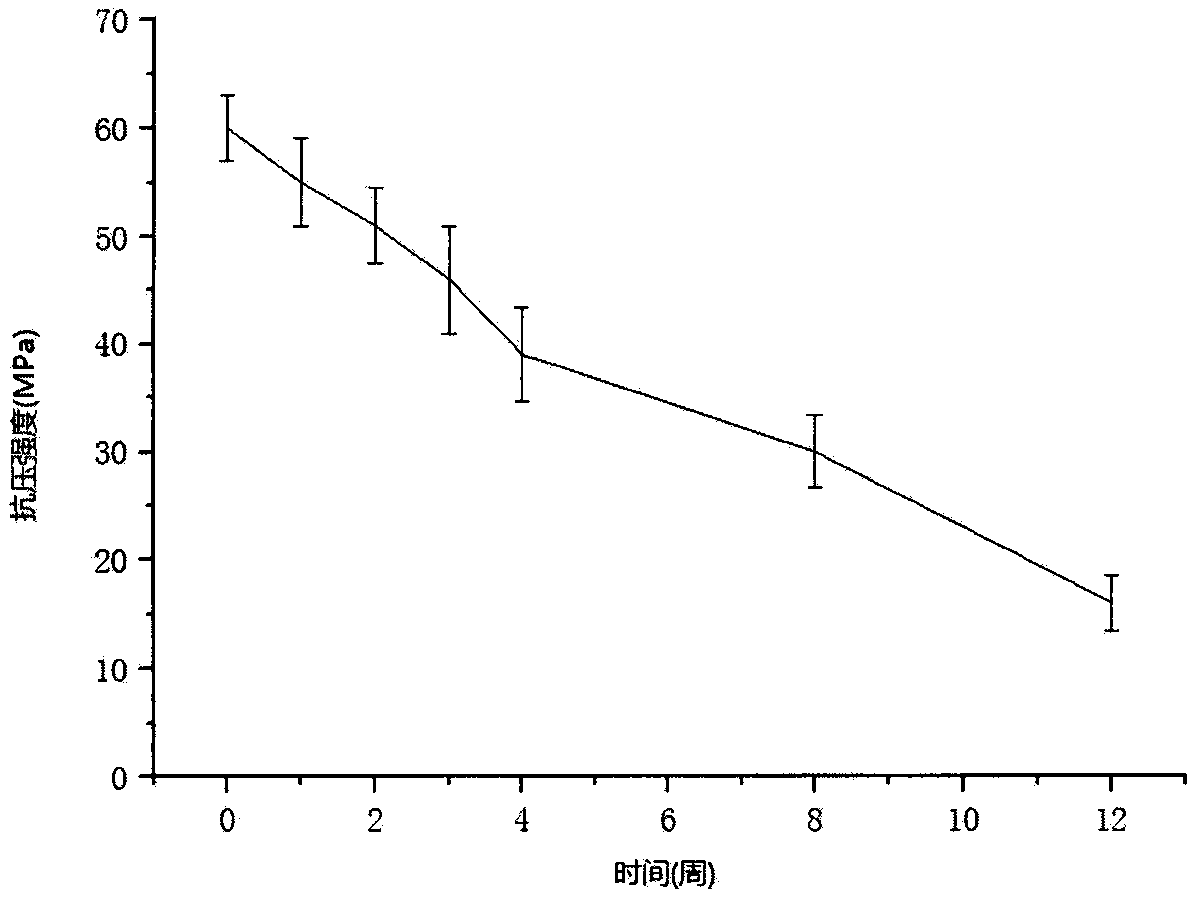

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com