Multi-ion co-doped tetracalcium phosphate powder, synthetic method and application

A technology of tetracalcium phosphate powder and tetracalcium phosphate, which is applied in the direction of phosphorus compounds, chemical instruments and methods, prostheses, etc., and can solve the problems of unfavorable bone cell proliferation and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

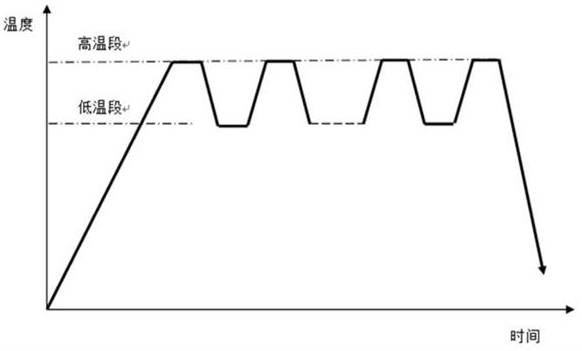

Method used

Image

Examples

Embodiment 1

[0053] Example 1Ca 3.2 Sr 0.5 Mg 0.2 Zn 0.1 (PO 4 ) 1.9 (SiO 4 ) 0.1 O powder

[0054] Weigh 5.631gCa(OH) 2 , 2.214gSrCO 3 , 0.890gMg(NO 3 ) 2 and 0.892gZn(NO 3 ) 2 ·6H 2 O was dissolved in 100ml of deionized water to prepare a multi-ion mixed solution L1, and 30ml of concentrated ammonia water was added to control the pH at about 8, and stirred in a water bath at 40°C for 30min; take 5.586gH 3 PO 4 and 0.552gNa 4 SiO 4 Dissolved in 50ml of deionized water to prepare phosphorus-containing and silicate mixed solution L2; under 25kHz, 500W ultrasonic assisted conditions, the L2 solution was added dropwise to the L1 solution at a rate of 2.5ml / min, and mixed and stirred for 2 hours to obtain Multi-ion co-doped hydroxyapatite Ca 7.6 Sr 1.5 Mg 0.6 Zn 0.3 (PO 4 ) 5.7 (SiO 4 ) 0.3 (OH) 2 Suspension L3. Then, weigh 4.723g Ca (NO 3 ) 2

[0055] 4H 2 O and 2.12gNa 2 CO 3 , add 20ml of deionized water to make a solution, and under the condition of 25kHz, ...

Embodiment 2

[0061] Example 2Ca 3.3 Sr 0.2 mn 0.2 co 0.2 Cu 0.1 (PO 4 ) 1.8 (SiO 4 ) 0.2 O powder

[0062] Weigh 5.854gCa(OH) 2 , 0.886gSrCO 3 , 1.074gMn(NO 3 ) 2 , 0.563gCu(NO 3 ) 2 and 1.746gCo(NO 3 ) 2 ·

[0063] 6H 2Dissolve O in 100ml of deionized water to prepare a multi-ion mixed solution L1, add 30ml of concentrated ammonia water, control the pH at about 8, and stir in a water bath at 60°C for 30min. Take 5.292gH 3 PO 4 and 0.732gNa 2 SiO 3 Dissolved in 46ml of deionized water to form a mixed solution of phosphorus and silicate ions L2, under 25kHz, 500W ultrasonic assisted conditions, the L2 solution was added dropwise to the L1 solution at a rate of 4ml / min, and mixed and stirred for 3.5 hours to obtain poly Ionic co-doped hydroxyapatite Ca 7.9

[0064] Sr 0.6 mn 0.6 co 0.6 Cu 0.3 (PO 4 ) 5.4 (SiO 4 ) 0.6 (OH) 2 Suspension L3. Weigh 4.723gCa(NO 3 ) 2 4H 2 O and 1.680 g NaHCO 3 , adding 20ml of deionized water to form a solution, and under the...

Embodiment 3

[0068] Example 3Ca 2.8 Mg 0.5 Fe 0.3 co 0.2 Cu 0.1 Zn 0.1 (PO 4 ) 1.7 (SiO 4 ) 0.3 O powder

[0069] Weigh 4.742gCa(OH) 2 , 2.225gMg(NO 3 ) 2 , 1.619gFe(NO 3 ) 3 , 0.892gZn (NO 3 ) 2 ·6H 2 O, 1.746gCo(NO 3 ) 2 ·6H 2 O and 0.563gCu(NO 3 ) 2 Dissolve in 100ml of deionized water to make a multi-ion mixed solution L1, add 30ml of concentrated ammonia water, control the pH value to 7~8, stir in a 50°C water bath for 30min. Take 4.998gH 3 PO 4 and 1.099gNa 2 SiO 3 Dissolved in 48ml of deionized water to form a mixed solution L2 containing phosphorus and silicon ions. Under 25kHz, 500W ultrasonic assisted conditions, the L2 solution was added dropwise to the L1 solution at a rate of 3ml / min, and mixed and stirred for 4 hours to obtain multiple Ionic co-doped hydroxyapatite Ca 6.4 Mg 1.5 Fe 0.9 co 0.6 Cu 0.3 Zn 0.3 (PO 4 ) 5.1 (SiO 4 ) 0.9 (OH) 2 Suspension L3. Weigh 3.1634gCa(CH 3 COO) 2 and 1.92g (NH 4 ) 2 CO 3 , add 30ml of deionized water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com