Method for controlling pH (potential of hydrogen) of ammonium sulphate solution prepared by phosphogypsum

A control method, gypsum technology, applied in the direction of ammonium sulfate, etc., can solve the problem of high pH value of the solution, and achieve the effect of improving product quality, reducing cost, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

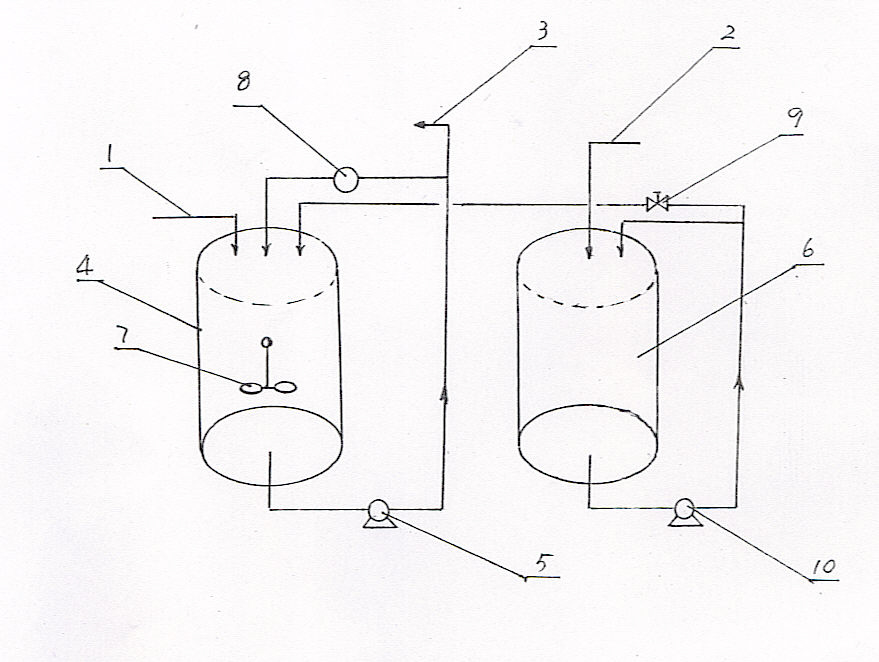

[0014] Accompanying drawing has schematically illustrated flow process technology of the present invention, and certain limited liability company phosphate fertilizer factory adopts the control method of a kind of phosphogypsum system ammonium sulfate solution pH of the present invention: put a neutralization tank 4, phosphoric acid storage tank 6 behind the ammonium sulfate solution storage tank And pump, phosphoric acid is added in the phosphoric acid storage tank 6 from phosphoric acid inlet 2, and the phosphoric acid in the phosphoric acid storage tank 6 is pumped into the neutralization tank 4 through the valve 9 through the pump 10, and reacts with the ammonium sulfate solution that enters the neutralization tank 4 from the solution inlet 1, There is a neutralization agitator 7 in the neutralization tank 4 to speed up the reaction by stirring, the pH value of the solution after the reaction is detected by the pH detector 8 on the bypass circulation pipe of the neutralizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com