A kind of bleaching method of waste paper pulp

A technology for deinking pulp and pulp of waste paper, applied in pulp bleaching, adding inorganic compounds, secondary cellulose fibers, etc. Paper fiber loses papermaking ability and other problems, and achieves the effect of reducing consumption, reducing invalid decomposition and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

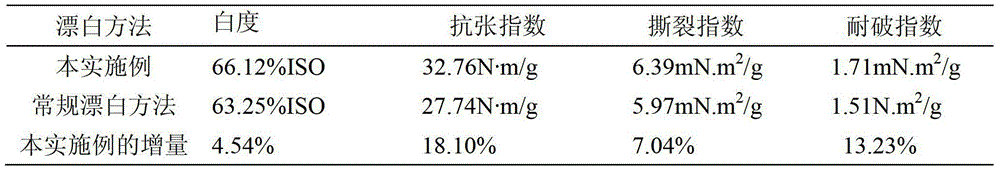

Embodiment 1

[0028] In this embodiment, after the waste newsprint (ONP) is deinked by alkali, the whiteness is 55.2%ISO, and the following steps are adopted to carry out the bleaching method:

[0029] (1) Add H to waste paper deinking pulp 2 SO 4 and NaHSO 3After acidifying pretreatment, directly add diethyltriaminepentaacetic acid (DTPA) without washing to carry out chelation pretreatment;

[0030] Adding H to the waste paper deinking pulp 2 SO 4 and NaHSO 3 Carry out acidification pretreatment, specifically:

[0031] Control slurry concentration is 5wt%, H 2 SO 4 The dosage is 1.5wt% of the dry pulp of waste paper deinking pulp, NaHSO 3 The dosage is 1%, the pretreatment temperature is 65°C, and the pretreatment time is 15min;

[0032] The chelation pretreatment is specifically:

[0033] The pulp concentration was controlled at 5wt%, the amount of diethyltriaminepentaacetic acid (DTPA) was 0.5wt% of the dry pulp of waste paper deinked pulp, the pretreatment temperature was 65°C...

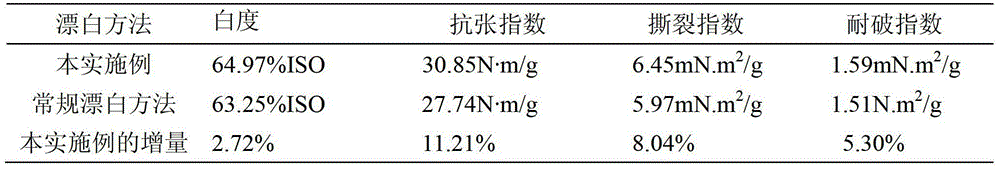

Embodiment 2

[0043] In this embodiment, after the waste newsprint (ONP) is deinked by alkali, the whiteness is 55.2%ISO, and the following steps are adopted to carry out the bleaching method:

[0044] (1) Add H to waste paper deinking pulp 2 SO 4 and NaHSO 3 After acidifying pretreatment, directly add diethyltriaminepentaacetic acid (DTPA) without washing to carry out chelation pretreatment;

[0045] Adding H to the waste paper deinking pulp 2 SO 4 and NaHSO 3 Carry out acidification pretreatment, specifically:

[0046] Control slurry concentration is 8wt%, H 2 SO 4 The dosage is 2.0wt% of the dry pulp of waste paper deinking pulp, NaHSO 3 The dosage is 1.5%, the pretreatment temperature is 75°C, and the pretreatment time is 25min;

[0047] The chelation pretreatment is specifically:

[0048] The pulp concentration was controlled at 8wt%, the amount of diethyltriaminepentaacetic acid (DTPA) was 0.7wt% of the dry pulp of waste paper deinked pulp, the pretreatment temperature was 7...

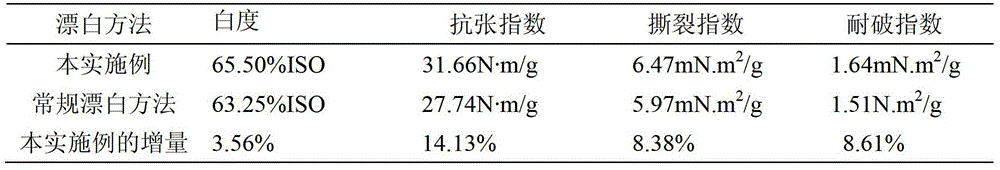

Embodiment 3

[0058] In this embodiment, after the waste newsprint (ONP) is deinked by alkali, the whiteness is 55.2%ISO, and the following steps are adopted to carry out the bleaching method:

[0059] (1) Add H to waste paper deinking pulp 2 SO 4 and NaHSO 3 After acidifying pretreatment, directly add diethyltriaminepentaacetic acid (DTPA) without washing to carry out chelation pretreatment;

[0060] Adding H to the waste paper deinking pulp 2 SO 4 and NaHSO 3 Carry out acidification pretreatment, specifically:

[0061] Control slurry concentration is 5wt%, H 2 SO 4 The dosage is 2.0wt% of the dry pulp of waste paper deinking pulp, NaHSO 3 The dosage is 1%, the pretreatment temperature is 70°C, and the pretreatment time is 20min;

[0062] The chelation pretreatment is specifically:

[0063] The pulp concentration was controlled at 5wt%, the amount of diethyltriaminepentaacetic acid (DTPA) was 0.6wt% of the dry pulp of waste paper deinked pulp, the pretreatment temperature was 70°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com