A deep-sea environment simulation device suitable for testing material corrosion behavior

A deep-sea environment and simulation device technology, applied in the direction of measuring devices, analysis materials, weather resistance/light resistance/corrosion resistance, etc., can solve problems that have not been reported in the report, and achieve the effect of real-time monitoring of environmental parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

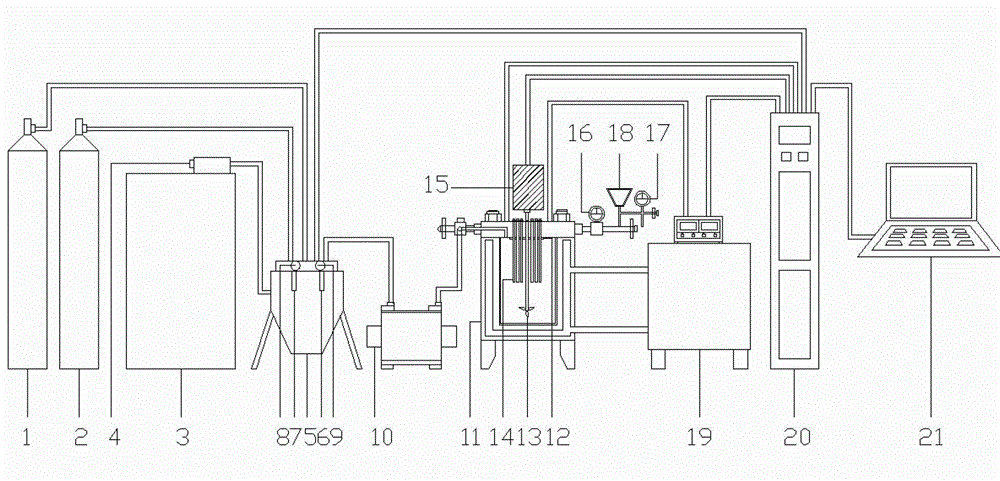

[0020] combine figure 1 , store artificial seawater in the water tank 3 and control the water pump automatic control switch 9 through the water level sensor 7 to make the water pump 4 inject artificial seawater into the liquid replenishment tank 5 in time. Oxygen sensor 6 controls oxygen and nitrogen automatic control switch 8 to make nitrogen and oxygen pass into the liquid replenishment tank to reach the required dissolved oxygen concentration; The artificial seawater meeting the requirement of dissolved oxygen content is injected into the cavity of autoclave 11, and a stepless variable speed motor 15 is installed on the top cover of autoclave 11, and the propeller 13 connected to it goes deep into the cavity of the autoclave to provide the required flow rate for the artificial seawater A composite sensor 12 is placed at the bottom of the top cover of the autoclave 11 to detect environmental parameters such as the temperature, hydrostatic pressure, dissolved oxygen content, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com