In-situ generated hydrogen peroxide and ferrate coupled water treatment advanced purification device and treatment method

A deep purification device, ferrate technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the limited effect of organic matter removal, high storage and transportation costs, pollution Incomplete removal of pollutants and other problems, to achieve excellent purification effect, efficient use of oxygen, and inhibition of side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

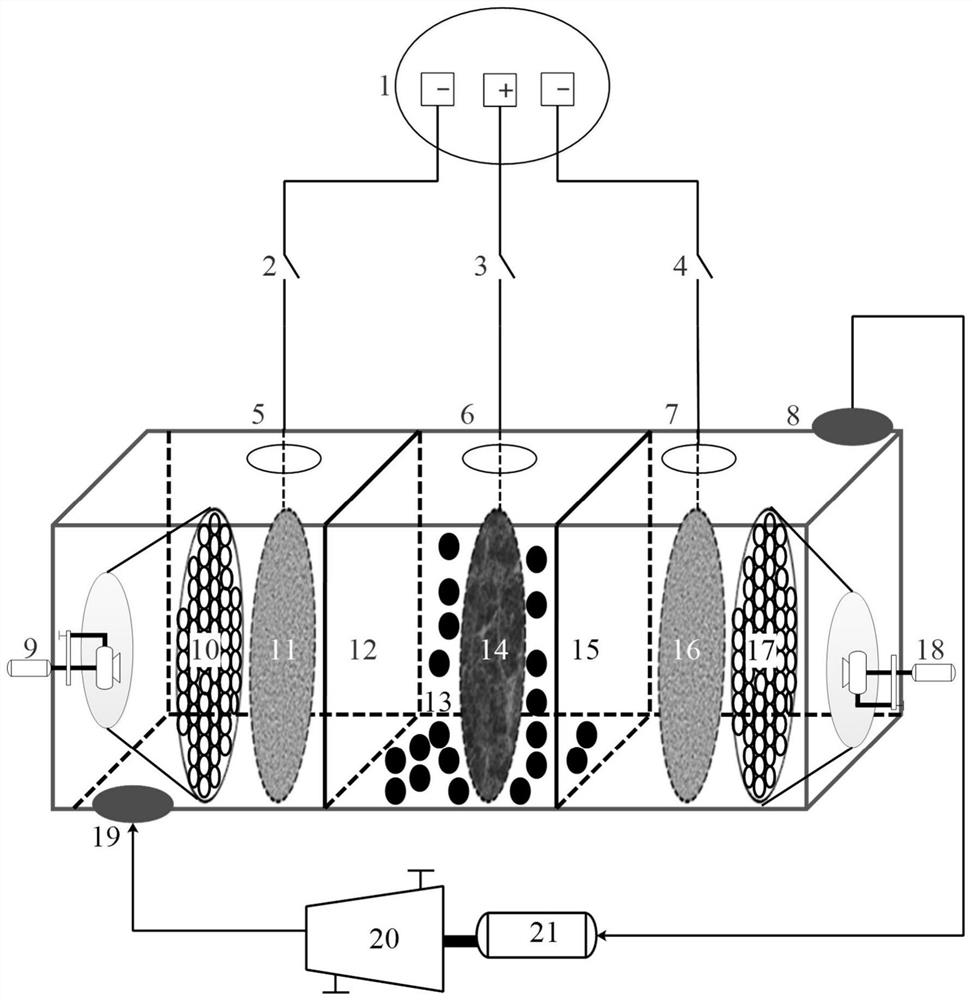

[0057] An in-situ generated hydrogen peroxide and ferrate coupled water treatment deep purification device, the device includes a solution external circulation unit, a deep purification unit, an air pump unit and an electronic control unit; the solution external circulation unit includes a circulation pump 20 and a temporary tank for organic waste water 21. The deep purification unit sequentially includes an anode area and a first cathode area and a second cathode area symmetrically arranged on the left and right sides of the anode area. The first cathode area and the anode area are separated by the first ion exchange membrane 12, and the anode area and the second The cathode area is separated by the second ion-exchange membrane 15, and the vertical horizontal plane of the first cathode area is provided with the first nano-aeration disc 10 and the first electrochemical cathode 11 arranged in parallel with it, and the anode area is provided with the electrochemical anode 14, and ...

Embodiment 2

[0074] Basically the same as Example 1, the difference is that the size is the same as the electrochemical anode 14, the thickness is 7.5mm, the volume ratio of the anode region to the first cathode region or the second cathode region is 1:6, and the monoatomic iron particle electrode 13 is uniformly dispersed in the anode area with a density of 30mg / L.

[0075] The preparation of the electrochemical anode (carbon iron electrode) is as follows:

[0076] 1) After mixing acetylene black, sodium bicarbonate and carbon iron substrate according to the optimal mass ratio of 10:5:100, place them in absolute ethanol and ultrasonically mix to obtain a mixed solution; acetylene black, sodium bicarbonate, 60wt The mass ratio of % polytetrafluoroethylene emulsion and carbon iron substrate is: 10: 5: 100: 100;

[0077] 2) Add 60wt% polytetrafluoroethylene emulsion to the mixed solution prepared in step 1) and stir it in a constant temperature water bath until it becomes a rubbery mixture;...

Embodiment 3

[0084] Basically the same as Example 1, the difference is that the size is the same as the electrochemical anode 14, the thickness is 10mm, the volume ratio of the anode region to the first cathode region or the second cathode region is 1:8, and the monoatomic iron particle electrode 13 Evenly dispersed in the anode area, its density is 50mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com