Composite coating with micron-scale roughness, preparation method and application

A composite coating, micron-level technology, applied in the field of electrodeposition, can solve the problems of large environmental pollution of chromium plating, toxic chromium, and complex process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] According to some embodiments of the present invention, there is also provided a preparation method for the above-mentioned composite coating with micron-scale roughness, comprising the following steps:

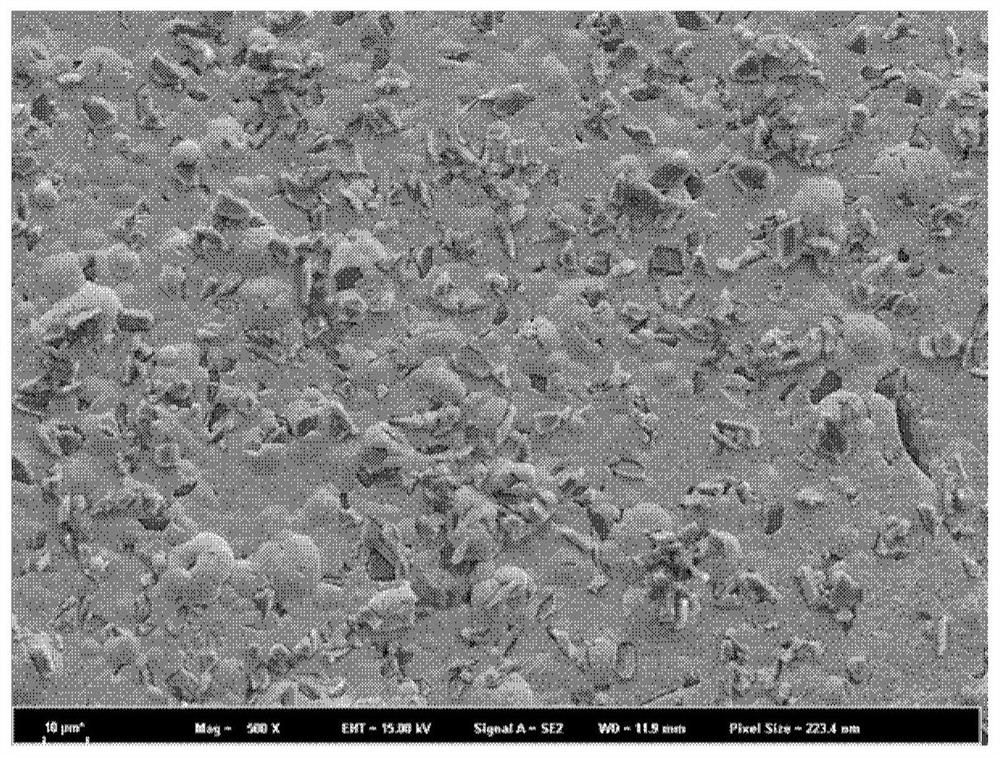

[0026] Step A, uniformly dispersing SiC powder in the basic plating solution containing metal salt to obtain a composite plating solution, wherein the SiC powder contains nano-scale SiC and micron-scale SiC;

[0027] Among them, in order to stably disperse and effectively compound SiC powder in the composite plating solution, it is necessary to carry out pretreatment steps such as degreasing, activation and surface modification of SiC powder to make the surface of SiC powder charge a certain amount. Preferably, after pretreatment, the Zeta potential of the nanoscale SiC surface is between -10 to -40mV or +10 to +40mV, and the Zeta potential of the microscale SiC surface is between -5 to -40mV or +5 to +40mV between.

[0028] More specifically, absolute alcohol can be ...

Embodiment 1

[0043] 1. Preparation of composite plating solution

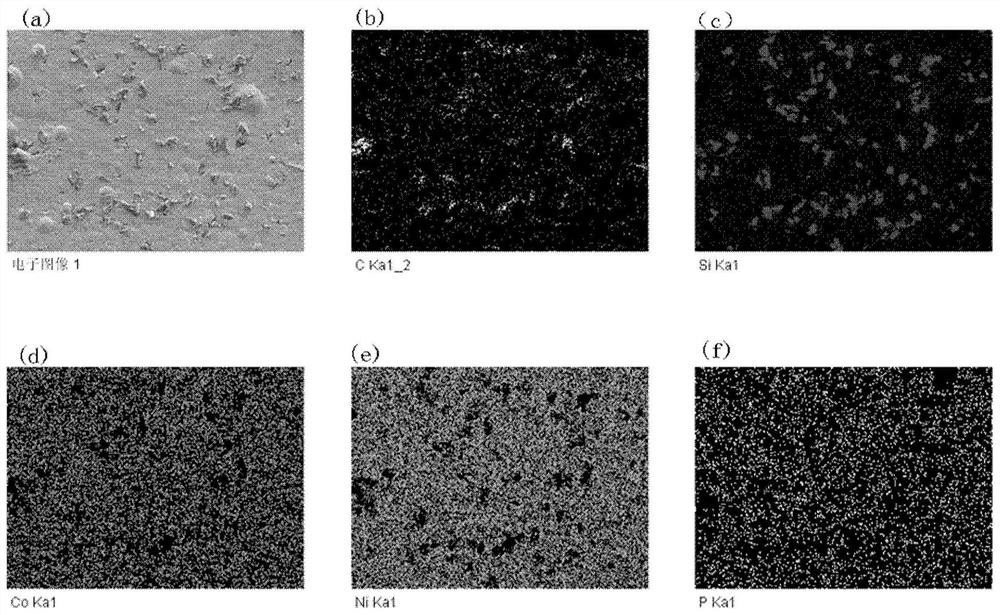

[0044] The composition of the basic plating solution for composite electrodeposition is: nickel sulfate hexahydrate 250g / L, nickel chloride hexahydrate 20g / L, cobalt sulfate heptahydrate 20g / L, boric acid 30g / L, and sodium phosphate 2g / L; The pretreated SiC powder is added to the plating solution, and dispersed uniformly to form a composite plating solution. The particle size and content of the SiC powder are: 40nm SiC 5g / L, 10μm SiC 50g / L.

[0045] Among them, through pretreatment steps such as degreasing and oil removal with anhydrous alcohol, activation with 10% dilute sulfuric acid, and surfactant modification with 0.2g / L sodium dodecylbenzenesulfonate, the Zeta potential of the nano-scale SiC surface is -30± 5mV, the Zeta potential of the micron-sized SiC surface is between -25±5mV, and the SiC powder is uniformly dispersed in the composite plating solution.

[0046] 2. Composite electrodeposition

[0047] In the compo...

Embodiment 2

[0053] 1. Preparation of composite plating solution

[0054] The composition of the basic plating solution for composite electrodeposition is: nickel sulfate hexahydrate 350g / L, nickel chloride hexahydrate 30g / L, boric acid 30g / L; add pretreated SiC powder to the basic plating solution, and disperse evenly to form a composite The particle size and content of the SiC powder in the plating solution are: 300nm SiC 50g / L, 0.6μm SiC 5g / L.

[0055] Among them, through pretreatment steps such as degreasing and oil removal with anhydrous alcohol, activation with 10% dilute sulfuric acid, and surfactant modification with 0.2g / L sodium dodecylbenzenesulfonate, the Zeta potential of the nano-scale SiC surface is -30± 5mV, the Zeta potential of the micron-sized SiC surface is between -25±5mV, and the SiC powder is uniformly dispersed in the composite plating solution.

[0056] 2. Composite electrodeposition

[0057] In the composite plating solution, the 9Cr2Mo alloy steel is used as th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

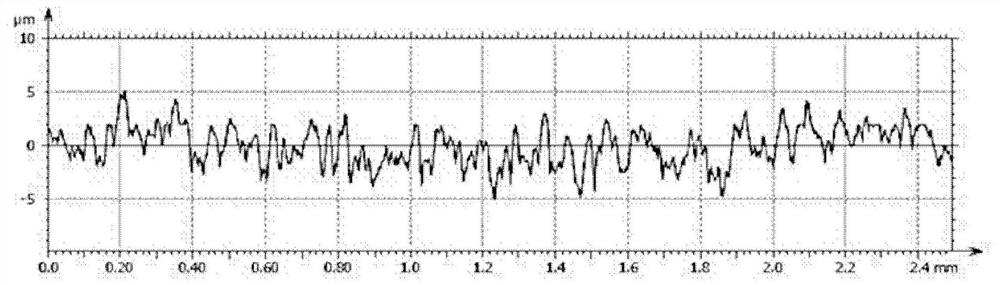

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com