Crystal red phosphorus nanowire and preparation method thereof

A nanowire and red phosphorus technology, which is applied in the field of red phosphorus preparation, can solve the problems of crystalline red phosphorus nanowires, such as time-consuming, unfavorable large-scale preparation, difficulty in large-scale production, and hindering the development of 2D phosphorus nanobelts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

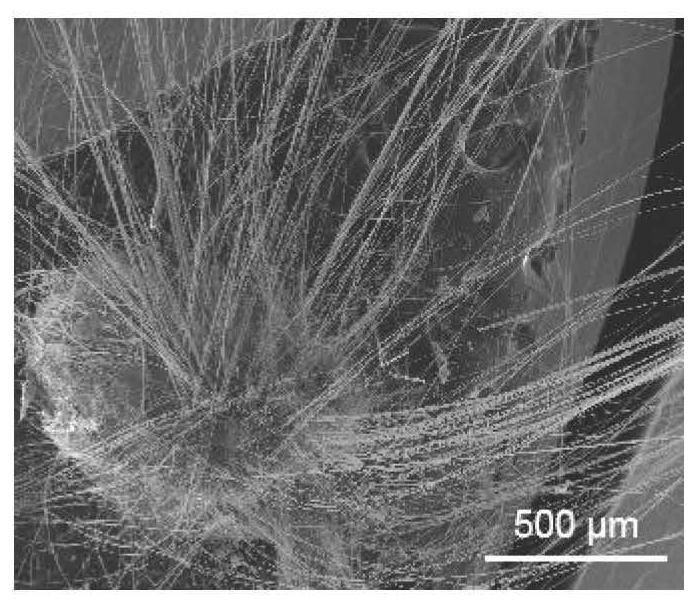

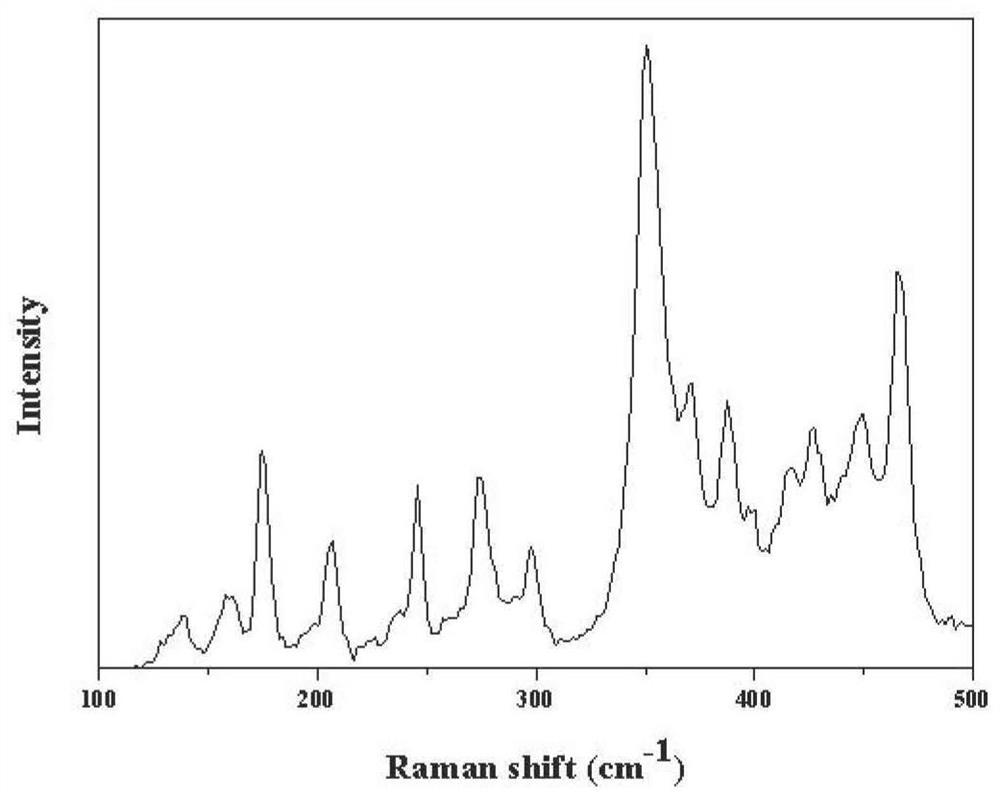

[0023] A preparation method of crystalline red phosphorus nanowires, comprising the following steps:

[0024] (1) In a glove box filled with nitrogen, the mass ratio of red phosphorus, iodine, and tin is weighed to be 10:1:1, and the internal pressure value is controlled to be ≤5.3MPa;

[0025] (2) the material taken by step (1) is added in the quartz tube of 10*1.5*180mm;

[0026] (3) Seal the quartz tube filled with the substance in step (2) at a distance of 80mm from the opening. One end of the quartz tube is a round bottom, and the other end is open. There is a closure 80mm down from the opening, and a 6*10mm quartz column is placed at the sealing place , for safety sealing;

[0027] (4) Place the sealed quartz tube obtained in step (3) in a muffle furnace at room temperature to react, raise the temperature to 612°C at a heating rate of 2.6°C / min, keep it warm for 285min, and lower the temperature at a cooling rate of 0.25°C / min To 480°C, keep warm for 112min, lower the ...

Embodiment 2

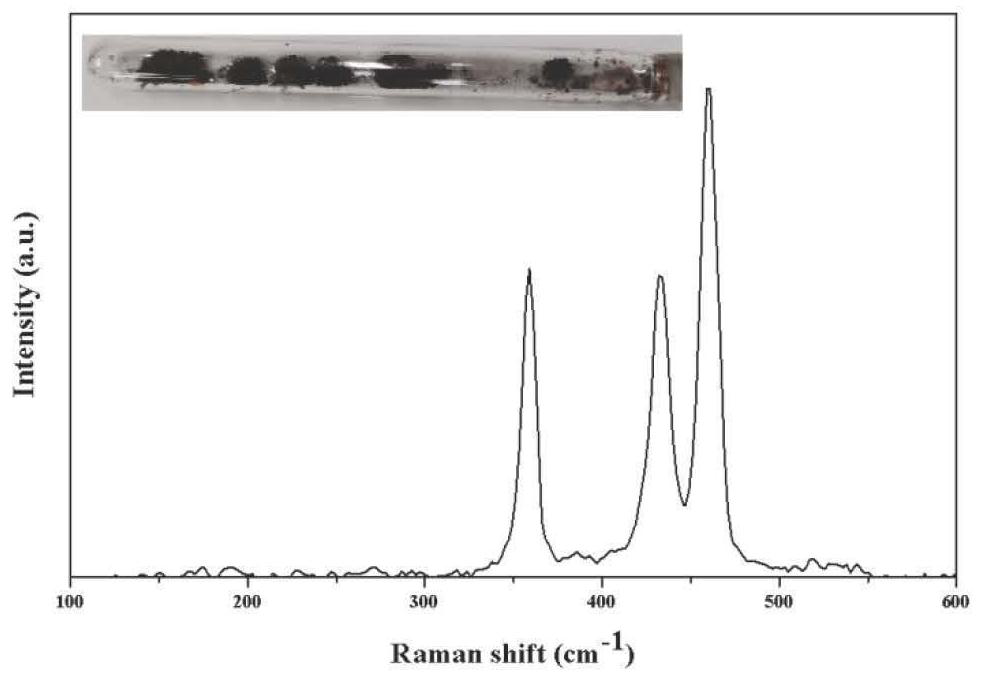

[0031] A preparation method of crystalline red phosphorus nanowires, comprising the following steps:

[0032] (1) In the glove box filled with nitrogen, the mass ratio of red phosphorus, iodine and tin is weighed to be 10:1:1, and the internal pressure value is controlled to 1.0MPa;

[0033] (2) the material taken by step (1) is added in the quartz tube of 10*1.5*180mm;

[0034] (3) Seal the quartz tube filled with the substance in step (2) at a distance of 80mm from the opening. One end of the quartz tube is a round bottom, and the other end is open. There is a closure 80mm down from the opening, and a 6*10mm quartz column is placed at the sealing place , for safety sealing;

[0035] (4) Place the sealed quartz tube obtained in step (3) in a muffle furnace at room temperature to react, raise the temperature to 628°C at a heating rate of 3°C / min, keep it warm for 308min, and lower the temperature at a cooling rate of 0.32°C / min to 488°C, keep warm for 128min, lower the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com