Diffusion absorption type refrigerating machine core using electromagnetic heating mode

An absorption refrigeration and heating technology, applied in refrigerators, energy-saving heating/cooling, induction heating, etc., can solve the problems of long start-up time of refrigeration cores, waste of electric energy, low efficiency, etc., and achieve simple structure and energy saving , not easy to damage the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

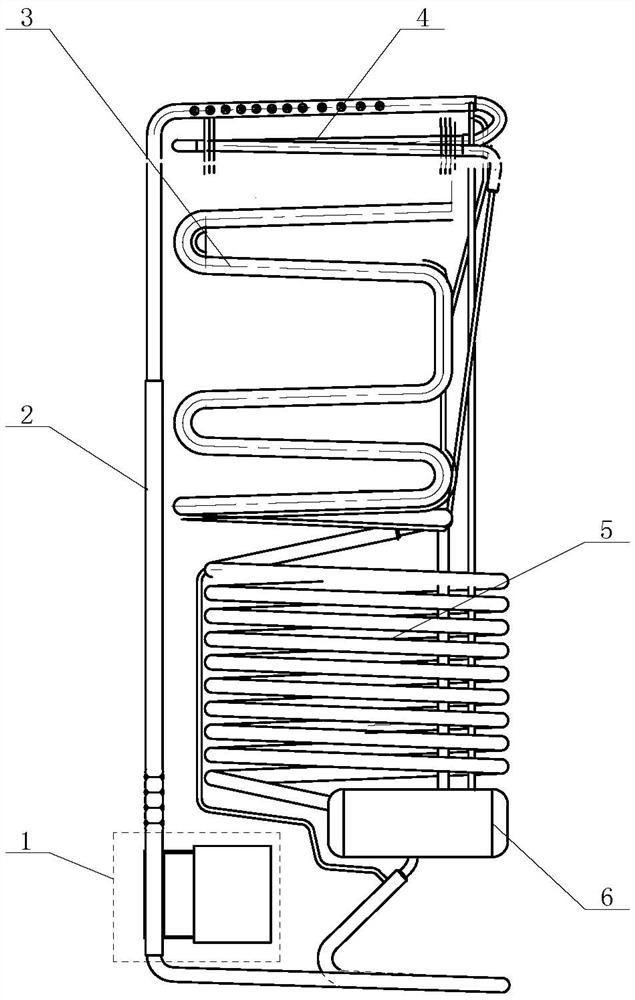

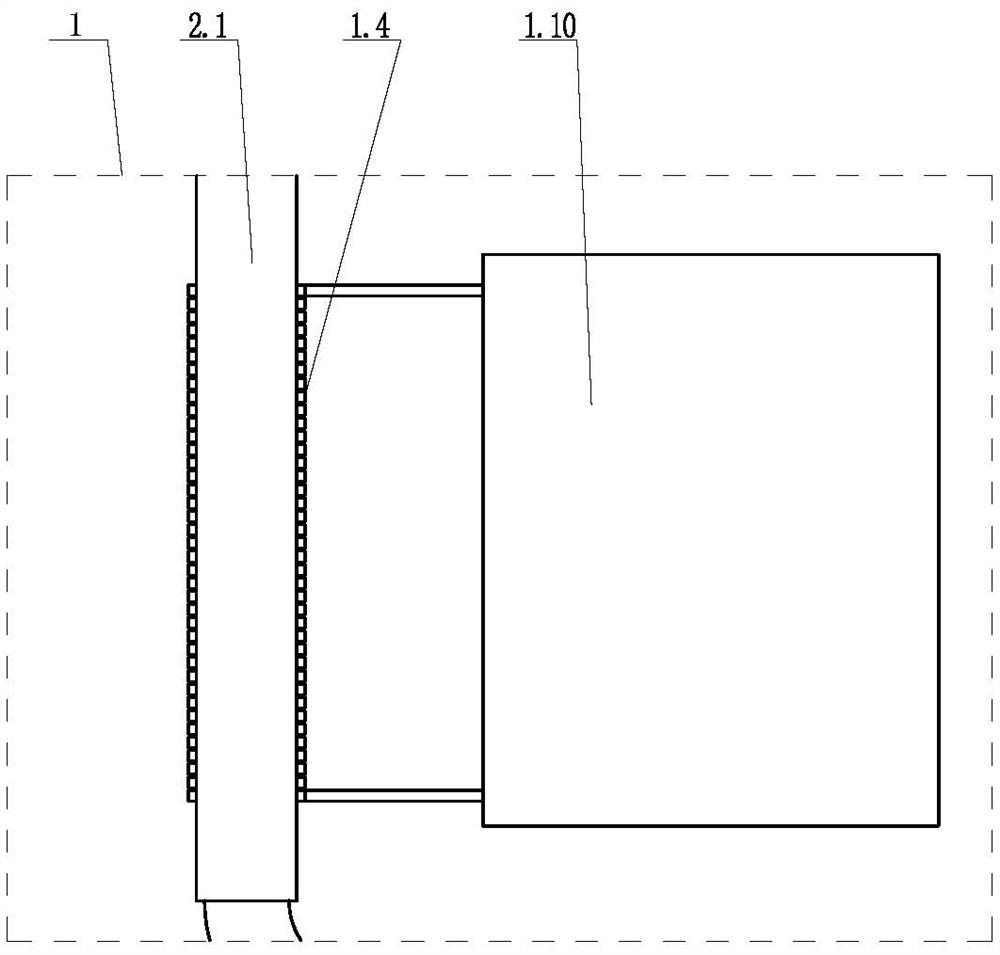

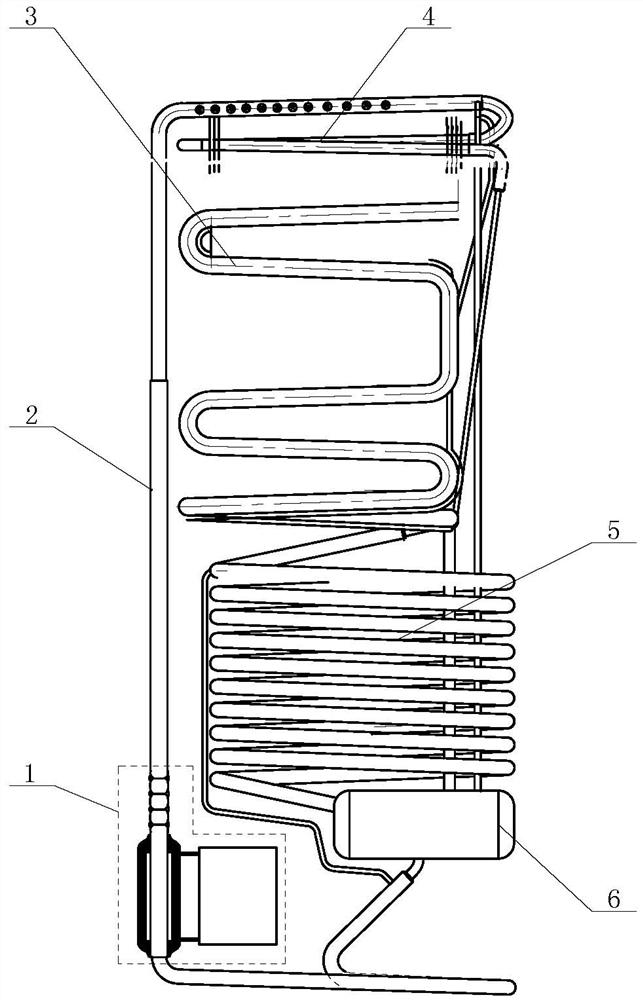

[0033] Such as figure 1 with 2 As shown, a diffusion-absorption refrigeration core using electromagnetic heating according to the present invention includes a generator, a condenser, an evaporator, an absorber, and a liquid storage tank, and the generator, condenser, evaporator, and absorber It is connected with the liquid storage tank through pipelines to form a closed circulation system; a pipeline heating part is installed on the generator, and an electromagnetic medium and high frequency heating device is installed on the pipeline heating part.

[0034] The electromagnetic medium and high frequency heating device includes an electromagnetic induction coil, which is annularly wound on the outer peripheral wall of the pipeline heating part of the generator, and the electromagnetic induction coil is connected with a medium and high frequency power supply.

[0035] The electromagnetic mid-high frequency heating device of the present invention adopts electromagnetic heating to...

Embodiment 2

[0038] Such as image 3 with 4 As shown, the electromagnetic mid-high frequency heating device further includes a winding installation frame body, and the winding installation frame body includes an upper fixing ring, a lower fixing ring, a first ceramic arc plate and a second ceramic arc plate. Such as Figure 5 with 6 As shown, both the upper fixing ring and the lower fixing ring are of split structure, and the two half-ring splits are inserted and buckled to form a ring body. The upper fixing ring and the lower fixing ring are clamped and fixed on the upper part and the lower part of the pipeline heating part respectively. A plurality of upper insertion grooves and lower insertion grooves are annularly provided on the outer circumferences of the upper fixed ring and the lower fixed ring. Such as Figure 7 As shown, two first upper pins are fixed on the upper end of the first ceramic arc plate, two first lower pins are fixed on the lower end of the first ceramic arc pla...

Embodiment 3

[0042] In this embodiment, the length of the pipeline heating part is 15-55 cm.

[0043] The rest of the structures and implementations are the same as those in Embodiment 1 or 2, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com