Intensive care unit patient nursing drainage phlegm eliminating device

An expectorant and patient technology, applied in the medical field, can solve the problems of inability to drain phlegm and adjust the position of the patient, unable to flap the patient's back, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

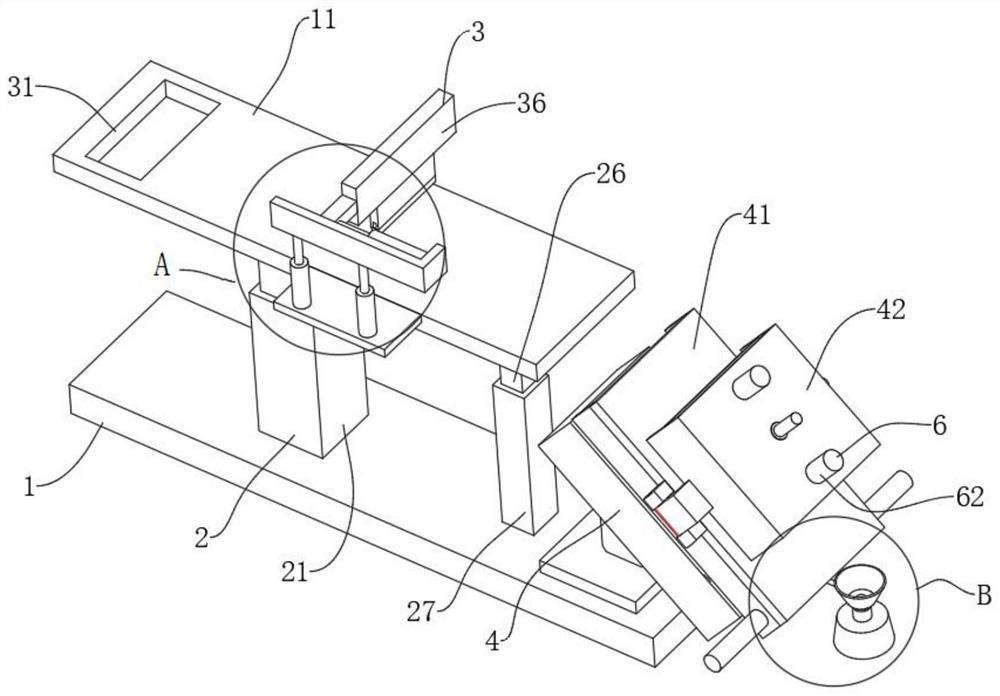

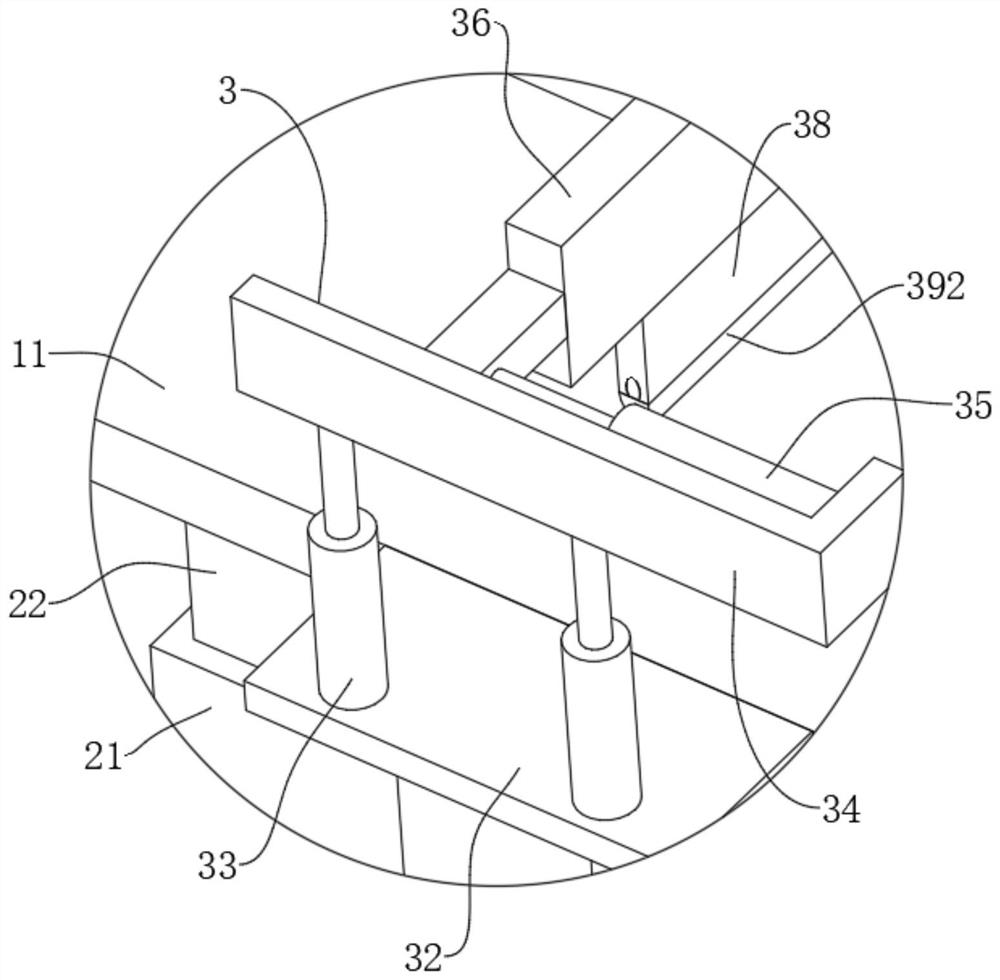

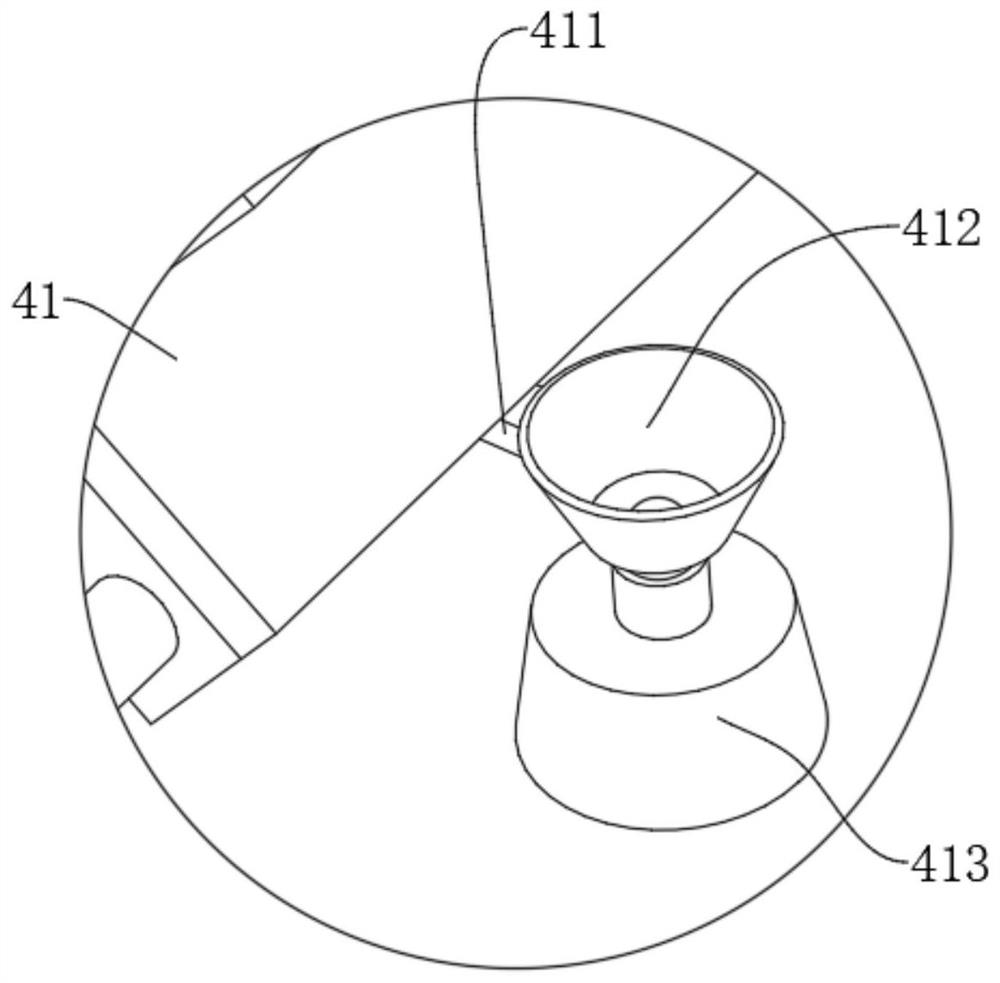

[0050] like figure 1 , figure 2 and Figure 4 As shown, a kind of ICU patient nursing drainage and expectorant device mainly is made up of following several parts: comprise base 1, wherein base 1 is the main body part of this device; The support plate 11 can be used for patients to climb and lie down; the first power assembly 2 for driving the support plate 11 to slide vertically can drive the support plate 11 to slide vertically; The scraping massage component 3 for scraping massage on the patient's back can achieve the effect of scraping and scraping the patient's back by using the scraping massage component 3, and improve the patient's ability to expectorate; swing the fixed box 4 arranged above the base 1; parallel The sliding climbing board 41 of the fixed box 4 surface, wherein the climbing board 41 can be used for the patient to climb and lie down; the second power assembly 5 for driving the climbing board 41 to move can move the climbing board 41 under the drive of ...

Embodiment 2

[0063] The difference from Example 1 is that the surface of the support plate 11 is coated with an antifouling coating, wherein the preparation process of the antifouling coating is as follows:

[0064] S1. Select 40 parts of methyl trimethoxy silicon epoxy, 20 parts of phenyl trimethoxy silicon epoxy, 10 parts of stannous octoate, 10 parts of dibutyl tin dilaurate, 20 parts of polyvinyl acetate, pyridyl sulfide Ketone copper 20 parts, acrylate 20 parts, polydimethylsiloxane 15 parts, methacrylate 15 parts;

[0065] S2. Add methyl trimethoxy silicon epoxy, phenyl trimethoxy silicon epoxy, stannous octoate, dibutyl tin dilaurate, and polyvinyl acetate into the reaction kettle and mix evenly, then heat it to The temperature is 80°C, and keep warm for 30min;

[0066] S3. Use aerodynamic sandblasting method to derust and roughen the surface of support plate 11. Use 20 mesh white corundum for sandblasting. The pressure of compressed air during sandblasting is 0.5MPa, the sandblast...

Embodiment 3

[0071] The difference from Example 2 is the preparation of antifouling coating, wherein the preparation process of antifouling coating is as follows:

[0072] S1. Select 38 parts of methyl trimethoxy silicon epoxy, 24 parts of phenyl trimethoxy silicon epoxy, 15 parts of stannous octoate, 14 parts of dibutyltin dilaurate, 25 parts of polyvinyl acetate, pyridyl sulfide Ketone copper 20 parts, acrylate 20 parts, polydimethylsiloxane 15 parts, methacrylate 12 parts;

[0073] S2. Add methyl trimethoxy silicon epoxy, phenyl trimethoxy silicon epoxy, stannous octoate, dibutyl tin dilaurate, and polyvinyl acetate into the reaction kettle and mix evenly, then heat it to The temperature is 75°C, and keep warm for 30min;

[0074] S3. Use aerodynamic sandblasting method to derust and roughen the surface of support plate 11. Use 24 mesh white corundum for sandblasting. The pressure of compressed air during sandblasting is 0.6MPa, the distance of sandblasting is 120mm, and the angle of sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com