Indirect thermal forming large-tonnage hydraulic machine

A hydraulic press and thermoforming technology, applied in the direction of stamping machines, presses, forming tools, etc., can solve the problems of large-mass body motion control, high difficulty in inertia control, high difficulty in realizing process curves, large size, and heavy weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

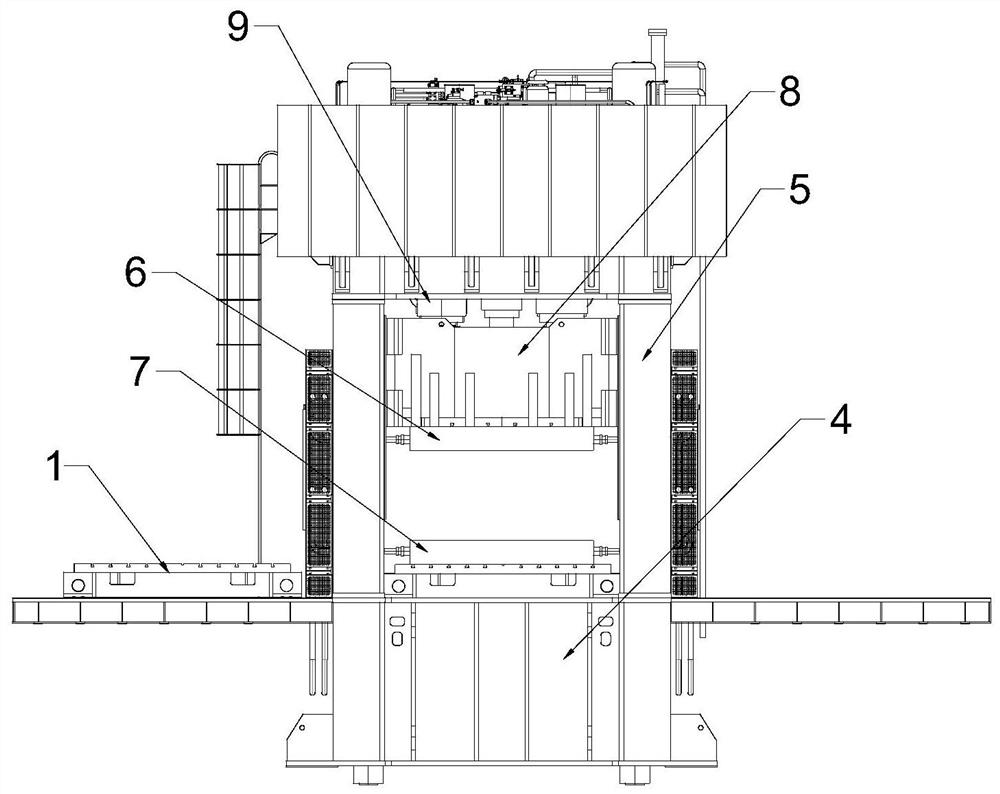

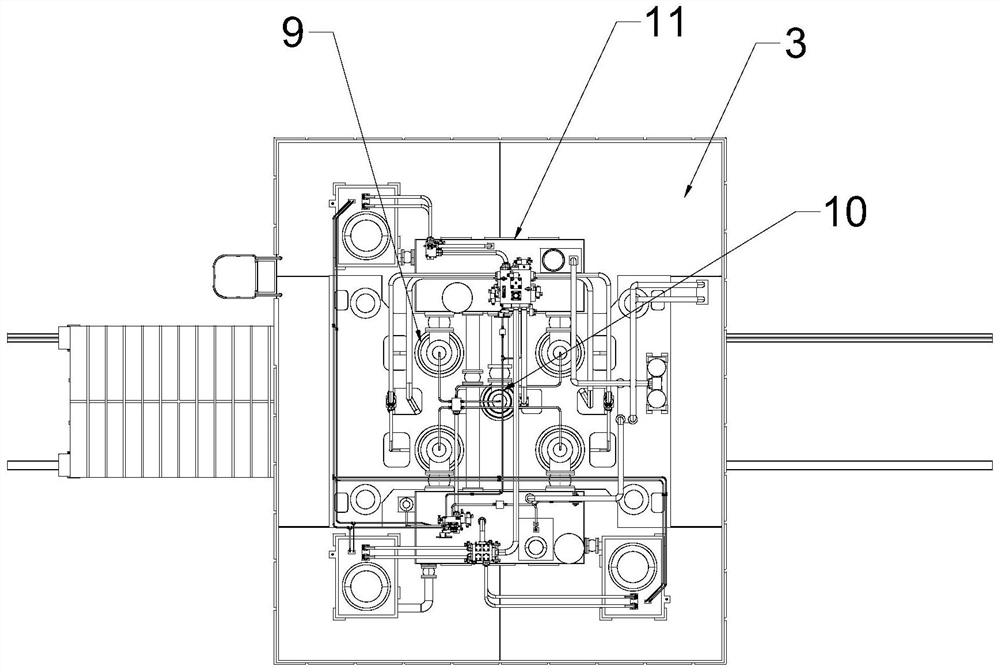

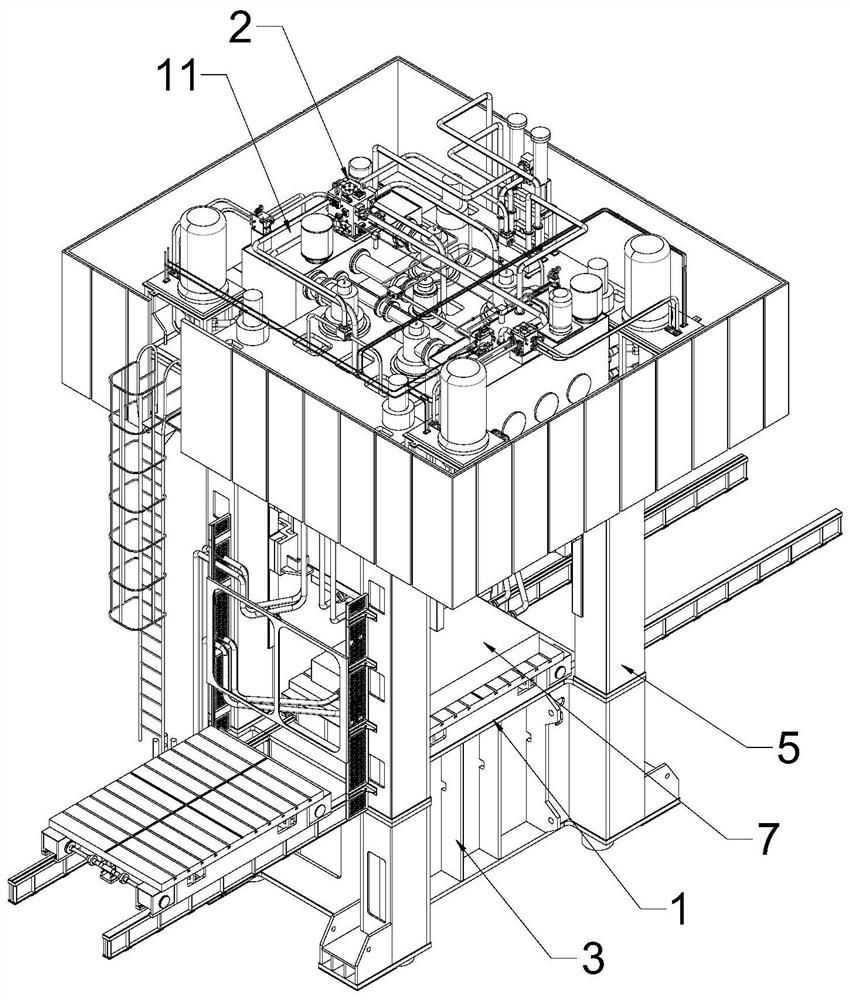

[0031] see Figure 1-3 , a large-tonnage hydraulic press for indirect thermoforming, including a mobile workbench 1, an electrical cabinet 2, and a hydraulic mechanism; the hydraulic mechanism includes an upper beam 3, a lower beam 4, and a column 5, and four columns 5 are fixed to the lower beam 4 of the hydraulic machine. The four corners of the top surface extend upwards and are connected and fixed with the bottom surface of the upper beam 3 of the hydraulic machine. Two mobile workbenches 1 are symmetrically arranged on both sides of the top surface of the lower beam 4 of the hydraulic machine. The middle position of the column 5 is provided with an upper mold base 6 and a lower mold base 7, the lower mold base 7 is fixed on the top surface of the lower beam 4 of the hydraulic press, the upper mold base 6 is fixed on the bottom surface of the slider 8, and the top surface of the upper beam 3 of the hydraulic press is provided with three Plunger cylinder 9 and two piston cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com