Welding drilling device applied to formwork

A technology of punching device and template, applied in positioning device, clamping, supporting and other directions, can solve the problems of inconsistent size, prone to error, slurry leakage, etc., and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

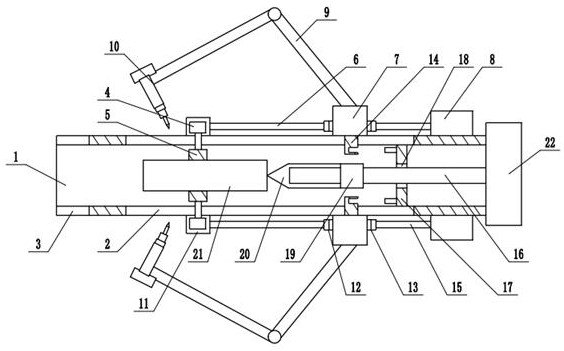

[0029] This example: see figure 1 , the welding and punching device applied to the formwork, including the positioning cylinder 1 facing the template and the embedded sleeve 21 located in the positioning cylinder 1, the positioning cylinder 1 is provided with three slides distributed in the circumferential direction with the center line as the center of the circle along the length direction of the positioning cylinder 1. Groove 2, each chute 2 is provided with a clamping piece that slides along its length and can be used to clamp the embedded sleeve 21; the outside of the positioning cylinder 1 is provided with a rotating ring 7, and the corresponding setting is directly below the rotating ring 7 In the ring groove on the positioning cylinder 1, one side of the rotating ring 7 is connected to the clamping member through the first push rod 6, and a left magnet a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com