Using method of grinding equipment for automobile casting production

A technology for castings and equipment, which is applied in the field of grinding equipment for the production of automobile castings, which can solve the problems of the space occupied by the dust removal device, the inability to arrange the grinding equipment, and the mixing of water mist, etc., and achieve the effect of sufficient spraying and dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

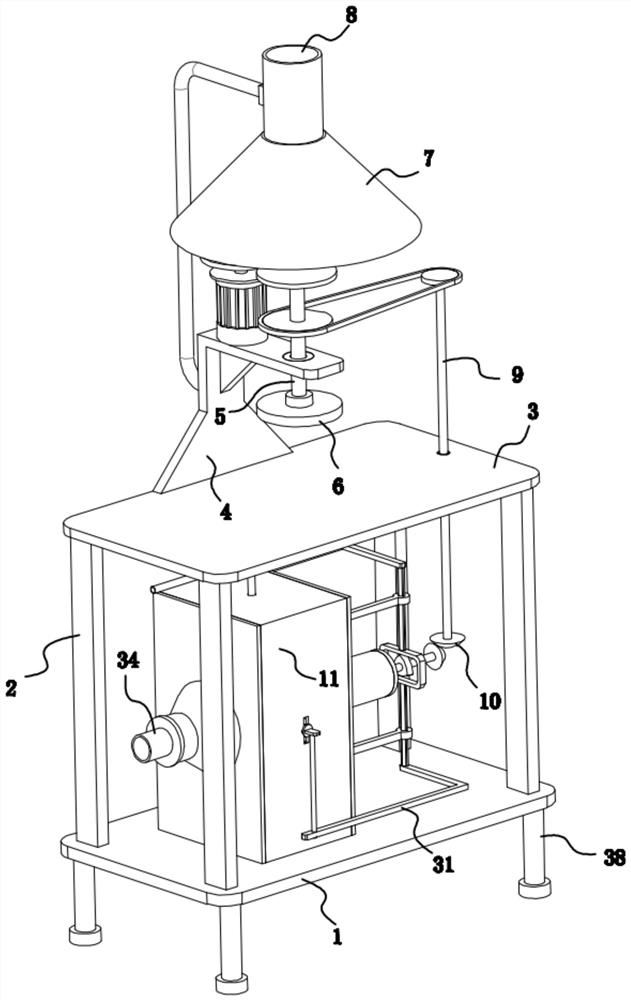

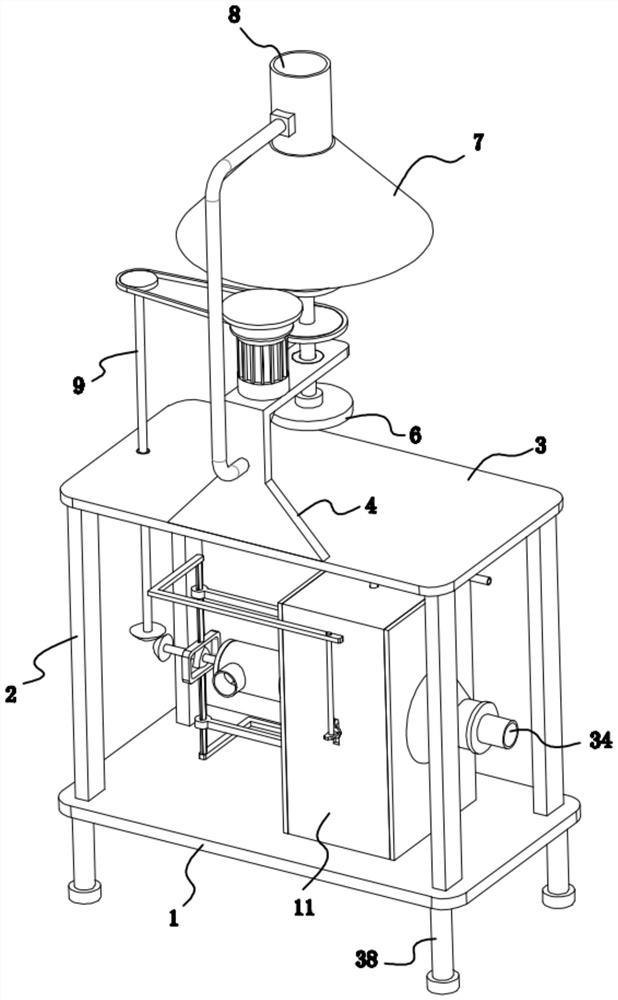

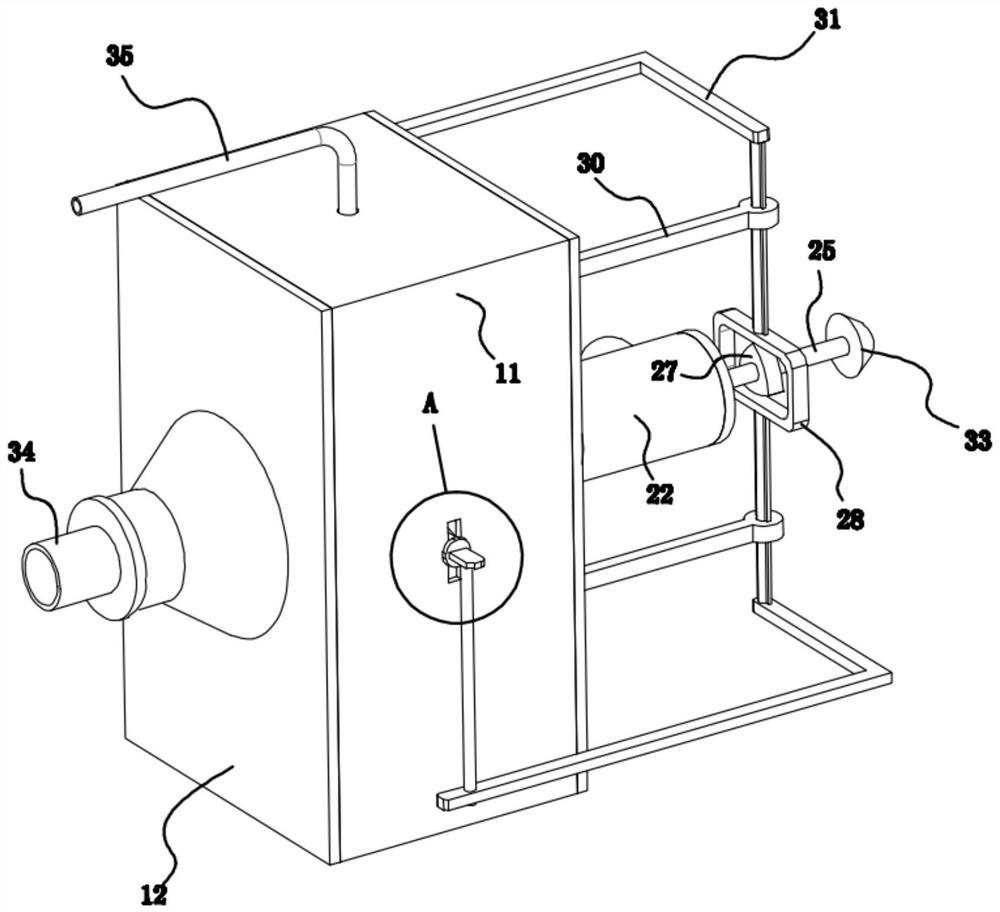

[0044] refer to Figure 1-9 , a method for using a grinding device for the production of automobile castings, comprising the steps of:

[0045] S1. Take a grinding device for the production of automobile castings. The grinding device includes a base plate 1. Four support plates 2 distributed in a rectangular shape are fixedly installed on the upper surface of the base plate 1. The top ends of the four support plates 2 are fixedly connected to the same workbench 3. On the upper surface of the workbench 3, a mounting frame 4 is fixedly installed, and a driving shaft 5 is rotatably mounted on the mounting frame 4. The first conical cover 7 placed directly above the drive shaft 5 is also fixedly installed on the mounting bracket 4, and the top of the first conical cover 7 is fixedly provided with an air outlet pipe 8 communicating with it inside, and the upper surface of the bottom plate 1 The spray dust removal module is fixedly installed, the air outlet pipe 8 is connected with...

Embodiment 2

[0072] refer to Figure 1-9 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the first transmission mechanism includes a transmission shaft 9, a first bevel gear 10, and a second bevel gear 33, and the workbench 1 is rotatably installed with The drive shaft 5 is provided with a drive shaft 9, which is connected to the drive shaft 5. The bottom end of the drive shaft 9 extends downward to the bottom of the workbench 1 and is fixedly installed with the first bevel gear 10 coaxially arranged therewith. The rotating shaft 25 A second bevel gear 33 meshing with the first bevel gear 10 is fixedly installed on the top.

[0073] Transmission between the transmission shaft 9 and the drive shaft 5 can be carried out by means of chain transmission. When the drive shaft 5 rotates, the drive shaft 5 drives the transmission shaft 9 to rotate, and the transmission shaft 9 drives the first bevel gear 10 to rotate, and the first bevel gear 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com