Natural gas liquefaction heavy hydrocarbon and benzene removal system

A technology for removing heavy hydrocarbons and natural gas, which is applied in the direction of gas fuel, gas treatment, chemical instruments and methods, etc. It can solve the problems of heavy hydrocarbon removal and benzene system hydrocarbon content exceeding the standard, heavy hydrocarbon and aromatic hydrocarbon content increase, and overcooling in the cold box Problems such as heat exchanger blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

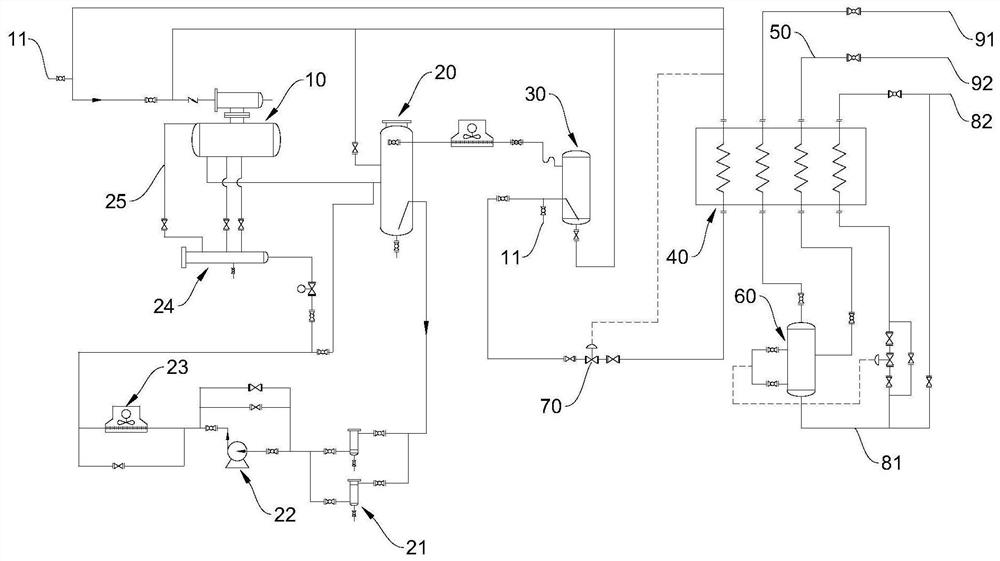

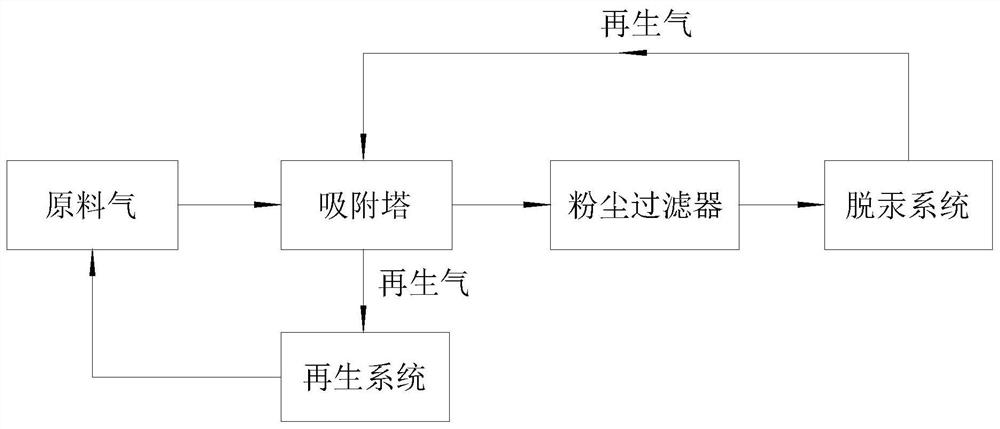

[0027] A system for removing heavy hydrocarbons and benzene from natural gas liquefaction, including an adsorption tower. There are two adsorption towers, one for adsorption and the other for regeneration; the adsorption tower is connected to a regeneration system, and the regeneration system includes regeneration gas heating The regeneration gas cooler, the regeneration gas separator and the regeneration gas dehydrogenation skid; the cooling temperature of the regeneration gas dehydrogenation skid is -30℃~-20℃.

[0028] The invention provides a natural gas liquefaction system for removing heavy hydrocarbons and benzene. The dehydrated and purified natural gas enters an adsorption tower, and the activated carbon in the adsorption tower adsorbs and removes aromatic hydrocarbon impurities in the natural gas, and then takes out the dust through a dust filter. Enter the natural gas mercury removal system; when the adsorption tower is not adsorbing, it will be regenerated through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com