Composite roll for welded steel pipe and cold-formed steel and preparation method thereof

A technology of composite roll and cold-formed steel, applied in the field of roll manufacturing, can solve the problems of affecting the speed and accuracy of end face finishing, unable to achieve bimetallic composite, difficult machining, etc., to ensure performance, shorten processing cycle, improve The effect of machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

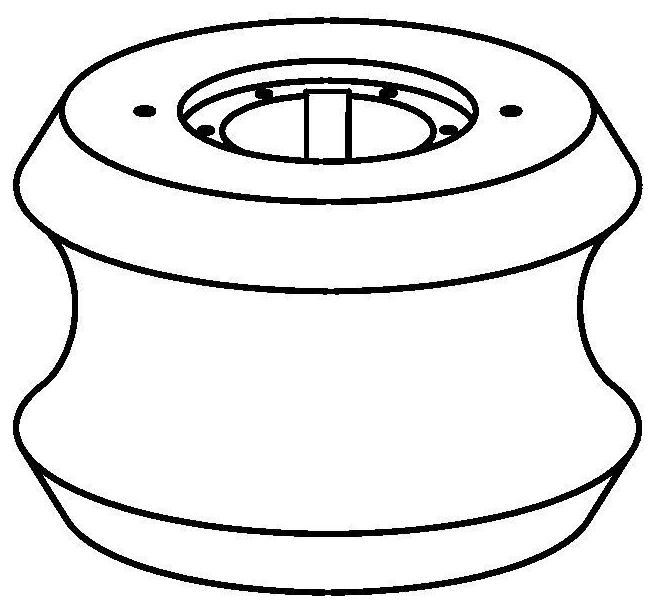

[0043] Such as figure 1 As shown, Example 1 is the fine-formed lower roll for manufacturing welded pipe units. The roll length is 240mm, the maximum outer diameter is Ф380mm, the minimum outer diameter is Ф220mm, the inner hole diameter is Ф125mm, the weight of the finished product is 105kg / piece, and there are two M12×40 on each end. The hoisting screw holes and 4 M12×25 assembly screw holes, the maximum position of the screw hole that can be processed is Ф230.

[0044] The graphite steel matrix components of Example 1 are shown in Table 1 by weight percentage (%Wt).

[0045] Table 1 graphite steel matrix components by weight percentage (%Wt)

[0046] C Si mn P S Ni Al Zr Ce RE Fe 2.00 1.40 0.25 0.015 0.021 0.51 0.22 0.06 0.03 0.02 margin

[0047] Example 1 The working layer of the welded pipe unit uses the fine-forming lower roll to add tungsten carbide particles into the molten graphite steel matrix for casting. The amount of tu...

Embodiment 2

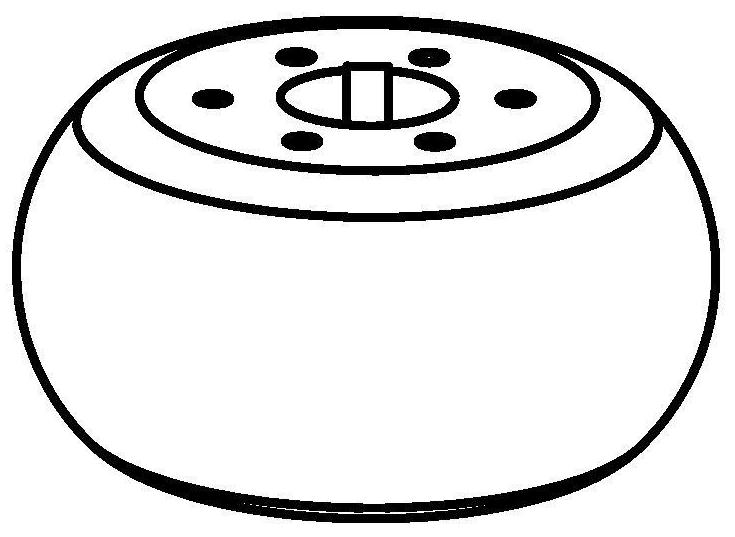

[0053] Such as figure 2 As shown, Example 2 is the rough forming upper roll for manufacturing welded pipe unit, the roll length is 410mm, the maximum outer diameter is Ф660mm, the minimum outer diameter is Ф400mm, the inner hole diameter is Ф125mm, and the weight of the finished product is 694kg / piece. There are 2 M16×60 hoisting screw holes and 4 M12×40 assembly screw holes on each of the two ends, and the maximum screw hole processing position is Ф245.

[0054] Example 2 The components of the graphite steel matrix are shown in Table 2 by weight percentage (%Wt).

[0055] Table 1 graphite steel matrix components by weight percentage (%Wt)

[0056] C Si mn P S Ni Al Zr Ce RE Fe 1.70 1.60 0.22 0.014 0.017 0.58 0.27 0.05 0.04 0.03 margin

[0057] Example 2 The working layer of the rough forming upper roll blank for the welded pipe unit uses graphite steel matrix melt, the amount of tungsten carbide particles added is 17% of the weig...

Embodiment 3

[0063] Such as figure 1 As shown, Example 3 is for the production of precision-formed side rolls for welded pipe units. The roll length is 160mm, the maximum outer diameter is Ф240mm, the minimum outer diameter is Ф210mm, the inner hole diameter is Ф95mm, and the weight of the finished product is 33kg / piece. There are 2 M12×25 hoisting screw holes and 4 M10×20 assembly screw holes on each of the two ends, and the maximum screw hole processing position is Ф150.

[0064] Example 3 The components of the graphite steel matrix are shown in Table 2 by weight percentage (%Wt).

[0065] Table 1 graphite steel matrix components by weight percentage (%Wt)

[0066] C Si mn P S Ni Al Zr Ce RE Fe 1.50 1.00 0.3 0.02 0.019 0.42 0.25 0.04 0.05 0.03 margin

[0067] The working layer of the fine-formed side roll blank of the welded pipe unit is cast with graphite steel matrix melt by adding tungsten carbide particles with a weight of 15% of the work...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com