780mpa grade hot-rolled steel plate for hydraulic bulging and its preparation method

A technology of hydraulic bulging and hot-rolled steel plates, which is applied in metal rolling, heat treatment equipment, manufacturing tools, etc., can solve the problems of poor formability of high-strength steel, achieve high fatigue performance, suppress dislocation disappearance, and increase bit density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

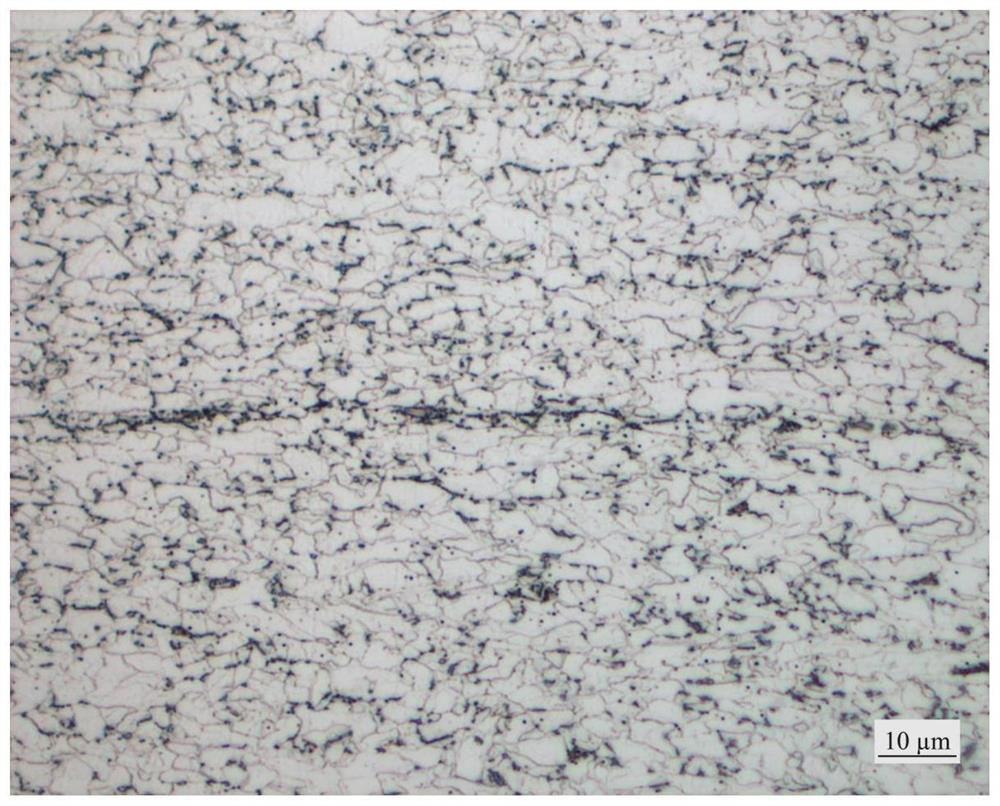

Image

Examples

preparation example Construction

[0030] The preparation method of the above-mentioned 780MPa level hydraulic bulging hot-rolled steel plate comprises the following steps:

[0031] a. Prepare billets according to the chemical composition of hot-rolled steel plates for 780MPa grade hydraulic bulging;

[0032] b. Rough rolling: rough rolling the heated billet for 5-7 passes to obtain an intermediate billet, controlling the deformation of each pass in the first 2 passes to be ≥18%, and the deformation of each pass in the remaining passes to be ≥20%;

[0033] c. Finish rolling: the start rolling temperature is 1020-1080°C, the finish rolling temperature is 850-900°C, and the thickness of the steel plate after finish rolling is 2-8mm;

[0034]d. Laminar cooling: the steel plate obtained in step c is ultrafast cooled to 580-640° C. at a cooling rate of >60° C. / s.

[0035] In the above step a, the conventional converter smelting process is adopted, the molten iron desulfurization→converter smelting combined blowing→...

Embodiment

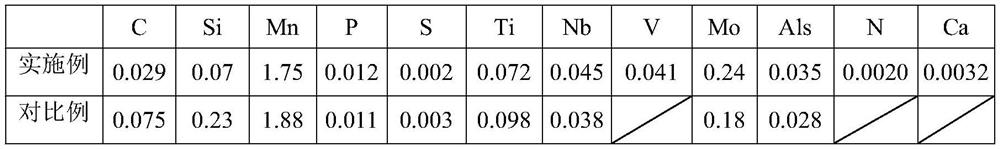

[0045] This embodiment provides 5 groups of 780MPa grade hot-rolled steel sheets for hydraulic bulging prepared by the preparation method of the present invention, such as examples 1, 2, 3, 4 and 5, and 780MPa grades in examples 1, 2, 3, 4 and 5 The components of the hot-rolled steel sheets for hydraulic bulging are designed to be the same, as shown in the examples in Table 1. The present invention provides two groups of comparative examples, such as comparative examples 1 and 2, the chemical components of comparative examples 1 and 2 are the same, as shown in the comparative examples in Table 1.

[0046] The chemical composition of table 1 embodiment and comparative example

[0047]

[0048] The preparation of the 780MPa level hydraulic bulging hot-rolled steel plate of example 1, 2, 3, 4 and 5 comprises the steps:

[0049] a. Using conventional converter smelting process, molten iron desulfurization→converter smelting combined blowing→deoxidation, alloying→replenishing A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com