Anti-collision device

A technology of anti-collision devices and damping devices, which is applied in construction, bridge construction, bridges, etc., can solve problems such as premature failure, damage to energy-consuming devices, and limited energy-consuming components, and achieve a large range of protection capabilities and energy-consuming processes. Smooth, energy-efficient way of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

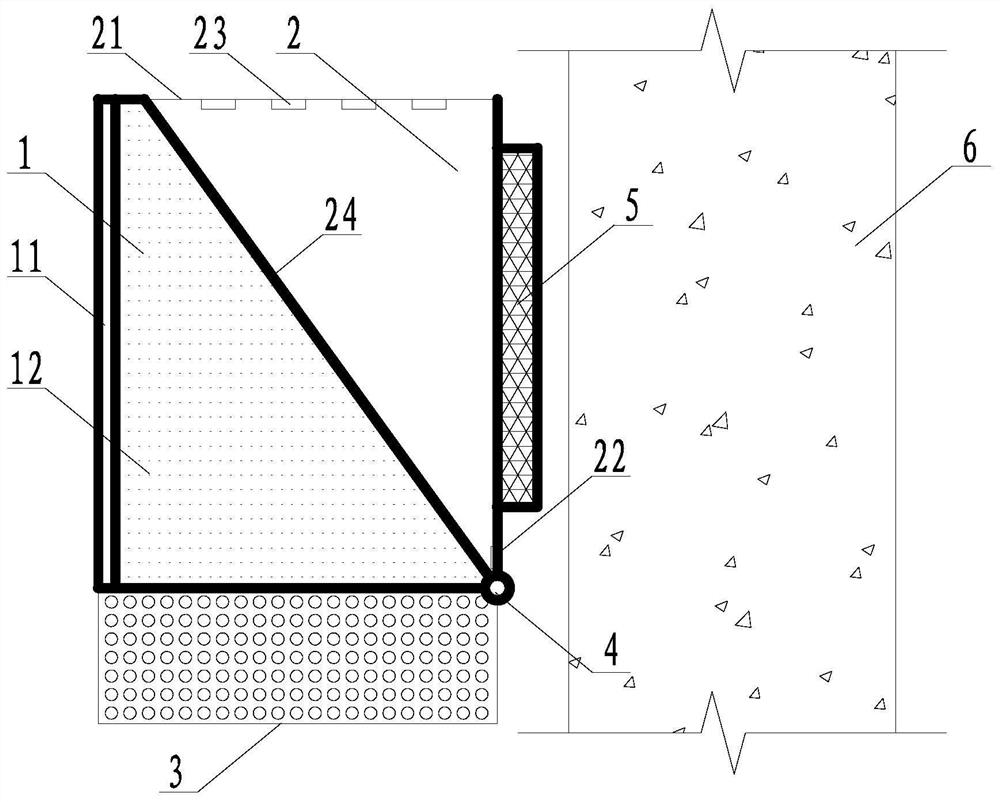

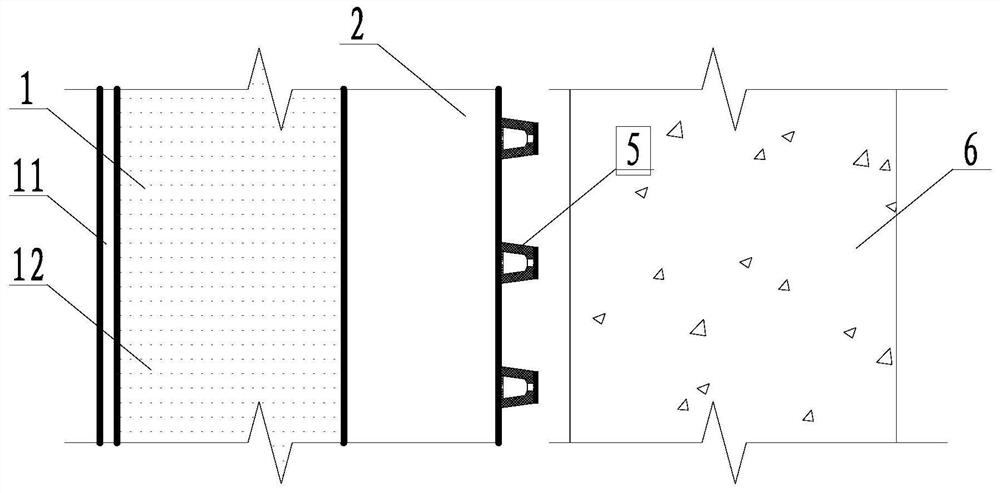

[0049] Such as figure 1 , figure 2 As shown, the anti-collision device of this embodiment is used for the anti-collision of the bridge pier 6, including a force transmission assembly 1 and a water tank 2 containing a water medium inside; the force transmission assembly 1 includes a collision panel 11 and is connected to the collision panel The energy-dissipating material layer 12 on one side of 11, the collision panel 11 is set on the side of the force transmission component 1 that is subjected to impact, and is composed of ultra-high performance concrete and steel plates, and the energy-dissipating material layer 12 is arranged on the collision panel 11 and The water tank 2 is made of polyurethane foam material; the bottom of the force transmission component 1 is provided with a lightweight external water permeable box 3, and the water permeable box 3 is a box body with multiple openings on the box wall, and is made of rubber material.

[0050] The water tank 2 includes a w...

Embodiment 2

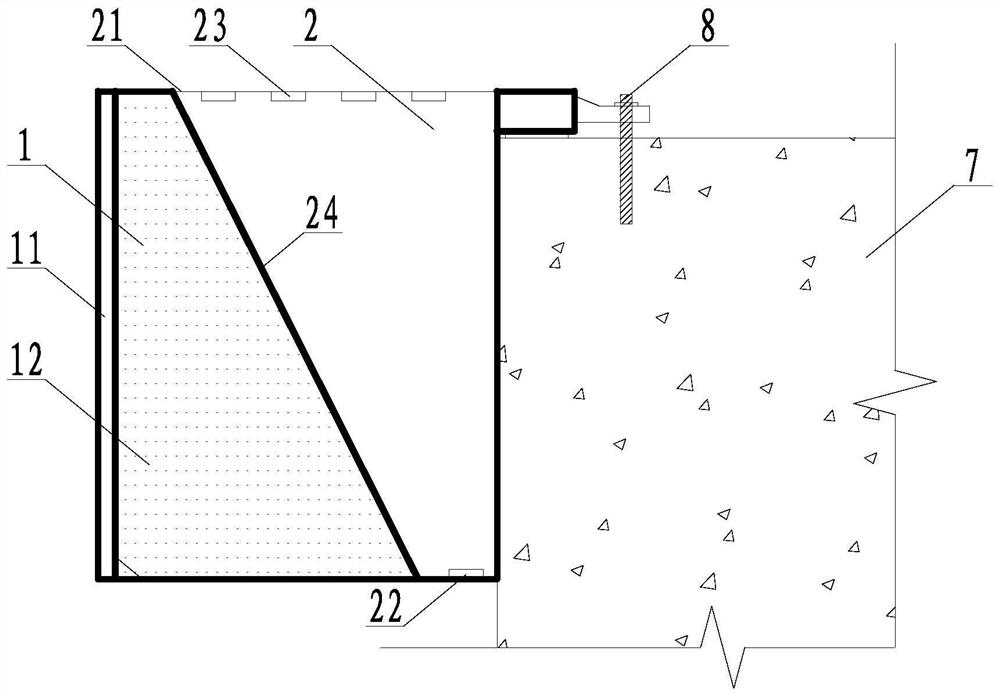

[0056] Such as image 3 , Figure 4 As shown, the anti-collision device of this embodiment is used for the anti-collision of the platform 7, and includes a force transmission assembly 1 and a water tank 2 containing a water medium inside; the force transmission assembly 1 includes a collision panel 11 and a The energy-dissipating material layer 12 on one side of the panel 11, the collision panel 11 is set on the side of the force transmission component 1 that receives the impact, and is composed of ultra-high-performance concrete and steel plates, and the energy-dissipating material layer 12 is polyurethane foam material. Between the collision panel 11 and the water tank 2 .

[0057] The water tank 2 includes a water tank roof 21 and a water tank wall 24, the water tank roof 21 is made of a superelastic material, the water tank 2 is closely connected with the force transmission component 1, and the water tank wall 24 at the connecting surface transmits force to the One side ...

Embodiment 3

[0063] Such as Figure 5 , Image 6 As shown, the anti-collision device of this embodiment is used for the anti-collision of the bearing platform 7, and includes a force transmission component 1 and a water tank 2 containing a water medium inside, and the water tank 2 is in the shape of a cylindrical barrel; The collision panel 11 and the energy-dissipating material layer 12 connected to the side of the collision panel 11, the collision panel 11 is arranged on the side of the force transmission component 1 that receives the impact, and is composed of ultra-high performance concrete and steel plates. The energy-dissipating material The layer 12 is made of polyurethane foam, which is arranged between the collision panel 11 and the water tank 2; the bottom of the force transmission component 1 is provided with a rotary paddle 9, which is connected to the water tank 2, and a rotatable rotating rod 10 is provided. , made of composite material board with good durability; there are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com