Gasification incineration boiler for high-nitrogen organic waste liquid containing heavy metal, metal salt and phosphorus

A technology of organic waste liquid and metal salts, applied in incinerators, combustion chambers, combustion methods, etc., can solve the problems of high denitrification costs and difficulties in flue gas emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

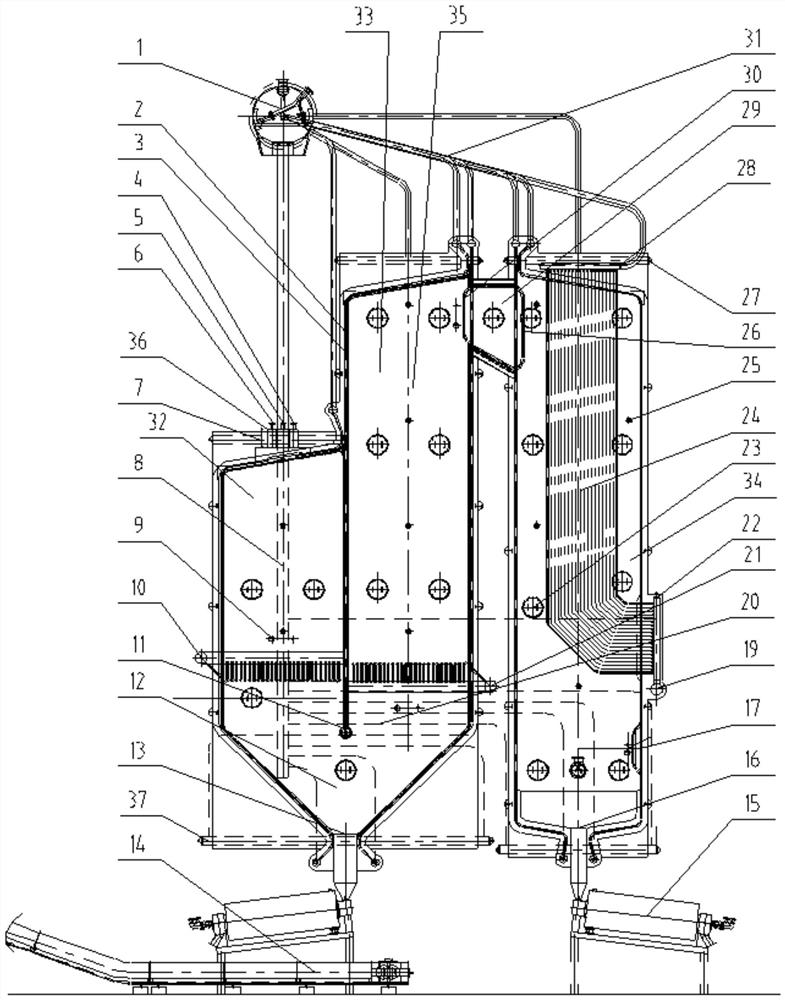

[0030] This embodiment discloses a gasification and incineration boiler for organic waste liquid containing heavy metals, metal salts and phosphorus and high nitrogen, which includes a U-shaped gasification and incineration boiler 35 and a cooling chamber 34 with a built-in L-shaped hanging screen heating surface. The gasification incineration boiler 35 and the cooling chamber 34 with the built-in L-shaped hanging screen heating surface are in an inverted "U" shape.

[0031] One side of the U-shaped gasification and incineration boiler 35 is a gasification chamber 32, and the other side is a high-temperature incineration chamber 33. The gasification chamber 32 and the high-temperature incineration chamber 33 are separated by a membrane-type water-cooled partition wall 11; The bottom end of the incineration chamber 32 is connected to the bottom end of the high-temperature incineration chamber 33 through the flue gas diversion chamber 12. The bottom of the flue gas diversion cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com