Production method of oxygen-free high-purity cadmium powder

A production method and high-purity technology are applied in the production field of oxygen-free high-purity cadmium powder, which can solve the problems of unguaranteed personnel safety, difficult operation, complicated equipment, etc., so as to reduce the labor intensity of personnel and improve the quality of the operating environment. , the effect of improving quality uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

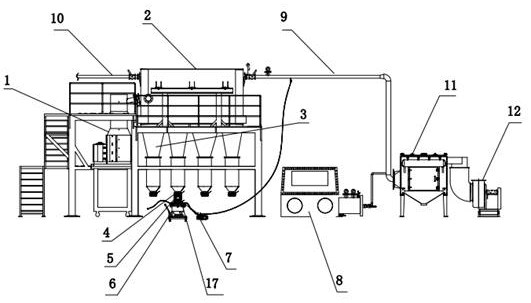

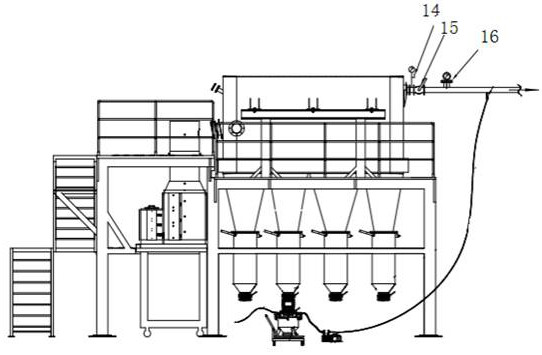

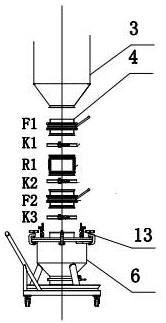

[0026] This embodiment discloses a method for producing oxygen-free high-purity cadmium powder, and provides a production system for oxygen-free high-purity cadmium powder. Its structural diagram is as follows figure 1 As shown, it includes a sublimation furnace evaporation tank 1 for heating and sublimating materials, a condenser 2, a material collector 3, an air intake pipe assembly 10, an exhaust fan 12, a sealing connection part 5, a material receiving tank 6 and a vacuum pump 7; The condenser 2 includes a condenser body and a condensing part for cooling the condenser body (specifically, it may be a cooling water jacket, and by turning on the circulation pump, water enters the cooling water jacket to achieve cooling), the condenser The upper part of the body is provided with a feed port, an air inlet and an exhaust port, and the bottom of the condenser body is provided with a discharge port. The gas pipeline assembly 10 is connected, the air inlet pipeline assembly 10 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com