A Tool Change Monitoring Method Based on Extended Kalman Filter and Cutting Force Model

A technology to expand Kalman and cutting force, applied in the direction of measuring/indicating equipment, metal processing equipment, metal processing machinery parts, etc., can solve the problem of inability to monitor tool wear on-line in real time, and reduce the loss of unqualified workpiece accuracy, The effect of reducing production costs and reducing cutting errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

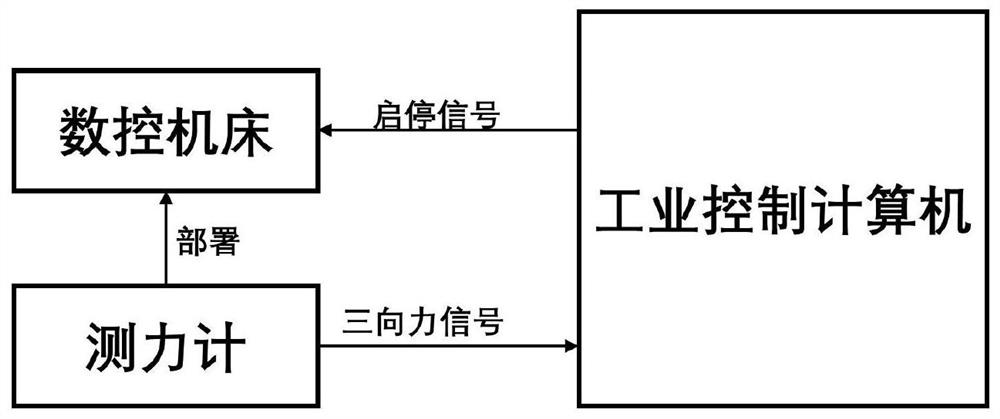

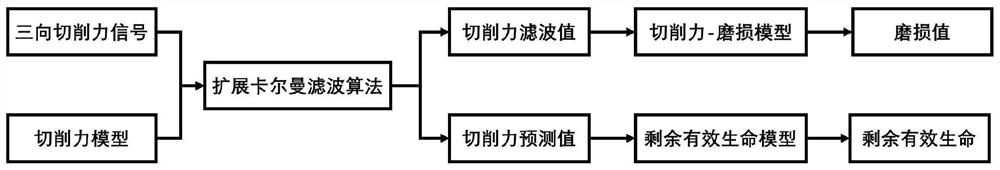

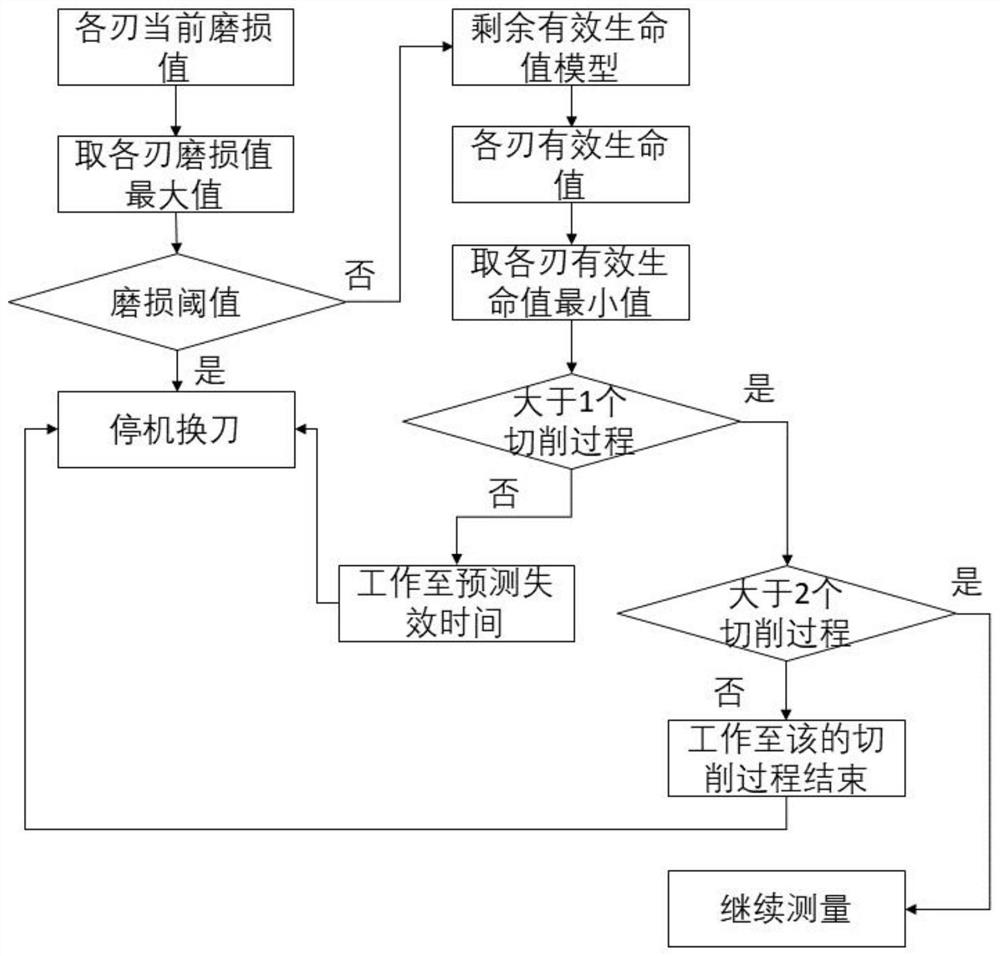

[0040] In this embodiment, a tool change monitoring method based on extended Kalman filter and cutting force model is a high-precision, real-time tool diagnosis and prediction system that combines mechanism models and advanced data processing algorithms, such as figure 1 As shown, including: CNC machine tools, dynamometers, industrial computers and intelligent algorithms:

[0041] In this embodiment, the CNC machine tool adopts a Roder TEC vertical milling machine, which includes a bus interface and a sensor bracket. The dynamometer is installed on the sensor bracket, and the cutting force signal is obtained in real time when the milling machine processes the workpiece. Through the bus interface, the Modbus communication protocol is used to interact with the industrial computer. The industrial computer calculates through the intelligent algorithm that when the tool wear reaches or is about to reach the wear threshold, it controls the CNC machine tool to stop and change the tool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com