Electronic packaging heat-conducting double-sided adhesive tape and preparation method thereof

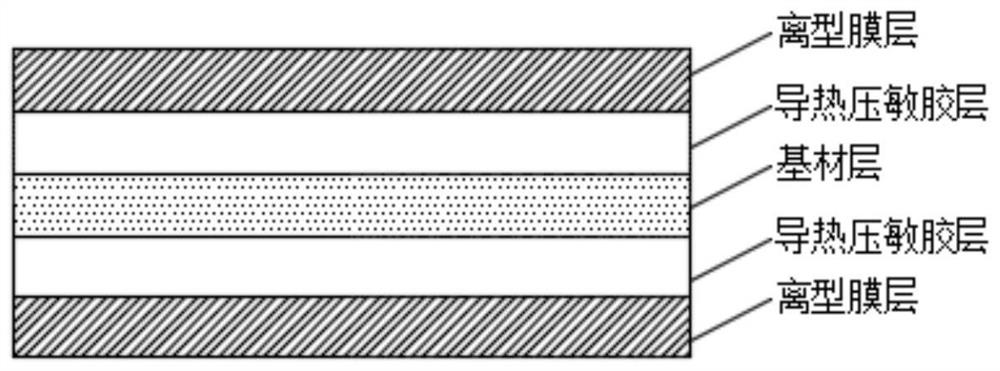

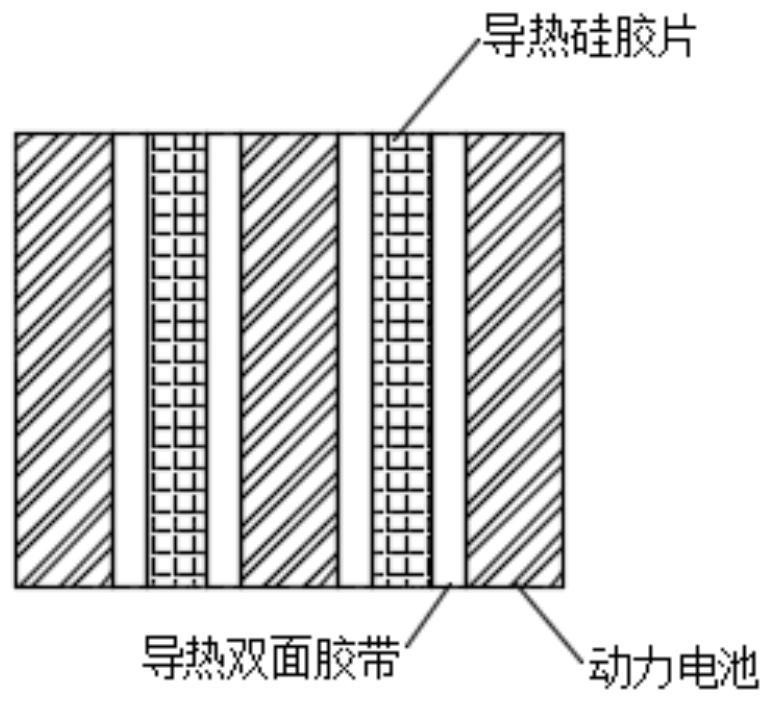

A double-sided adhesive tape and electronic packaging technology, which is applied in the direction of adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of affecting heat dissipation effect and low viscosity of heat-conducting silicone sheets, so as to make up for the lack of viscosity and cost. The effect of low cost and good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

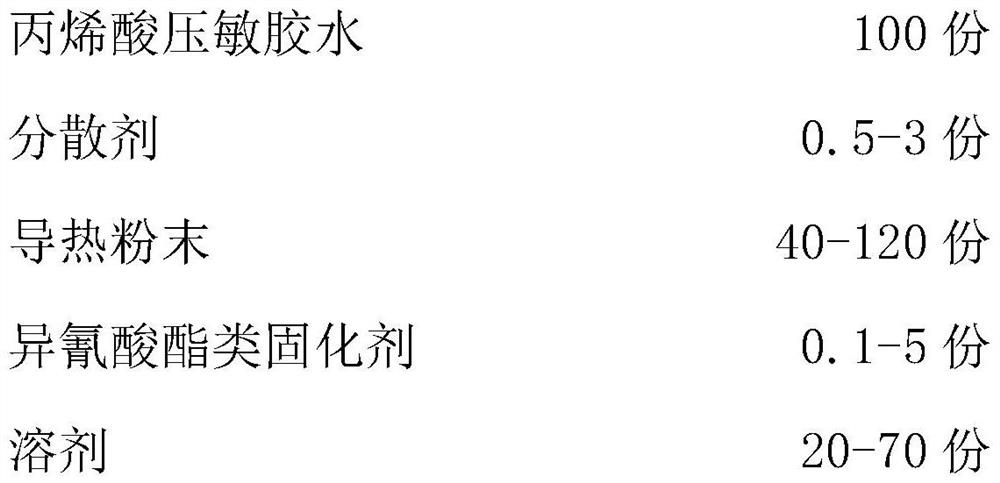

[0036] 1) Add 40 parts of boron nitride powder to 20 parts of ethyl acetate solvent, and soak for 2 hours to fully wet the boron nitride powder;

[0037] 2) After diluting 0.5 part of dispersant with ethyl acetate, add it to 100 parts of acrylic pressure-sensitive adhesive, stir for 5 minutes, and mix well to obtain acrylic pressure-sensitive adhesive glue with dispersant;

[0038] 3) Add the fully wetted boron nitride powder into the acrylic pressure-sensitive adhesive with dispersant, increase the speed of the mixer, and mix the materials evenly;

[0039] 4) Dissolve 0.5 part of isocyanate curing agent in ethyl acetate, add to the material in step 3), continue to stir and mix evenly, and filter the evenly mixed material through a 200-mesh filter to obtain heat-conducting pressure-sensitive adhesive glue;

[0040] 5) After the heat-conducting pressure-sensitive adhesive is left to remove air bubbles or removed in a vacuum, it is coated on the release film layer with a coating...

Embodiment 2

[0046] 1) Add 80 parts of boron nitride powder into 40 parts of ethyl acetate solvent and soak for 2 hours to fully wet the boron nitride powder;

[0047] 2) After diluting 1 part of dispersant with ethyl acetate, add it to 100 parts of acrylic pressure-sensitive adhesive, stir for 10 minutes, and mix well to obtain acrylic pressure-sensitive adhesive glue with dispersant;

[0048] 3) Add the fully wetted boron nitride powder into the acrylic pressure-sensitive adhesive with dispersant, increase the speed of the mixer, and mix the materials evenly;

[0049] 4) Dissolve 3 parts of isocyanate curing agent in ethyl acetate, add to the material in step 3), continue to stir and mix evenly, and filter the evenly mixed material through a 200-mesh filter to obtain heat-conducting pressure-sensitive adhesive glue;

[0050] 5) After the heat-conducting pressure-sensitive adhesive is left standing to remove air bubbles or vacuumed to remove air bubbles, it is coated on the release film l...

Embodiment 3

[0056] 1) Add 90 parts of boron nitride powder into 60 parts of ethyl acetate solvent, and soak for 1.5 hours to fully wet the boron nitride powder;

[0057] 2) After diluting 2 parts of dispersant with ethyl acetate, add it to 100 parts of acrylic pressure-sensitive adhesive, stir for 5 minutes, and mix well to obtain acrylic pressure-sensitive adhesive glue with dispersant;

[0058] 3) Add the fully wetted boron nitride powder into the acrylic pressure-sensitive adhesive with dispersant, increase the speed of the mixer, and mix the materials evenly;

[0059] 4) Dissolve 4 parts of isocyanate curing agent in ethyl acetate, add to the material in step 3), continue to stir and mix evenly, and filter the evenly mixed material through a 200-mesh filter to obtain heat-conducting pressure-sensitive adhesive glue;

[0060] 5) After the heat-conducting pressure-sensitive adhesive is left standing to remove air bubbles or vacuumed to remove air bubbles, it is coated on the release film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com