Acid discharge process for Hu-sheep mutton

A lake mutton and technology technology, applied in meat processing equipment, processed meat, dried and preserved meat/fish, etc., can solve the problems of affecting the taste of the product, uneven oil injection, large water evaporation, etc., to prevent accidental injury to the staff , reduce bacterial growth, reduce the effect of bacterial growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A process for souring Hu mutton, comprising:

[0039] (1) Vacuum bloodletting: When the Hu sheep did not respond, they were stunned by vacuum bloodletting to death, and the sheep were massaged from time to time. Corona before the reaction, and massage the Hu sheep to keep the meat compact and tender;

[0040] (2) Preliminary deacidification, hang the dead Hu sheep in the deacidification room for preliminary deacidification, control the temperature of the deacidification room at 0-4°C, control the wind speed at 0.25-0.5m / s, and control the humidity at 85-90 %, deacidification for 3-5 hours;

[0041] (3), oil spraying treatment: the mutton of preliminary deacidification is added in the oil spraying device, sprayed, air-dried, and the temperature is controlled at 0-4 ° C in the said oil spraying device;

[0042] (4) Second acid discharge: Wrap the mutton with oil film tightly with plastic wrap, then tie the two ends of the plastic wrap tightly, and then hang it in the ac...

Embodiment 2

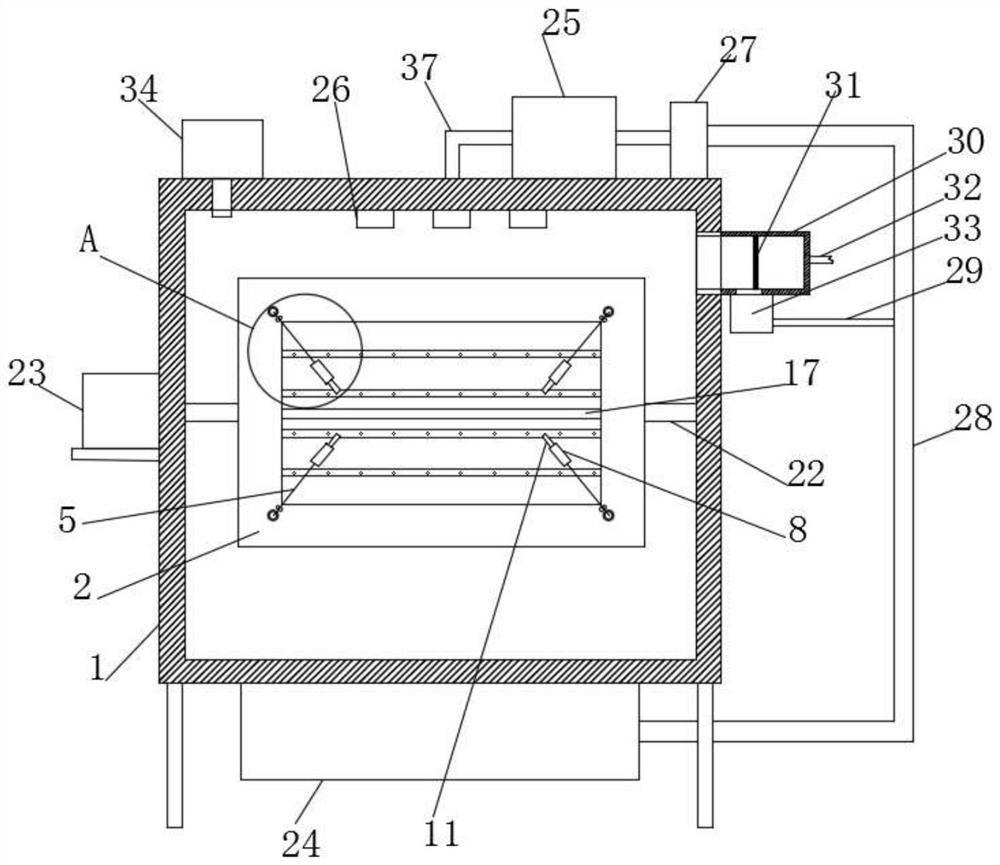

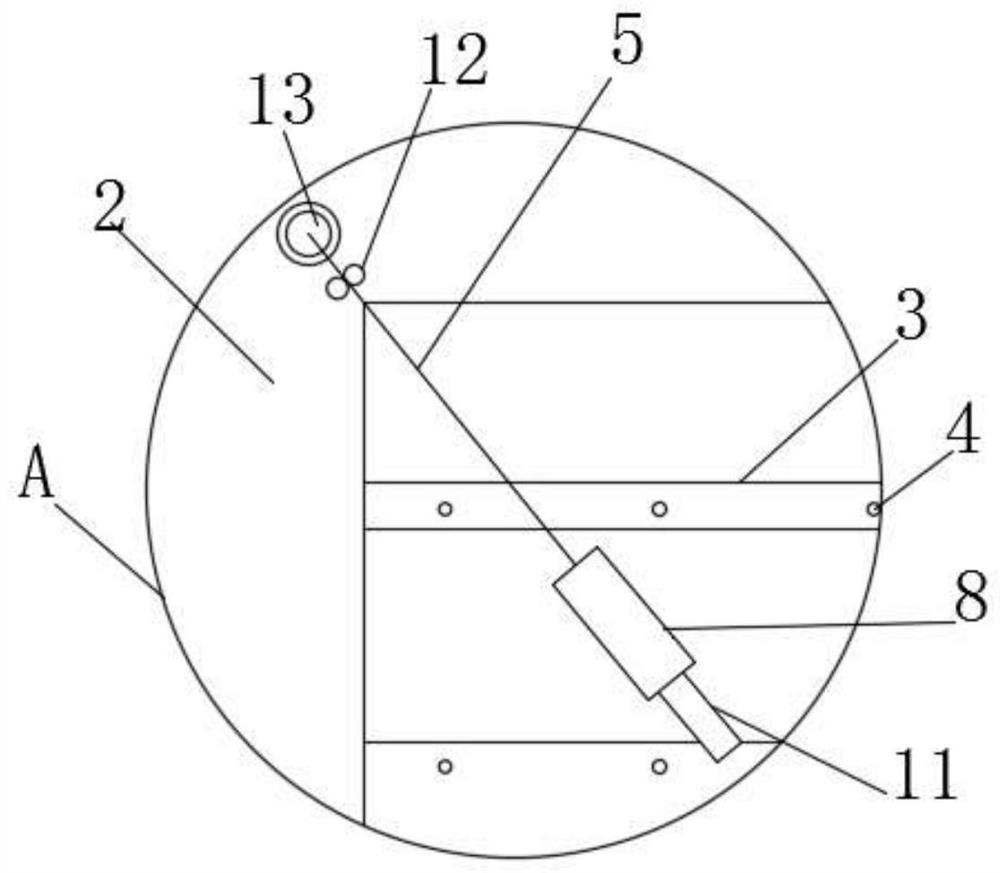

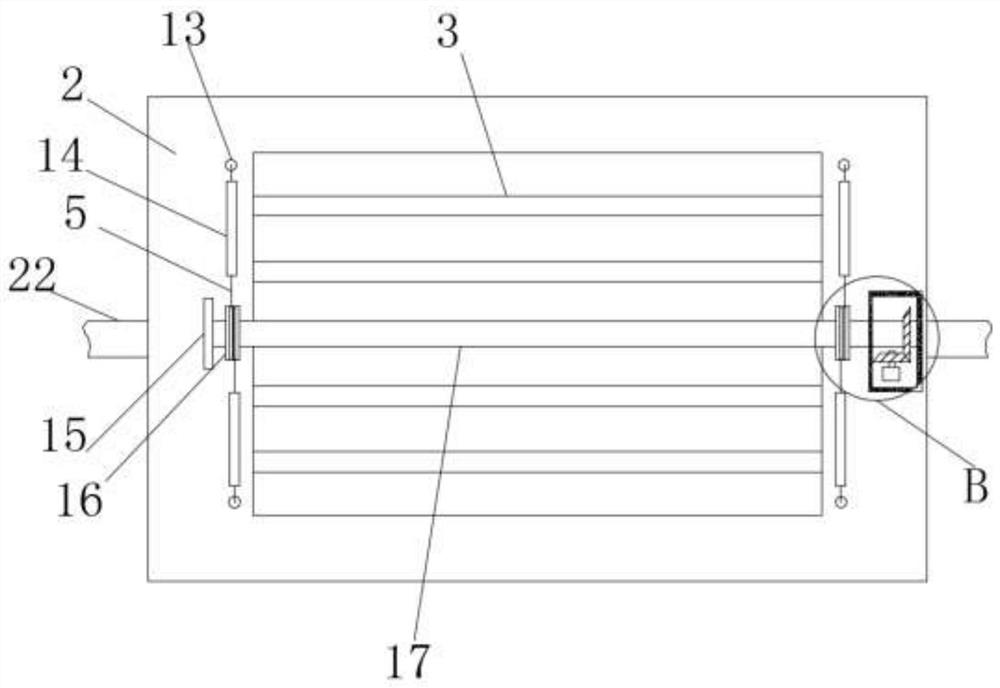

[0048] see Figure 1-7 As shown, on the basis of Embodiment 1, the fuel injection device includes a box body 1, the upper end of the box body 1 is provided with a fuel injection mechanism, and the middle part of the box body 1 is provided with a back-shaped plate 2, and the back-shaped The left and right ends of the plate 2 are connected to the inner wall of the box body 1 through the rotating shaft 22. The second motor 23 that drives the rotating shaft 22 to rotate is arranged on the outside of the box body 1. The two ends of the take-up shaft 17 are rotatably connected with the support plate 15 and the protective shell 18 fixedly arranged on the back-shaped plate 2, and a driving mechanism for driving the take-up shaft 17 to rotate is arranged in the box body 1, and the two ends of the take-up shaft 17 are The symmetrical sleeve is provided with a take-up wheel 16, and the four corners of the return-shaped plate 2 are provided with a fixing mechanism;

[0049] The fixing me...

Embodiment 3

[0057] see figure 1 As shown, on the basis of Embodiment 1, the upper end of the box body 1 is provided with a cooling fan 34 communicating with the inside of the box body 1, and the side wall of the box body 1 is provided with an air outlet, and the air outlet is provided with a separation shell 30, the middle part of the separation shell 30 is provided with a filter screen 31, the lower end of the separation shell 30 is provided with an internally connected oil collection tank 33, the oil collection tank 33 is located below the filter screen 31, and the right end of the separation shell 30 is provided with an air outlet pipe 32.

[0058] Specifically, the cold air blower 34 blows cold air to keep the temperature in the box body 1 low. The cold air enters the separation shell 30 with a part of oil, and the filter screen 31 filters the oil mixed in the wind. Due to gravity, the oil flows from the filter screen 31. Entering the oil collection tank 33, the clean cold air is blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com