Cleaning brush roller used in TFT-LCD display screen production and manufacturing method thereof

A technology of brush roller and display screen, which is applied in the direction of brushes, applications, brush bodies, etc., can solve the problems of bristle distribution density gap, failure to reach cleaning accuracy, loss, etc., and achieve reasonable structural design, improved quality, and reduced The effect of small swings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] See attached picture.

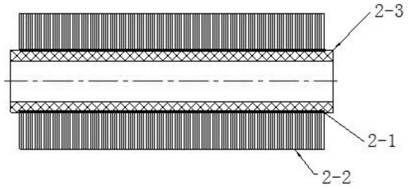

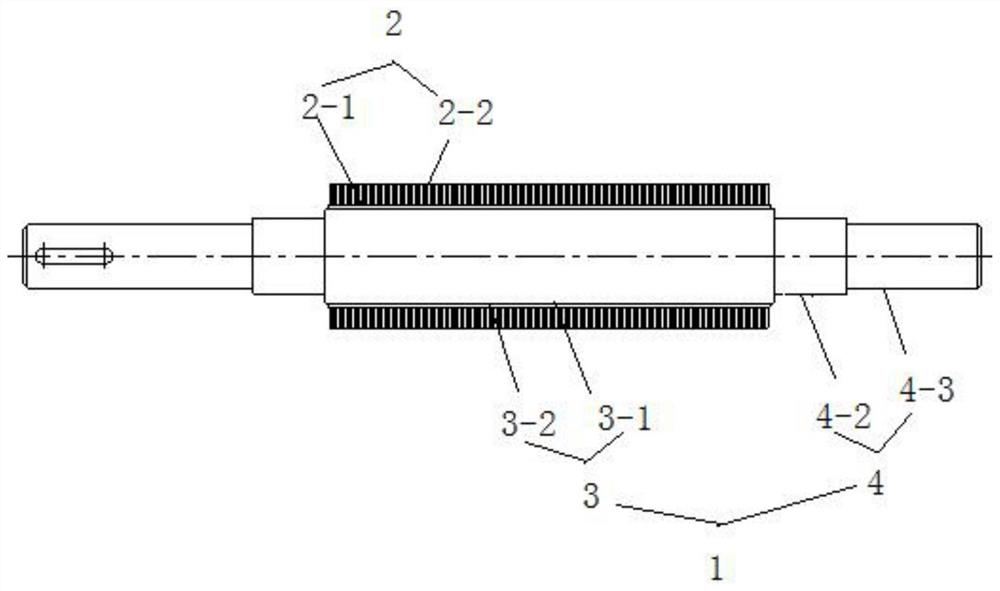

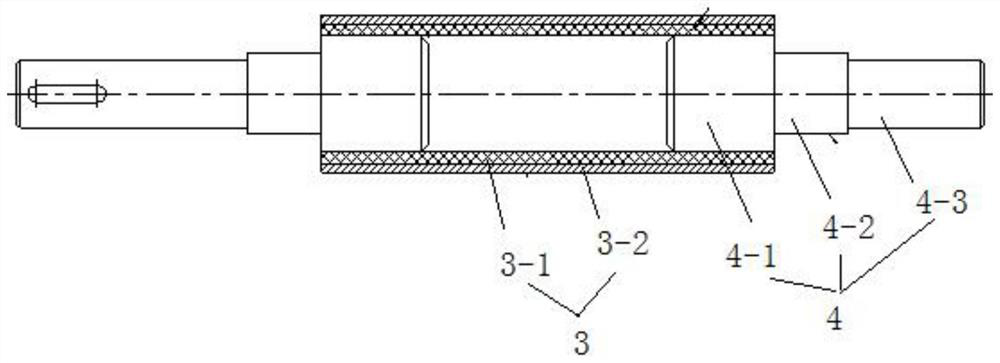

[0034] A cleaning brush roller used in the production of TFT-LCD display screens, including a brush shaft 1 and a brush cover 2, the brush shaft 1 includes a middle shaft body 3, the middle shaft body 3 has a double-layer structure, and its outer layer is thin-walled The structure of the tube body 3-1, the inner wall of the thin-walled tube body 3-1 is inlaid with carbon fiber tubes 3-2, the two ends of the thin-walled tube body 3-1 are equipped with end fixing shafts 4, and the brush cover 2 includes a brush belt 2- 1. The brush belt 2-1 is irregularly woven with ultra-fine brush filaments 2-2, and the ultra-fine brush filaments 2-2 use nylon bristles with a diameter of 0.05mm. The ultra-fine brush wire 2-2 is woven onto the belt by a weaving machine. The weaving density requires about 10,000 bristles to be evenly distributed in 1 square meter. The ultra-fine brush wire is irregularly fixed on the brush belt by weaving. It increases the distrib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com