Sandwich moxa cone semi-forming pre-embedding production device and production method

A production device and a semi-molded technology, applied in the field of moxibustion, can solve the problems of flying mugwort powder, hollow columnar shape, single odor and efficacy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

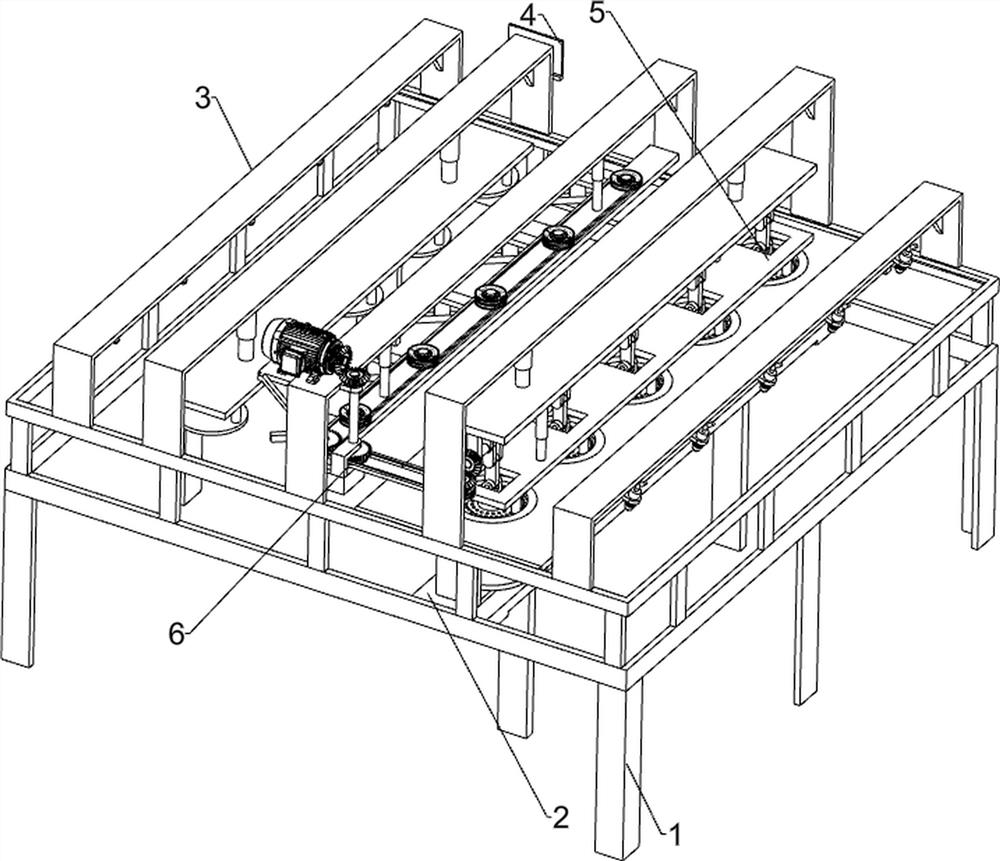

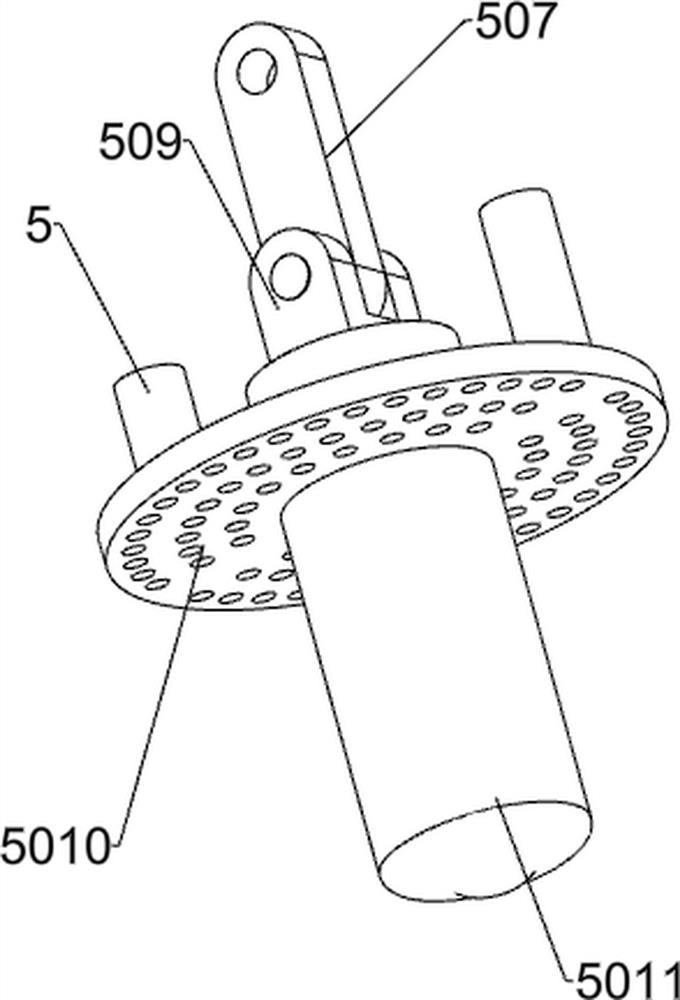

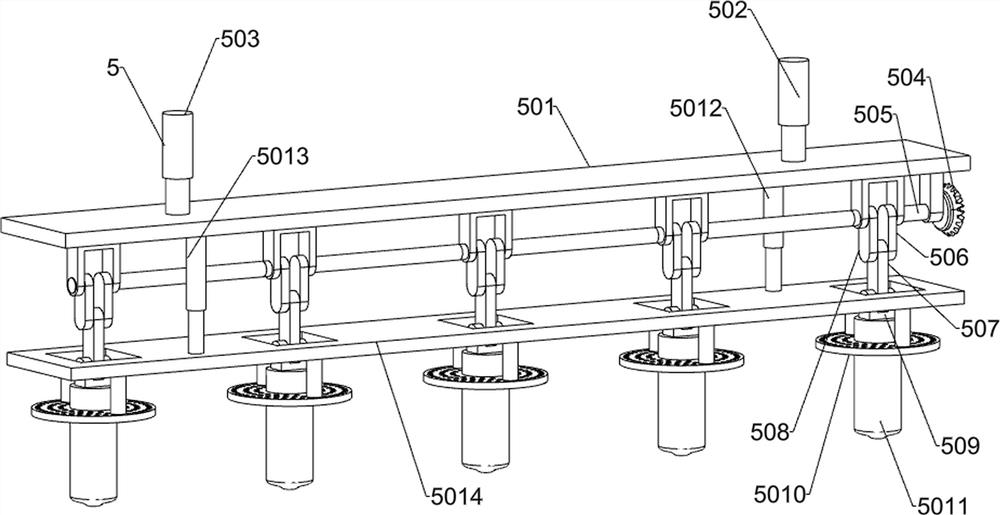

[0035] A kind of sandwich moxa column semi-formed pre-embedded production device, such as Figure 1-10 As shown, it includes an underframe 1, a first support plate 2, a transfer mechanism 3, a control panel 4, a dust-free decompression semi-forming mechanism 5 and a scraping mechanism 6; the underframe 1 and the first support plate 2 are fixed connection; the base frame 1 is connected with the transfer mechanism 3; the transfer mechanism 3 is fixedly connected with the control panel 4; the transfer mechanism 3 is connected with the dust-free decompression semi-forming mechanism 5; the transfer mechanism 3 is connected with the scraping mechanism 6 phases are connected; the dust-free decompression semi-forming mechanism 5 is connected with the scraping mechanism 6.

[0036] Working principle: When in use, first place the bottom frame 1 on the level ground, then connect the external power supply, connect the powder inlet pipeline, and at the same time place a conveyor belt in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com