Base band winding device as well as polytetrafluoroethylene microporous membrane and preparation method thereof

A technology of polytetrafluoroethylene and winding device, which is applied in the direction of chemical instruments and methods, membrane technology, flat products, etc., and can solve problems such as poor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

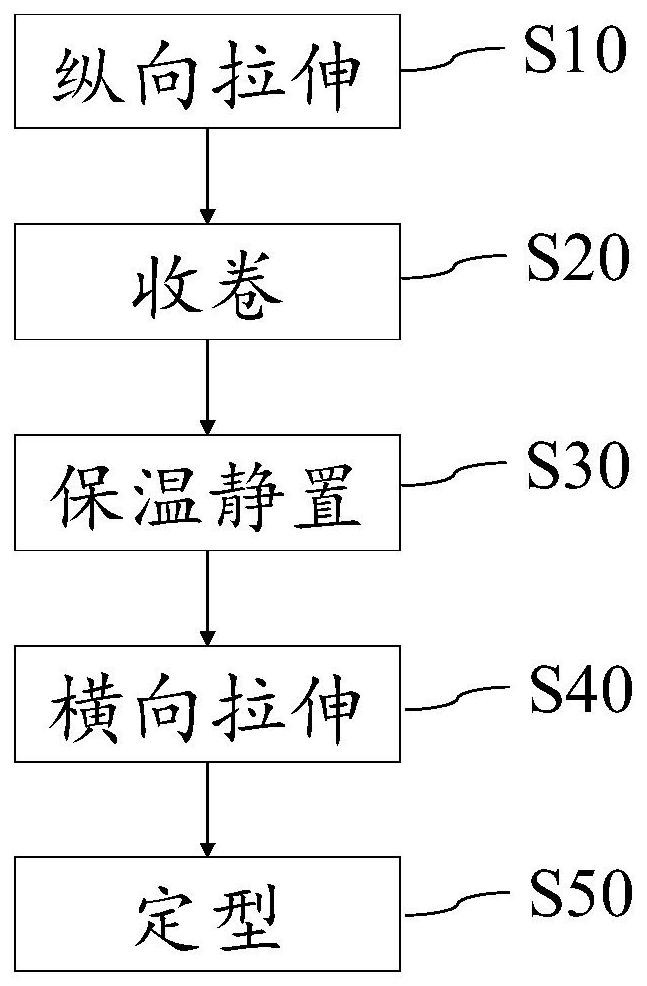

[0089] The preparation method of polytetrafluoroethylene microporous membrane in the present embodiment is:

[0090] (1) Longitudinal stretching: the polytetrafluoroethylene base tape with a thickness of 100 μm was stretched longitudinally in an oven at 300° C. to obtain a degreased base tape.

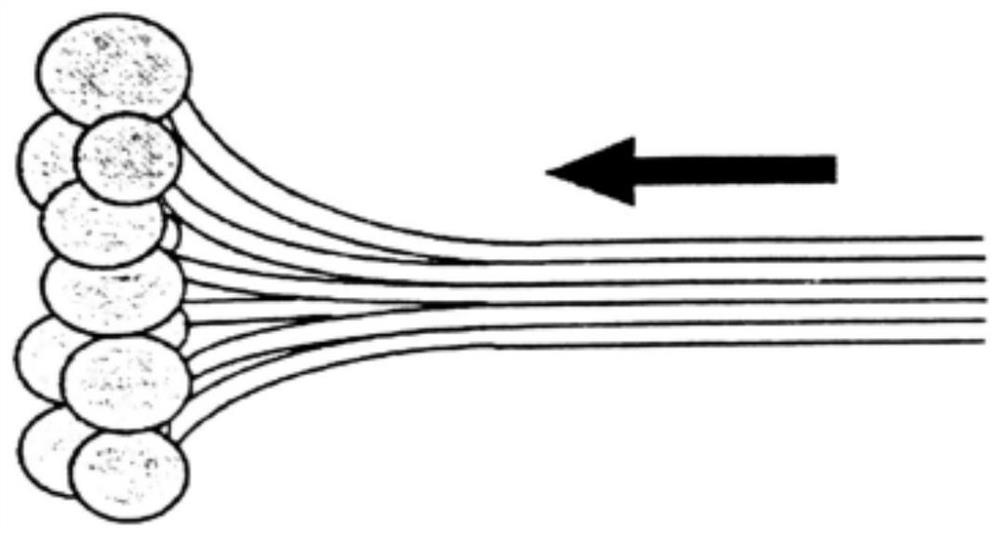

[0091] (2) Winding: the degreased base tape obtained in step (1) is wound on an olive-shaped base tape winding device 10 to obtain a wound base tape. Wherein, in the base tape winding device 10 , the included angle between the generatrix of the winding roller 100 and the axis is 30°. The first included angle of the rolled lines in the first direction in the rolled line area 130 is 15°, and the second included angle of the rolled lines in the second direction is 15°.

[0092] (3) Stand still and keep warm: put the winding base tape obtained in step (2) into an oven to stand still, and perform heat preservation treatment to obtain a pre-stretched base tape. Specifically, keep the tempe...

Embodiment 2

[0097] The preparation method of polytetrafluoroethylene microporous membrane in the present embodiment is:

[0098] (1) Longitudinal stretching: the polytetrafluoroethylene base tape with a thickness of 100 μm was stretched longitudinally in an oven at 300° C. to obtain a degreased base tape.

[0099] (2) Winding: the degreased base tape obtained in step (2) is wound on an olive-shaped base tape winding device 10 to obtain a wound base tape. Wherein, in the base tape winding device 10 , the included angle between the generatrix of the winding roller 100 and the axis is 30°. The first included angle of the rolled lines in the first direction in the rolled line area 130 is 85°, and the second included angle of the rolled lines in the second direction is 85°.

[0100] (3) Stand still and keep warm: put the winding base tape obtained in step (3) into an oven to stand still, and perform heat preservation treatment to obtain a pre-stretched base tape. Specifically, keep the tempe...

Embodiment 3

[0105] The preparation method of polytetrafluoroethylene microporous membrane in the present embodiment is:

[0106] (1) Longitudinal stretching: The polytetrafluoroethylene base tape with a thickness of 100 μm was stretched longitudinally in an oven at 300° C. to obtain a degreased base tape.

[0107] (2) Winding: the degreased base tape obtained in step (1) is wound on an olive-shaped base tape winding device 10 to obtain a wound base tape. Wherein, in the base tape winding device 10 , the included angle between the generatrix of the winding roller 100 and the axis is 15°. The first included angle of the rolled lines in the first direction in the rolled line area 130 is 50°, and the second included angle of the rolled lines in the second direction is 50°.

[0108] (3) Stand still and keep warm: put the winding base tape obtained in step (2) into an oven to stand still, and perform heat preservation treatment to obtain a pre-stretched base tape. Specifically, at a temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com