Combined transmutation glaze, combined transmutation glaze porcelain and preparation method of combined transmutation glaze porcelain

A technology of kiln changing glaze and glaze, applied in the field of ceramics, can solve the problems of lack of color and diverse textures, and achieve the effects of diverse surface textures, enhanced plasticity, and increased viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

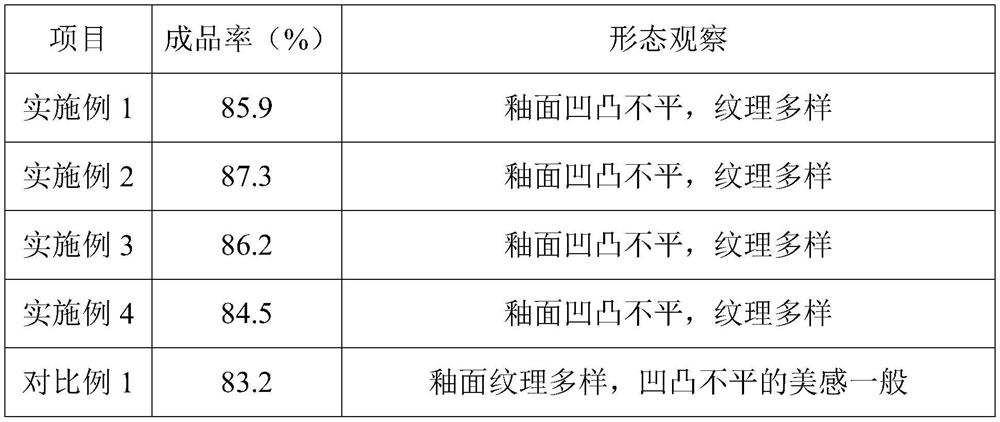

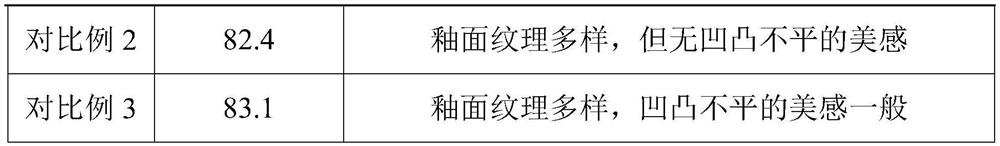

Examples

Embodiment 1

[0040] A combined kiln-changing glaze, comprising a base glaze, a first intermediate glaze, a second intermediate glaze and a top glaze, in parts by weight:

[0041] The bottom glaze glaze material comprises the following components: 65 parts of nepheline orthoclase, 5 parts of dolomite, 4 parts of limestone, 10 parts of china clay, and 5 parts of bentonite;

[0042] The first intermediate glaze comprises the following components: 65 parts of nepheline orthoclase, 5 parts of dolomite, 4 parts of limestone, 10 parts of zinc oxide, 5 parts of bentonite, 10 parts of quartz, and 10 parts of colorant;

[0043] The second intermediate glaze comprises the following components: 60 parts of nepheline orthoclase, 10 parts of dolomite, 2 parts of zinc oxide, 5 parts of bentonite, 10 parts of rutile, and 10 parts of ilmenite;

[0044] The surface glaze includes the following components: 70 parts of nepheline orthoclase, 10 parts of dolomite, 3 parts of zinc oxide, 5 parts of bentonite and 5...

Embodiment 2

[0056] A combined kiln-changing glaze, comprising a base glaze, a first intermediate glaze, a second intermediate glaze and a top glaze, in parts by weight:

[0057] The bottom glaze glaze material comprises the following components: 70 parts of nepheline orthoclase, 4 parts of dolomite, 3 parts of limestone, 8 parts of china clay, and 4 parts of bentonite;

[0058] The first intermediate glaze comprises the following components: 70 parts of nepheline orthoclase, 4 parts of dolomite, 3 parts of limestone, 8 parts of zinc oxide, 4 parts of bentonite, 8 parts of quartz, and 8 parts of colorant;

[0059] The second intermediate glaze comprises the following components: 65 parts of nepheline orthoclase, 8 parts of dolomite, 1.5 parts of zinc oxide, 4 parts of bentonite, 8 parts of rutile, and 8 parts of ilmenite;

[0060] The surface glaze includes the following components: 75 parts of nepheline orthoclase, 8 parts of dolomite, 2.5 parts of zinc oxide, 4 parts of bentonite and 4 p...

Embodiment 3

[0072] A combined kiln-changing glaze, comprising a base glaze, a first intermediate glaze, a second intermediate glaze and a top glaze, in parts by weight:

[0073] The underglaze glaze comprises the following components: 75 parts of nepheline orthoclase, 3 parts of dolomite, 2 parts of limestone, 5 parts of china clay, and 3 parts of bentonite;

[0074] The first intermediate glaze comprises the following components: 75 parts of nepheline orthoclase, 3 parts of dolomite, 2 parts of limestone, 5 parts of zinc oxide, 3 parts of bentonite, 5 parts of quartz, and 5 parts of colorant;

[0075] The second intermediate glaze comprises the following components: 70 parts of nepheline orthoclase, 5 parts of dolomite, 1 part of zinc oxide, 3 parts of bentonite, 5 parts of rutile, and 5 parts of ilmenite;

[0076] The surface glaze includes the following components: 80 parts of nepheline orthoclase, 5 parts of dolomite, 2 parts of zinc oxide, 3 parts of bentonite and 3 parts of quartz. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com