Impregnation rotary spinning equipment for preparing gelatin/cellulose 3D scaffold for cell culture meat production

A technology of cell culture and rotary spinning, which is applied in the production of complete sets of equipment for artificial threads, cell culture supports/coatings, cellulose/protein conjugated artificial filaments, etc., which can solve the problem of unsuitable 3D scaffolds and limit wide application , cytotoxicity and other issues, to achieve the effect of biocompatibility, wide source and high biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] 1. The assembly of the spinning equipment:

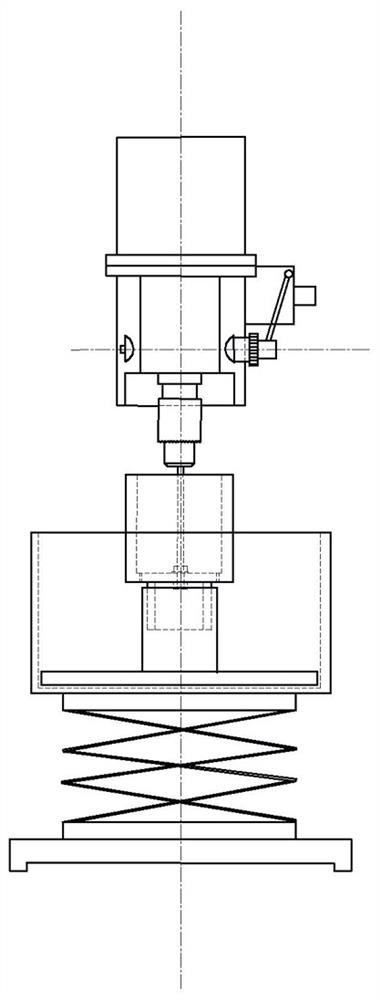

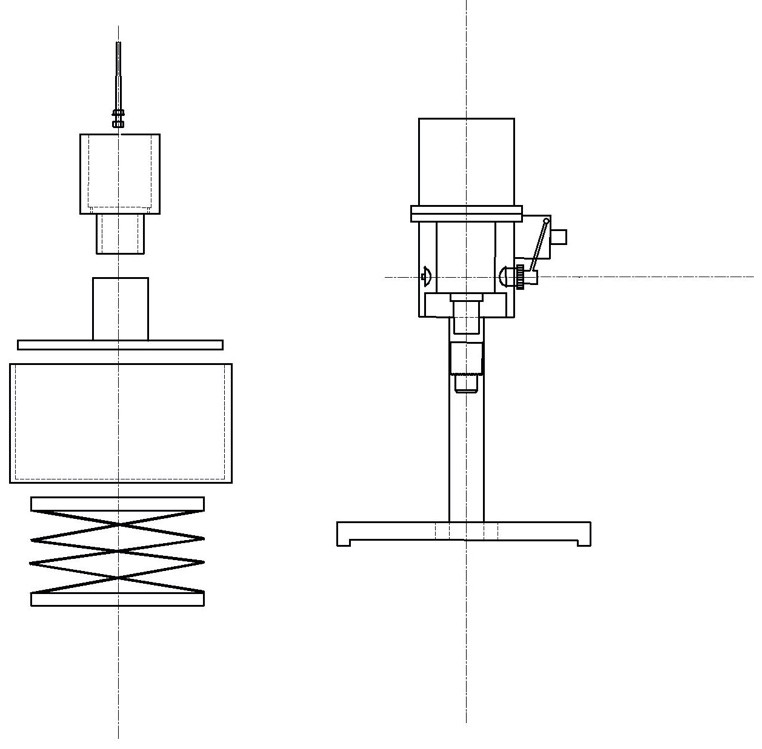

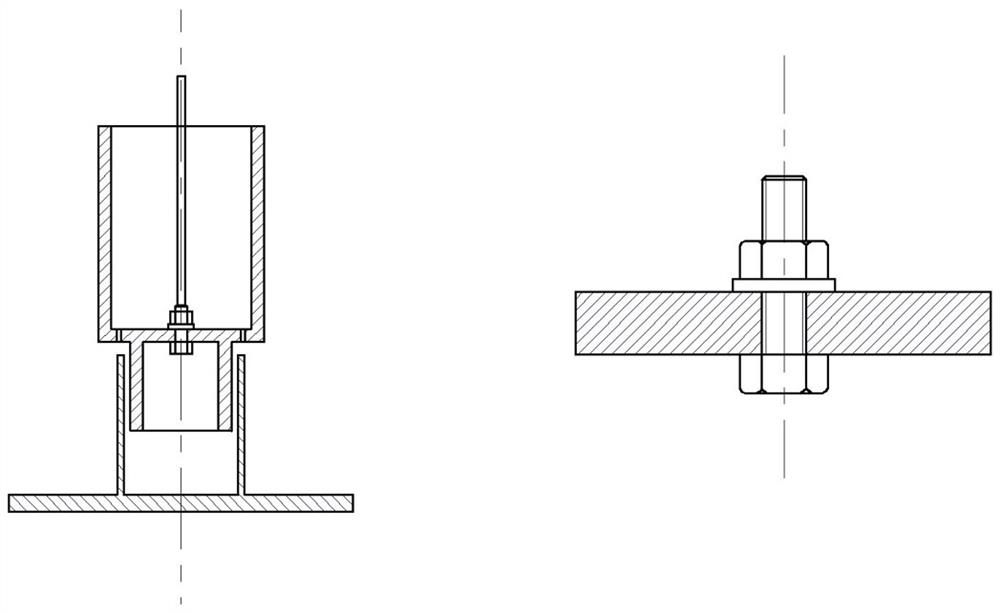

[0029] The dip spinning equipment includes a rotating motor (1), a sample reservoir (2) with fine holes on the edge of the bottom surface, a cylindrical inverted "T" collector (3), a collection cylinder (4) and a height adjustment device (5) .

[0030] The dip spinning equipment is in accordance with figure 1 Assemble, specifically: electrify the rotating motor, connect the lower end interface of the motor with the sample storage device through the transmission steel shaft, and then put the cylindrical inverted "T" shaped collector into the collection cylinder, between the collection cylinder and the sample storage device The appropriate distance is adjusted by the height adjustment device.

[0031] 2. The gelatin / cellulose 3D scaffold prepared by using the impregnated rotary spinning equipment: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com