Oil field wellhead device with automatic chemical adding mechanism

A technology of automatic dosing and wellhead devices, which is applied in the direction of wellbore/well components, production fluid, earthwork drilling and production, etc. It can solve the problems of no dosing mechanism, time-consuming and laborious operation, and inability to do automatic dosing, etc. To achieve the effect of improving the operation effect and operation efficiency, and the operation is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

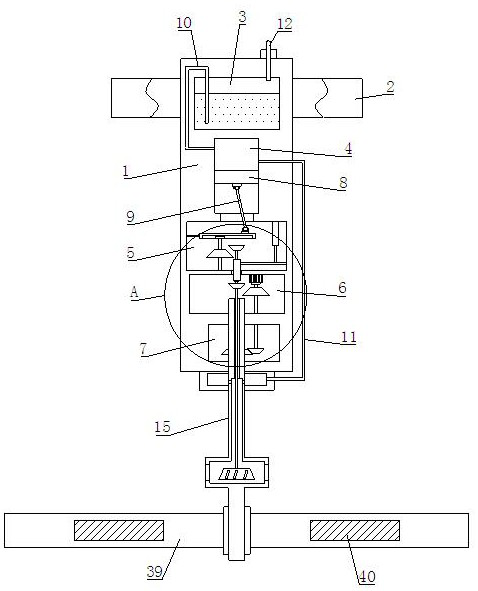

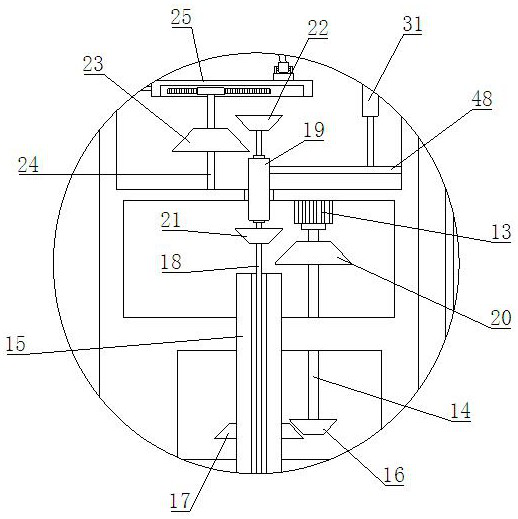

[0032] Such as Figure 1-6 As shown, the present invention proposes an oilfield wellhead device with an automatic dosing mechanism, comprising a medicine storage tank body 1, a wellhead casing 2, a medicine storage chamber 3 and a dosing pipe joint 12, and the wellhead casing 2 is fixedly installed At the wellhead of the oilfield, the medicine storage tank body 1 is fixedly installed on the wellhead casing 2 by bolts and extends into the oilfield wellhead. The inside of the medicine storage tank body 1 is provided with a medicine storage chamber 3, which stores medicine The dosing pipe joint 12 is arranged on the medicine storage tank body 1 and communicates with the medicine storage chamber 3. The medicine dosing pipe joint 12 is used to connect the dosing pipe, and the medicine liquid is added to the medicine storage chamber 3 through the dosing pipe. The drug storage tank body 1 is provided with a medicine discharge chamber 4, and a piston 8 is slidably arranged in the medi...

Embodiment 2

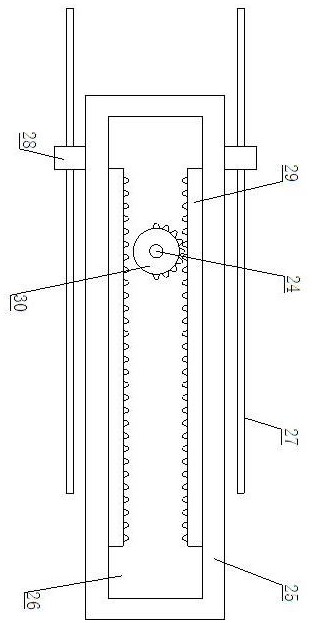

[0037] Such as Figure 5 As shown, this embodiment is basically the same as Embodiment 1. Preferably, multiple sets of second guide rods 46 are fixedly installed in the groove 41 by bolts, and the movable plate 43 is slidably connected with the second guide rods 46, and the movable plate 43 is along the The second guide rod 46 slides; the second guide rod 46 is sleeved with a second spring 47, the second spring 47 is a compression spring, the second spring 47 connects the movable plate 43 and the stirring plate 39, and the movable plate 43 is pressed and constantly squeezed. Press the second spring 47, and the second spring 47 plays a buffering role, which helps to avoid quickly hitting the pressure sensor 44 and causing damage to it; the side of the movable plate 43 facing the pressure sensor 44 is fixed with an extruding ball 45 by bolts, When the movable plate 43 slides in the groove 41, it drives the extrusion ball 45 to move, and the extrusion ball 45 squeezes the pressur...

Embodiment 3

[0039] Such as Figure 7-8 As shown, this embodiment is basically the same as Embodiment 1. Preferably, a drug infusion channel 35 is vertically opened in the rotating column 15, and the drug infusion channel 35 transports the drug liquid, and the bottom of the drug storage tank body 1 is fixed by bolts. A medicine collection box 33 is installed, and the other end of the medicine discharge pipe 11 communicates with the medicine collection box 33, and the medicine discharge pipe 11 transports the medicine liquid to the medicine collection box 33, and the medicine collection box 33 collects the medicine liquid; the rotating column 15 runs through The drug collecting box 33, and the rotating column 15 is provided with a drug inlet 34 connecting the drug collecting box 33 and the drug delivery channel 35, and the drug solution enters the drug delivery channel 35 through the drug inlet 34; the rotating column 15 is close to one end of the stirring plate 39 There is a drug discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com