Welding and cutting equipment with protection function and application method thereof

A technology of cutting equipment and protection function, applied in the field of welding and cutting equipment, can solve the problems of poor wideness, difficult adjustment of the placement position of parts, easy to produce unfavorable high temperature conditions, etc., to achieve the effect of improving cutting effect and improving wideness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

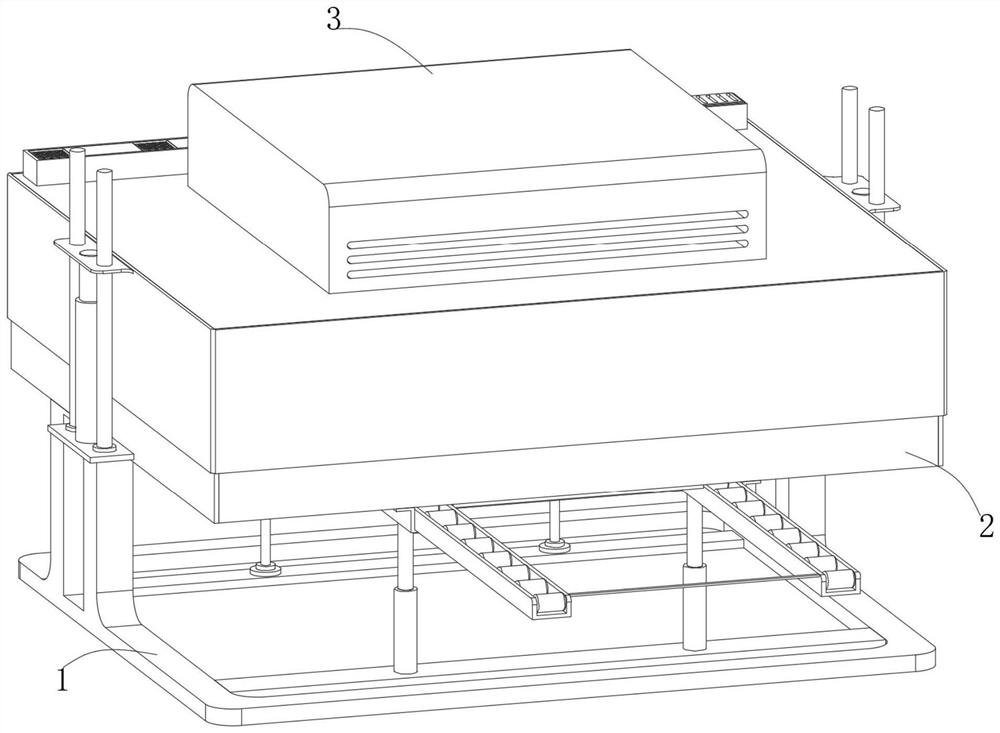

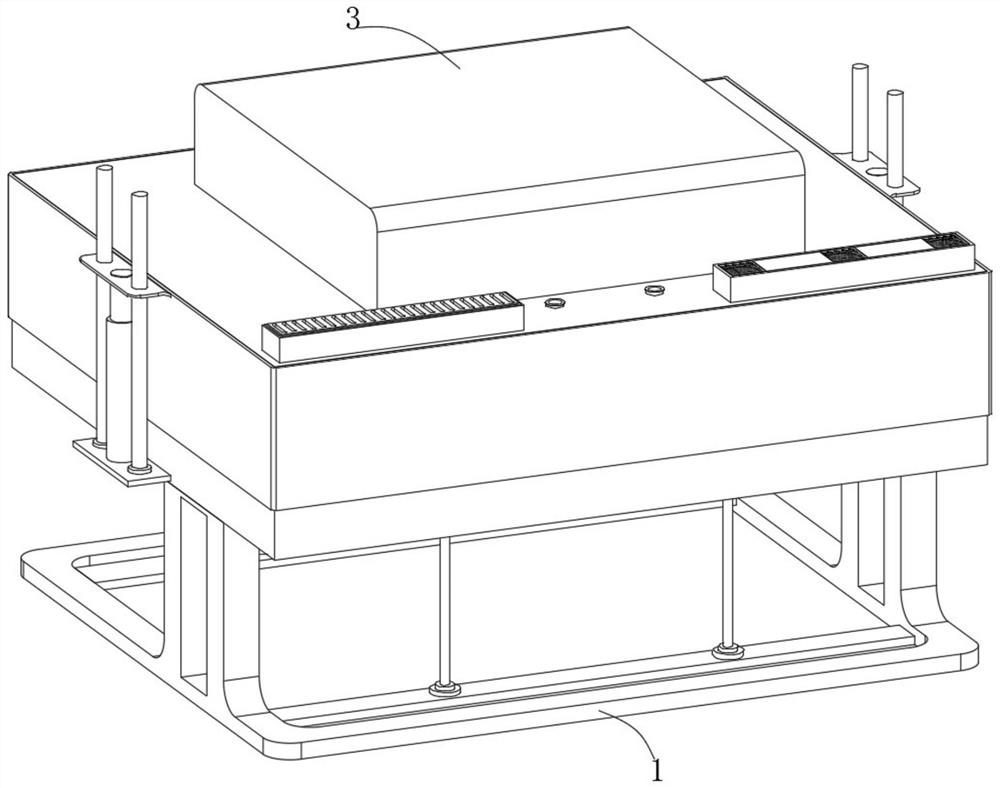

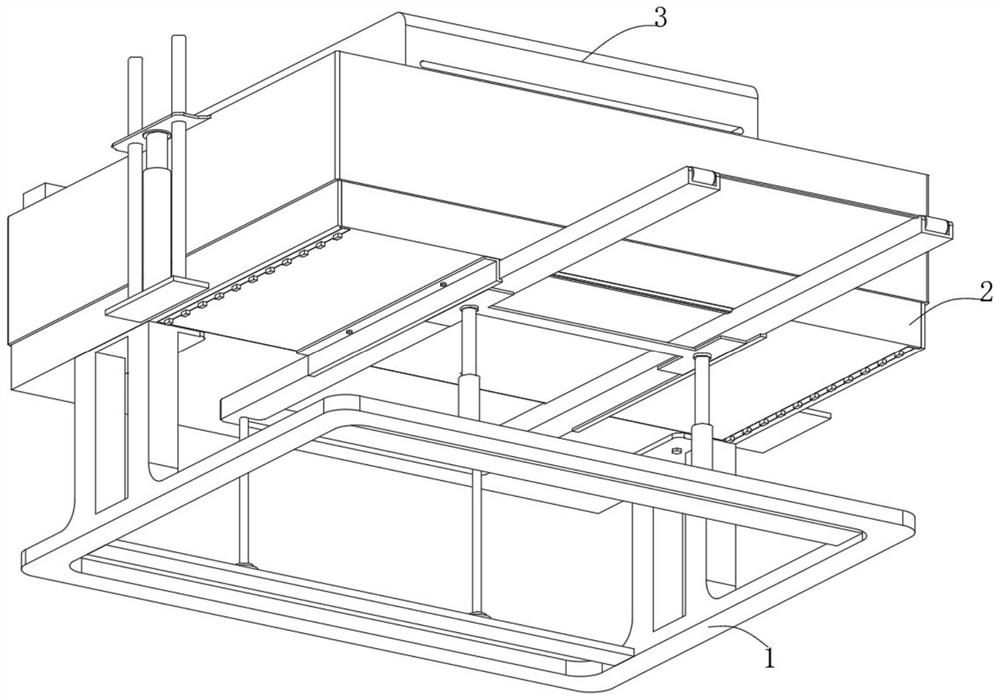

[0032] Embodiment one, with reference to Figure 1-9 : A welding and cutting equipment with protection function, comprising: a support mechanism 1, the support mechanism 1 includes a base 101, a bottom frame 102, two support parts and a lifting part, the establishment of the base 101 provides an installation basis for other functional parts of the equipment, The installation of other functional parts of the equipment is facilitated by the establishment of the bottom frame 102. The bottom frame 102 is fixedly connected to the top of the base 101, and the sound insulation frame 103 is fixedly connected inside the bottom frame 102. The establishment of the sound insulation frame 103 and the sound insulation board 202 can effectively prevent the equipment from The noise generated during actual use will have adverse effects on the operator. The two supporting parts are fixedly connected to the outer surfaces of both sides of the bottom frame 102, and the lifting part is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com