Carbon black loaded highly-ordered PtNi intermetallic compound, synthesis method and application thereof

A technology of intermetallic compounds and synthesis methods, applied in the field of nanomaterials, can solve problems such as insufficient kinetic diffusion, low phase transition temperature, and insufficient thermodynamic driving force, and achieve good electrocatalytic oxygen reduction activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention provides a kind of synthetic method that prepares carbon black loading highly ordered PtNi intermetallic compound by two-step heat treatment, comprises the following steps:

[0029] A) nickel salt, platinum salt and carbon black are dispersed in a solvent to obtain a suspension;

[0030] B) removing the solvent from the suspension and performing high-temperature annealing and low-temperature annealing in sequence to obtain a highly ordered PtNi intermetallic compound loaded with carbon black.

[0031] In the present invention, nickel salt, platinum salt and carbon black are firstly dispersed in a solvent to obtain a suspension. Wherein, the nickel salt is selected from NiCl 2 ·6H 2 O; the platinum salt is selected from H 2 PtCl 4 ·6H 2 O.

[0032] The molar ratio of the nickel salt to the platinum salt is 1.2-1.5:1, preferably 1.2:1, 1.3:1, 1.4:1, 1.5:1, or any value between 1.2-1.5:1.

Embodiment 1

[0054] a. 50g commercial carbon black BP2000, 14.7mg H 2 PtCl 4 ·6H 2 O and 10.2 mg NiCl 2 ·6H 2 O was mixed with 50mL absolute ethanol, soaked and stirred overnight, and the solvent was removed by a rotary evaporator to obtain a uniformly mixed precursor powder;

[0055] b. After drying the precursor powder in an oven, transfer it to a quartz crucible, put it into a tube furnace, and raise the powder precursor to 5°C / min under a protective atmosphere of 5% hydrogen and 95% argon. 1100°C, keep for 2h; then cool to 550°C for 30 minutes and keep for 12 hours, then naturally cool to room temperature to obtain a highly ordered PtNi intermetallic compound;

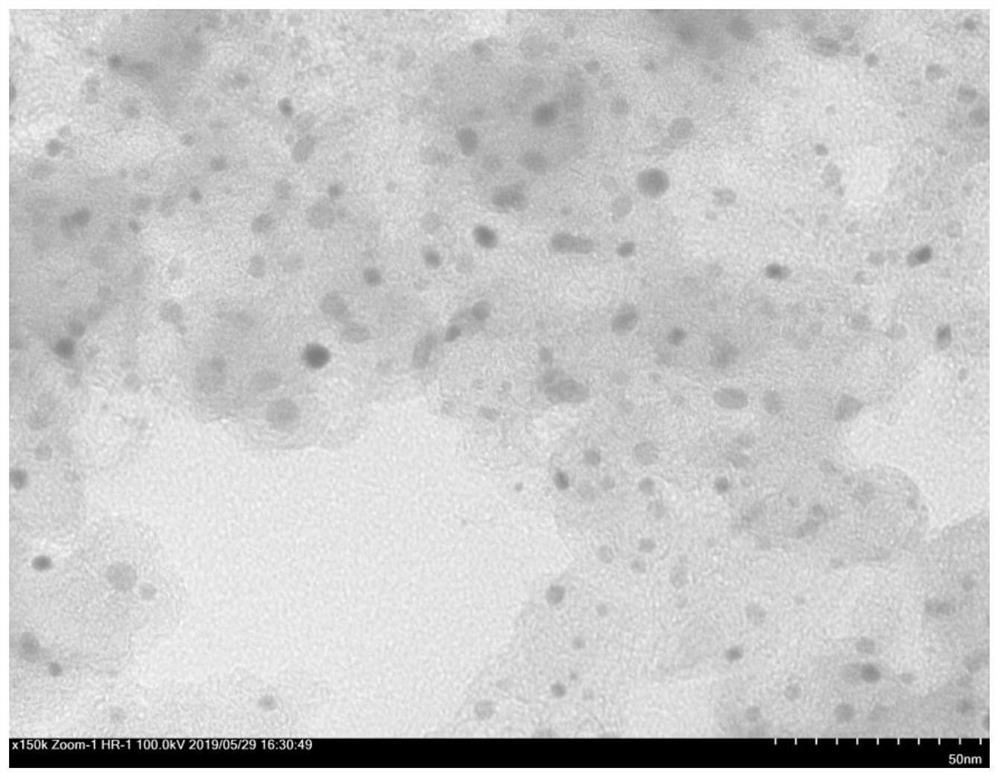

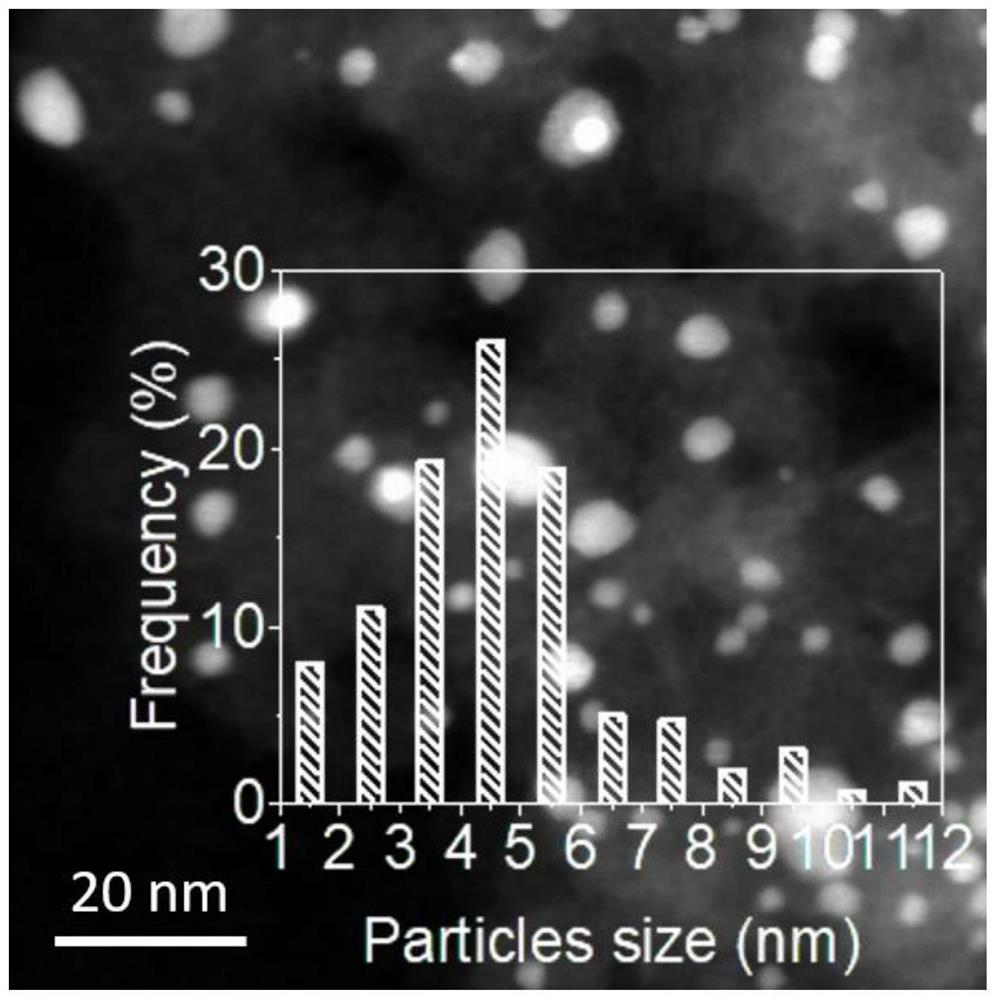

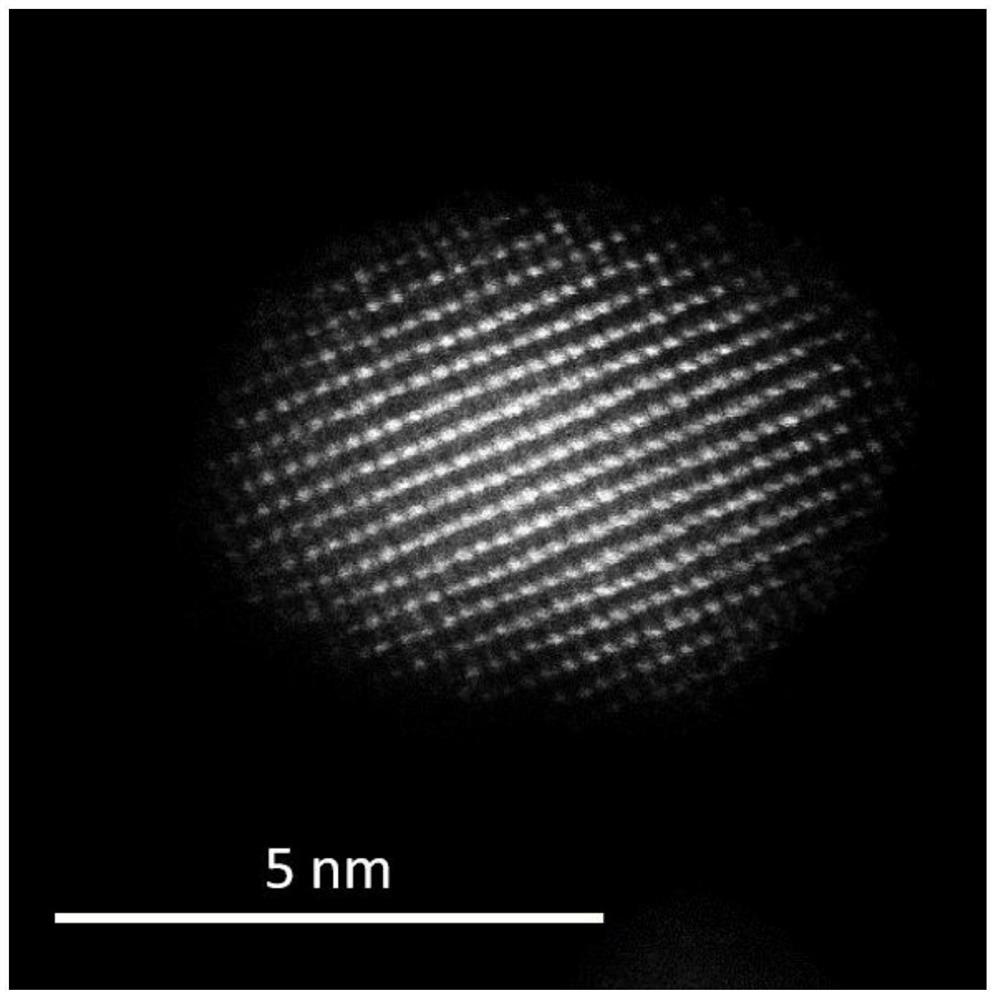

[0056] Characterization of highly ordered PtNi intermetallic compounds, the results are shown in Figure 1~4 . figure 1 The transmission electron microscope picture of the PtNi intermetallic compound prepared in Example 1 of the present invention shows that the PtNi intermetallic compound is evenly dispersed on the commer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com