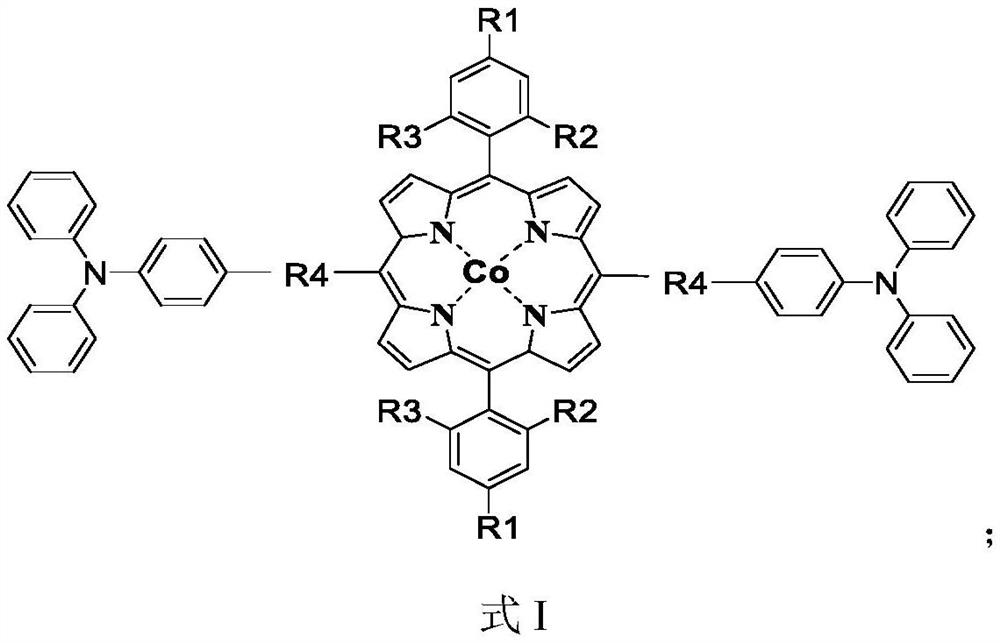

Triphenylamine cobalt porphyrin catalyst and preparation method and application thereof

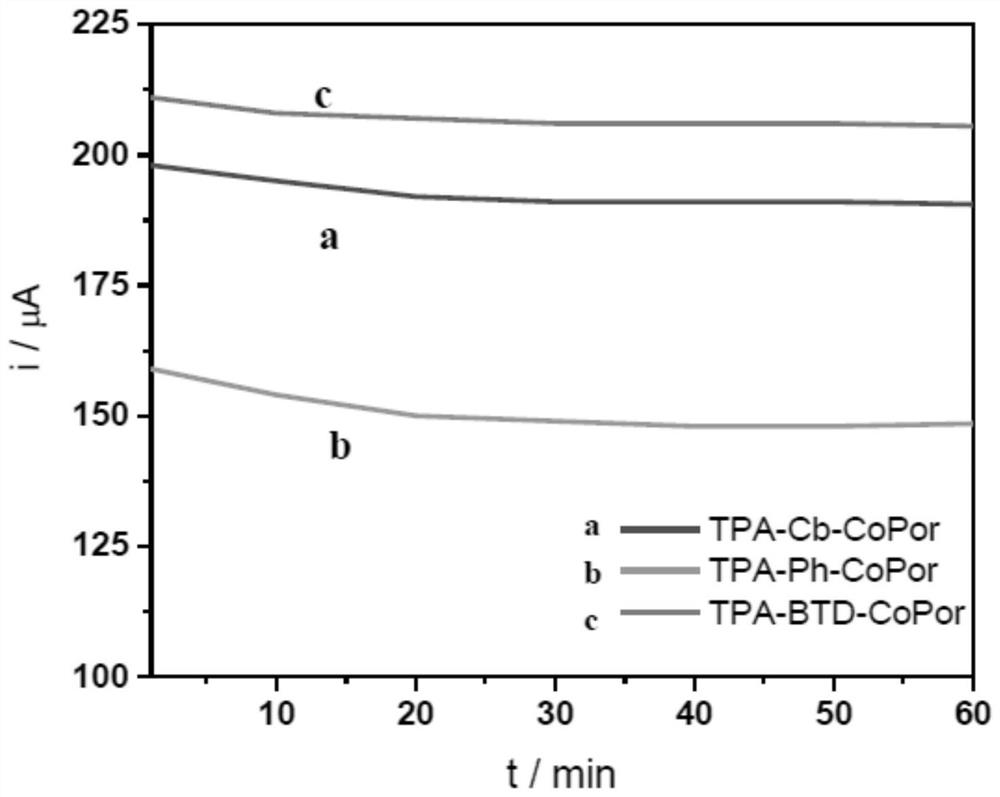

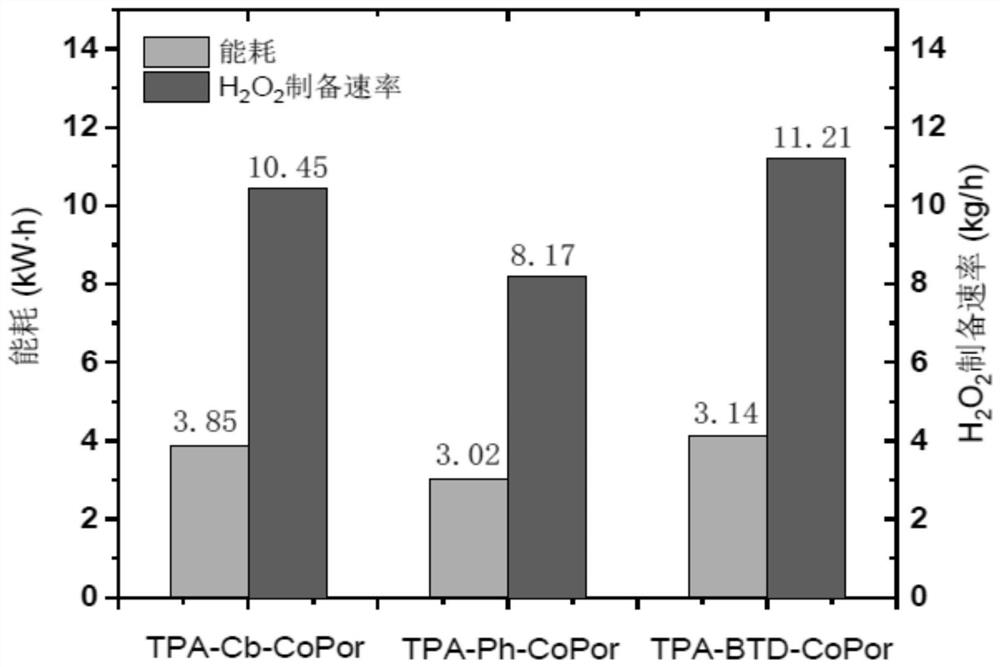

A triphenylamine-based cobalt porphyrin and catalyst technology, applied in the field of electrocatalytic oxygen reduction to produce hydrogen peroxide, can solve the problems of changing the concentration of protons on the catalytic interface, increasing the risk of explosion, and the impact of oxygen adsorption, and achieve good electrocatalysis Oxygen reduction activity, enhanced hydrogen peroxide selectivity, high hydrogen peroxide selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] (1) Synthesis of the first intermediate 6-(4-(diphenylamino)phenyl)-9-ethylcarbazole-3-carbaldehyde (Suzuki coupling reaction):

[0063] 1.5mmol (455mg) of 6-bromo-9-ethyl-9H-carbazole-3-carbaldehyde and 2mmol (579mg) of 4-(diphenylamino)phenylboronic acid were dissolved in 35mL of toluene, and 5mL of sodium carbonate solution (2M) was added, Stir for 1 minute, then add 200 mg tetrakis(triphenylphosphine)palladium(0). The system was refluxed at 95° C. for 45 hours under the protection of nitrogen. Then the mixed solution was washed with saturated saline solution, acid-washed with dilute hydrochloric acid, and extracted with dichloromethane. The organic phase was separated, dried over anhydrous sodium sulfate and spin-dried, and the crude product was purified by silica gel column chromatography, and the eluent was dichloromethane / n-hexane (2:1). 608.9 mg of a yellow solid product was obtained with a yield of 87%.

[0064] (2) Synthesis (condensation reaction) of the s...

Embodiment 2

[0076] (1) The first intermediate: the synthesis of 4-(4-(diphenylamino)phenyl)-benzaldehyde (Suzuki coupling reaction): the synthesis method is the same as the step (1) of Example 1, and the yield is 90%.

[0077] (2) The third intermediate: 5,15-bis(1-(4-(diphenylamino)phenyl)-(phenyl-4-yl))-10,20-bis(2,4,6- The synthesis (condensation reaction) of trimethylphenyl) porphyrin: synthetic method is with the step (3) of embodiment 1. Yield 8.0%, purple solid.

[0078] (3) Compound TPA-Ph-CoPor: 5,15-bis(1-(4-(diphenylamino)phenyl)-(phenyl-4-yl))-10,20-bis(2,4, Synthesis (coordination reaction) of 6-trimethylphenyl) cobalt (II) porphyrin: the synthesis method is the same as that of the compound TPA-Cb-CoPor in Example 1, with a yield of 94.0%, dark red solid.

[0079] The specific process is as follows:

[0080]

[0081] Preparation of carbon material-loaded triphenylamine-based cobalt porphyrin composite catalysts: respectively disperse a mixture of 3mg compound TPA-Ph-CoP...

Embodiment 3

[0085] (1) The first intermediate: 7-(4-(diphenylamino)phenyl)benzo[c][1,2,5]thiadiazole-4-carbaldehyde (g): the synthesis method is the same as in Example 1 Step (1), yield 88%.

[0086] (2) The third intermediate: 5,15-bis(3-(4-(diphenylamino)phenyl)-(2,1,3-benzothiadiazol-4-yl))-10,20 - two (2,4,6-trimethylphenyl) porphyrin (condensation reaction): synthetic method is the same as embodiment 1 step (3). Yield 12.3%, purple solid.

[0087] (3) Compound TPA-BTD-CoPor: 5,15-bis(3-(4-(diphenylamino)phenyl)-(2,1,3-benzothiadiazol-4-yl))-10 , the synthesis (coordination reaction) of 20-two (2,4,6-trimethylphenyl) cobalt (II) porphyrin: synthetic method is the same as embodiment 1 compound TPA-Cb-CoPor, productive rate 89%, dark red solid,

[0088] The specific process is as follows:

[0089]

[0090] Preparation of carbon material-supported triphenylamine-based cobalt porphyrin composite catalysts: respectively disperse a mixture of 3mg compound TPA-BTD-CoPor and 10mg carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com