AIoT-based operable intelligent barbecue robot

A robot and intelligent technology, applied in the field of grilled skewers, can solve the problems of high labor intensity, unfavorable large-scale, batch-scaled skewers, and a large amount of smoke, so as to improve work efficiency, facilitate remote monitoring, and high-efficiency The effect of efficient pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

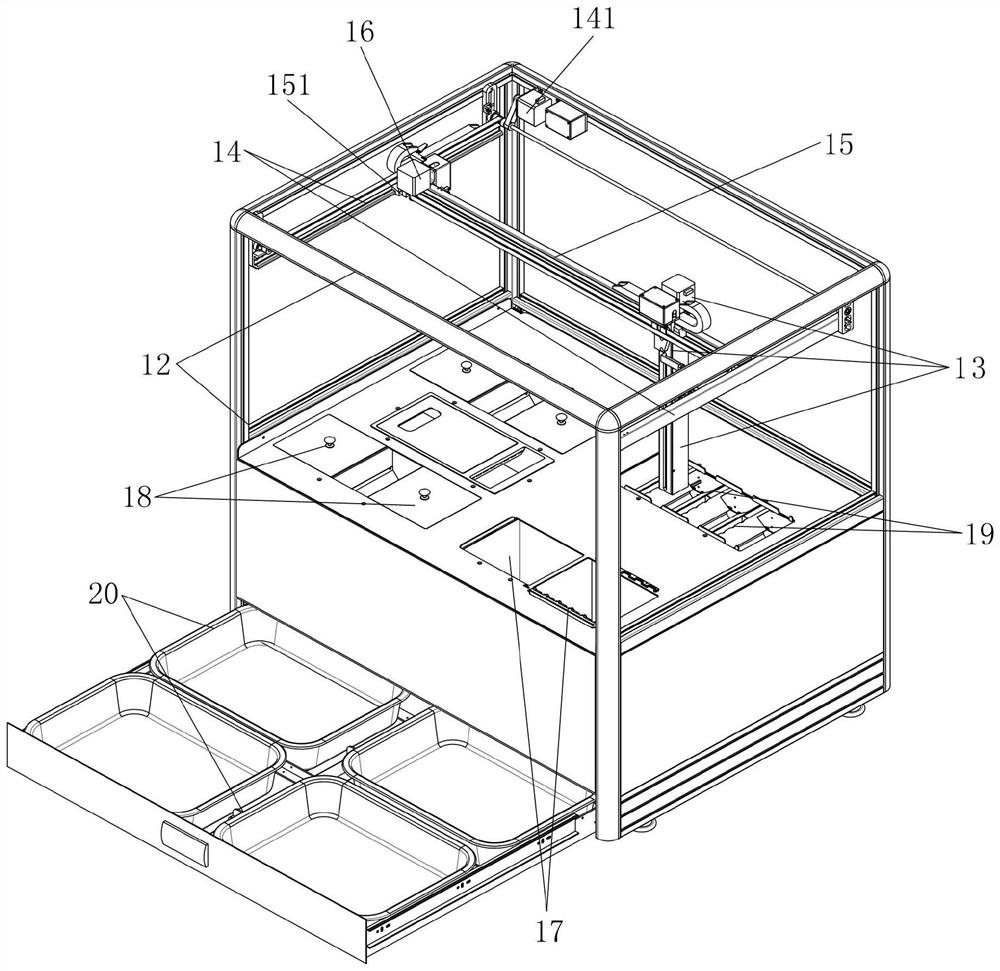

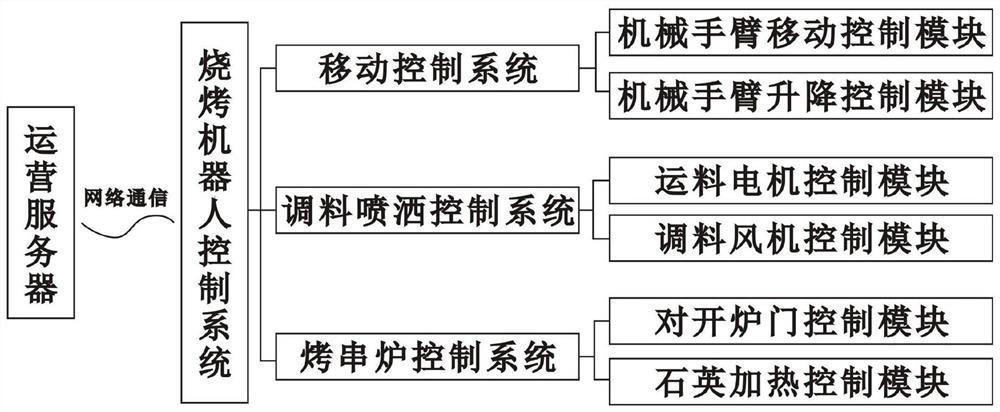

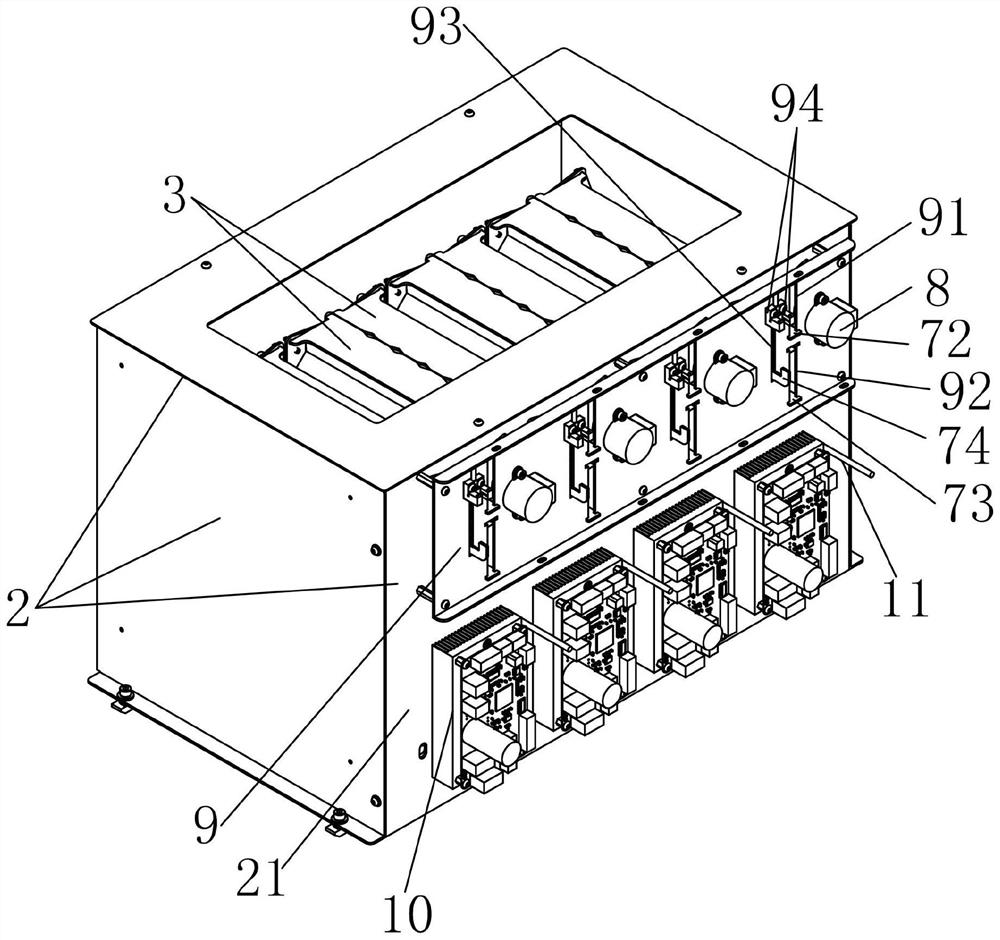

[0042] like Figure 1 to Figure 16 As shown, an AIoT-based intelligent barbecue robot includes a support frame 12 and a skewer handling manipulator 13. The top of the support frame 12 is provided with a two-axis movement system for driving the skewer handling manipulator 13 to move in the X-axis and Y-axis directions. The skewer handling manipulator 13 includes a Z-axis linear motor and a mechanical grabbing hand installed on the Z-axis linear motor. The bottom of the support frame 12 has a baking operation platform corresponding to the skewer handling manipulator 13, which is characterized in that: The layout on the industrial platform is provided with a skewer storage box 17, a seasoning spraying device 18 and a skewer roasting device 19. The two-axis moving system drives the skewer handling manipulator 13 to grab the skewers in the skewer storage box 17, seasoning spraying device 18, Grilled skewer roasting device 19 carries out assembly line operation operation motion. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com