Anti-deformation auxiliary tool for turning thin-wall end cover and turning method

An auxiliary tool and turning technology, which is applied in the direction of manufacturing tools, turning equipment, turning equipment, etc., can solve the problems that the product size tolerance and shape tolerance cannot be guaranteed, the nitriding position of the workpiece is easy to jump, and the product processing progress is affected. Solve the effects of clamping deformation, large contact area and anti-corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

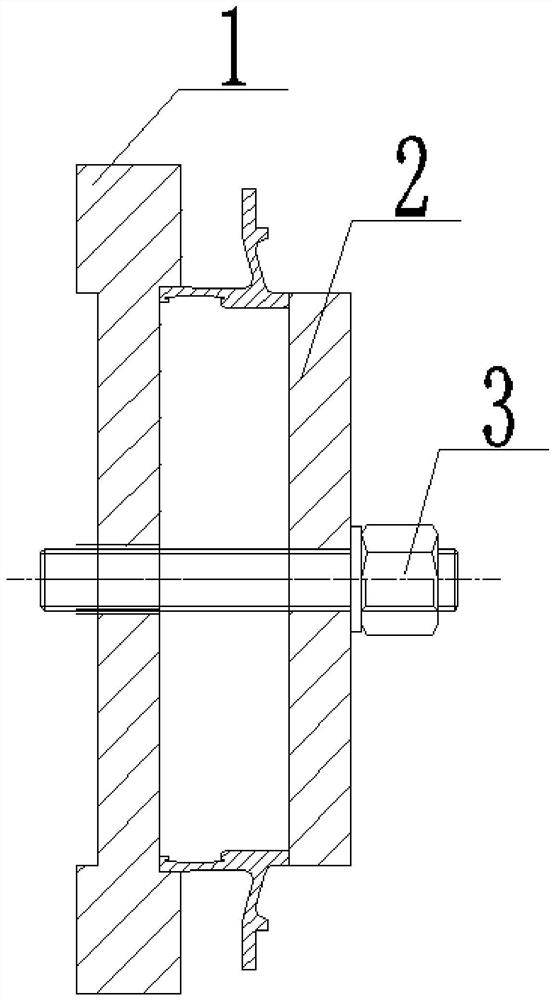

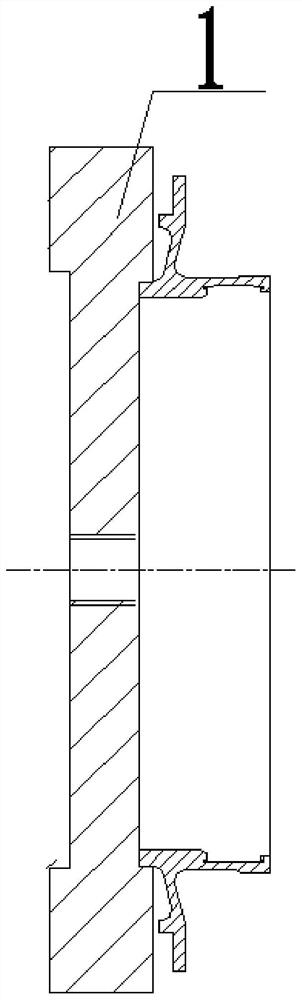

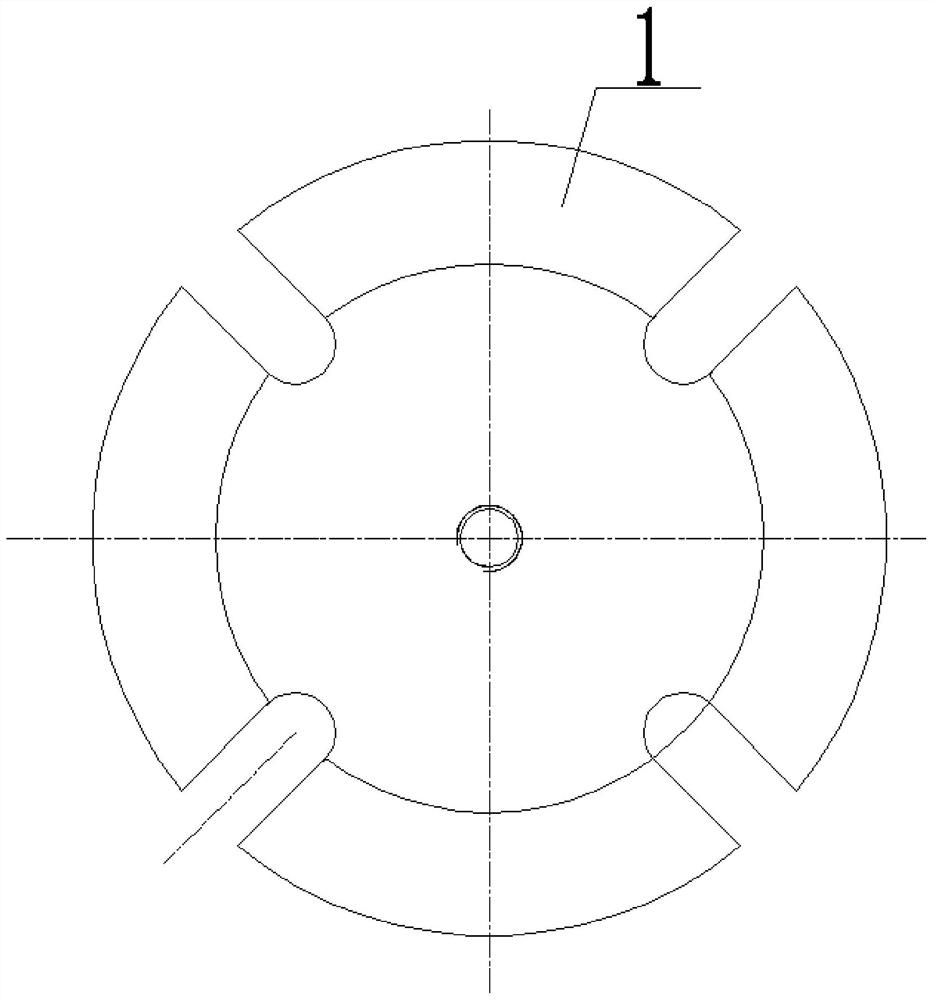

[0023] DETAILED DESCRIPTION One: Combination Figure 1 - Figure 5 In the present embodiment, the type of vehicle cutting wall end cover anti-deformed auxiliary tool, which includes a carpet 1, a pressure plate 2, and a clamping connector 3; the fetal 1 is a circular plate, the outer surface of the circular plate body. There is a ring protrusion, the thickness of the annular projections is larger than the thickness of the circular plate, and the center of the circular plate has an internal threaded hole, and the pressure plate 2 is a circular plate with a through hole, clamping the connecting member 3 end card On the pressure plate 2, the other end of the clamping connector 3 is threaded with the inner threaded hole of the carpet 1.

specific Embodiment approach 2

[0024] DETAILED DESCRIPTION 2: Combination Figure 1 - Figure 2 In this embodiment, the present embodiment is a rail-cutting wall end cover anti-deformed auxiliary tool, and the clamping connector 3 is a screw with a nut, and one end of the screw is threaded, the nut on the other end of the screw. On the pressure plate 2. Other components and connection methods are the same as those of the specific embodiments.

specific Embodiment approach 3

[0025] Detailed Embodiment 3: Combination figure 1 and Figure 5 In this embodiment, the present embodiment is a wire-shaped auxiliary tool, which further comprises a clamping spacer 4, a clamping spacer 4 is sleeved on a screw between the nut and the pressure plate 2. Other components and connections are the same as those in the specific embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com