Method for improving temperature resistance of vanadium-zirconium blue pigment produced from fused zirconia

A technology of fused zirconia and vanadium zirconium blue materials, applied in the direction of fibrous fillers, can solve the problems of unreachable and unsatisfactory temperature resistance effect, improve temperature resistance, improve physical and chemical properties, enrich color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

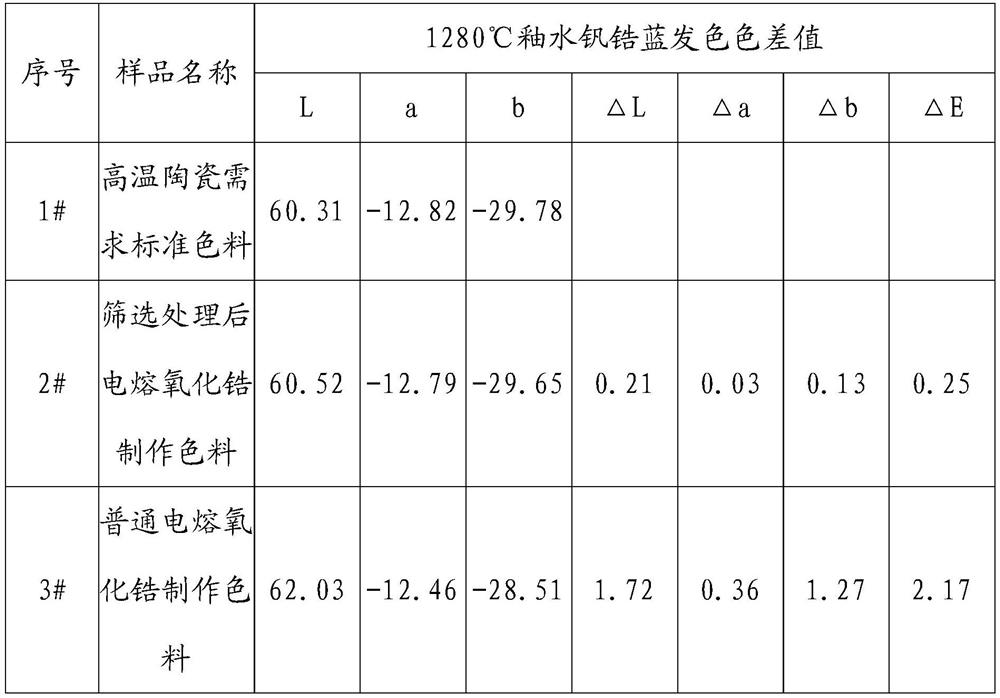

Examples

Embodiment 1

[0018] A method for improving the temperature resistance of vanadium-zirconium blue material produced by fused zirconia, comprising the following steps:

[0019] Step 1. Zircon sand screening treatment: use a 60M sieve to screen the zircon sand, and take part of the materials on the screen to obtain the screened zircon sand. The function of the screening is to optimize the composition of the zircon sand and reduce the impurity content;

[0020] Step 2, high-temperature smelting treatment: put the product obtained in step 1 in a high-temperature smelting furnace for smelting treatment at about 2500°C, and cool it with clean water after smelting. This link is the preparation process of fused zirconia for vanadium-zirconium blue material ;

[0021] Step 3, zirconia particle screening treatment: After the product of step 2 is dried at 200°C, it is screened with a 10M sieve, and part of the material on the sieve is taken to obtain the screened zircon sand. The screening function is...

Embodiment 2

[0025] A method for improving the temperature resistance of vanadium-zirconium blue material produced by fused zirconia, comprising the following steps:

[0026] Step 1. Zircon sand screening treatment: use a 120M sieve to screen the zircon sand, and take part of the materials on the sieve to obtain the screened zircon sand. The function of the screening is to optimize the composition of the zircon sand and reduce the impurity content;

[0027] Step 2. High-temperature smelting treatment: put the product obtained in step 1 into a high-temperature smelting furnace for smelting treatment at about 3000°C, and cool it with clean water after smelting. This link is the preparation process of fused zirconia for vanadium-zirconium blue material ;

[0028] Step 3, zirconia particle screening treatment: After the product of step 2 is dried at 300°C, it is screened with a 30M sieve, and part of the material on the sieve is taken to obtain the screened zircon sand. The screening function ...

Embodiment 3

[0032] A method for improving the temperature resistance of vanadium-zirconium blue material produced by fused zirconia, comprising the following steps:

[0033] Step 1. Zircon sand screening treatment: use a 100M sieve to screen the zircon sand, and take part of the materials on the screen to obtain the screened zircon sand. The function of the screening is to optimize the composition of the zircon sand and reduce the impurity content;

[0034] Step 2, high-temperature smelting treatment: the product obtained in step 1 is placed in a high-temperature smelting furnace for smelting treatment at about 2700°C, and after smelting, it is cooled with clean water to rapidly cool down the fused zirconia high-temperature melt;

[0035] Step 3, zirconia particle screening treatment: After the product in step 2 is dried at 280°C, it is screened with a 20M sieve, and part of the material on the sieve is taken to obtain the screened zircon sand. The screening function is mainly to select zi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com