Conductor lead for protection circuit and protection circuit comprising lead

A technology for protecting circuits and leads, applied in the field of conductor materials for electronic circuits, can solve problems such as product failure, product short circuit, product leakage, etc., achieve high surge capacity, low clamping voltage, and ensure the effect of not being damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

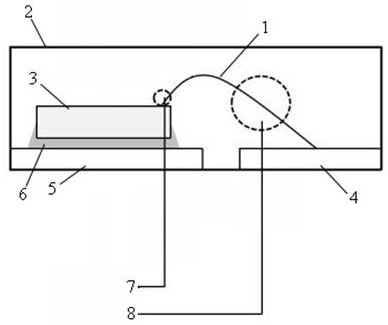

[0021] Such as figure 1 As shown, a protection circuit is connected to the protected chip (TVS chip 3) and the chip fixing bracket 5 through the conductive glue 6, and then the protected chip and the lead bracket 4 are connected through the lead wire 1, and finally the whole is packaged with epoxy resin 2 A circuit, forming a protection circuit for the protected chip; the surface of the protected chip connected to the lead 1 is coated with an aluminum layer, and the lead 1 is connected through the aluminum layer. Wherein, the diameter of the wire is 1.2 mil; the thickness of the aluminum layer is 2 μm.

[0022] The lead wire is made of copper alloy, and the ratio of the copper alloy raw material is 0.6% of zinc powder, 2.5% of nickel powder, 0.5% of zirconium powder, 0.4% of cerium powder, 0.6% of silicon powder, tin powder 0.06%, iron powder 0.3%, boron powder (powder after sieving) 0.2%, and the rest is copper powder, totaling 100%. The preparation method of the lead wire ...

Embodiment 2

[0030] Such as figure 1 As shown, a protection circuit is connected to the protected chip (TVS chip 3) and the chip fixing bracket 5 through the conductive glue 6, and then the protected chip and the lead bracket 4 are connected through the lead wire 1, and finally the whole is packaged with epoxy resin 2 A circuit, forming a protection circuit for the protected chip; the surface of the protected chip connected to the lead 1 is coated with an aluminum layer, and the lead 1 is connected through the aluminum layer. Wherein, the diameter of the wire is 1.2 mil; the thickness of the aluminum layer is 2 μm.

[0031]The lead wire is made of copper alloy, and the ratio of the copper alloy raw materials is 0.7% by weight of zinc powder, 2.8% of nickel powder, 0.6% of zirconium powder, 0.4% of cerium powder, 0.7% of silicon powder, tin powder 0.07%, iron powder 0.5%, boron powder (powder after sieving) 0.3%, the rest is copper powder, totaling 100%. The preparation method of the lead...

Embodiment 3

[0039] Such as figure 1 As shown, a protection circuit is connected to the protected chip (TVS chip 3) and the chip fixing bracket 5 through the conductive glue 6, and then the protected chip and the lead bracket 4 are connected through the lead wire 1, and finally the whole is packaged with epoxy resin 2 A circuit, forming a protection circuit for the protected chip; the surface of the protected chip connected to the lead 1 is coated with an aluminum layer, and the lead 1 is connected through the aluminum layer. Wherein, the diameter of the wire is 1.2 mil; the thickness of the aluminum layer is 2 μm.

[0040] The lead wire is made of copper alloy, and the ratio of the copper alloy raw material is 0.8% of zinc powder, 3.0% of nickel powder, 0.7% of zirconium powder, 0.5% of cerium powder, 0.7% of silicon powder, tin powder 0.07%, iron powder 0.7%, boron powder (powder after sieving) 0.3%, and the rest is copper powder, totaling 100%. The preparation method of the lead wire ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com